Flavored hot pickled mustard tubers and preparation method thereof

A technology of mustard and flavor, applied in the field of flavored mustard and its preparation, can solve the problems of low crispness of mustard, lack of inherent fragrance of green mustard, poor taste, etc., and achieve the effects of crisp taste, improved flavor of mustard, and improved commerciality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

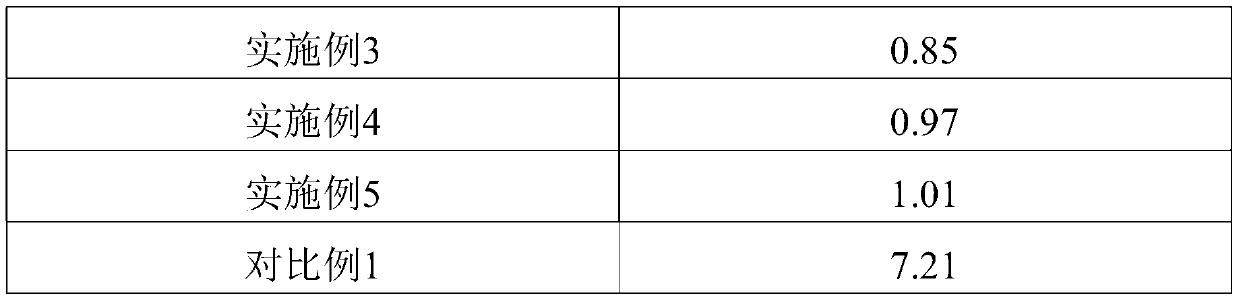

Embodiment 1

[0031] The flavored pickled mustard of this embodiment comprises the following raw materials by weight: 100 parts of green cabbage head, 80 parts of soaking liquid, 0.05 part of phytic acid, 0.1 part of sodium erythorbate, 0.1 part of disodium stannous citrate, 0.02 part of citric acid, lactic acid bacteria 2 parts, 0.1 part of sodium alginate, 3 parts of protease, 2 parts of table salt;

[0032] Among them, the soaking solution is made of the following raw materials in parts by weight: 2 parts of alpine red pepper, 3 parts of garlic, 2 parts of star anise, 1 part of cumin, 2 parts of cinnamon, 2 parts of Chinese prickly ash, 1 part of pepper, 2 parts of green onion, 3 parts of white wine 1.2 parts of ginger slices, 1 part of lemon slices, 1 part of chili powder, and 1 part of monosodium glutamate; Put white wine, ginger slices, and lemon slices in a boiling kettle, add purified water 5 times the weight of the raw materials in the boiling kettle, boil for 12 minutes, filter af...

Embodiment 2

[0045] The flavored pickled mustard of this example is made from the following raw materials in parts by weight: 150 parts of green cabbage heads, 120 parts of soaking liquid, 1 part of phytic acid, 0.3 parts of sodium erythorbate, 0.3 parts of disodium stannous citrate, 0.05 parts of citric acid, lactic acid bacteria 4 parts, 0.2 parts of sodium alginate, 6 parts of protease, 4 parts of table salt;

[0046]Among them, the soaking liquid is made of the following raw materials in parts by weight: 6 parts of alpine red pepper, 6 parts of garlic, 4 parts of star anise, 3 parts of cumin, 5 parts of cinnamon, 5 parts of Chinese prickly ash, 3 parts of pepper, 6 parts of green onion, 7 parts of white wine 3.5 parts of ginger slices, 4 parts of lemon slices, 3 parts of chili powder, and 2 parts of monosodium glutamate; Put white wine, ginger slices, and lemon slices in a boiling pot, add pure water 10 times the weight of the raw materials in the boiling pot, boil for 20 minutes, filt...

Embodiment 3

[0060] The flavored pickled mustard of this embodiment is made from the following raw materials in parts by weight: 125 parts of green cabbage heads, 100 parts of soaking liquid, 0.07 parts of phytic acid, 0.2 parts of sodium erythorbate, 0.2 parts of disodium stannous citrate, 0.035 parts of citric acid, lactic acid bacteria 3 parts, 0.15 parts of sodium alginate, 4.5 parts of protease, 3 parts of table salt;

[0061] Among them, the soaking liquid is made of the following raw materials in parts by weight: 4 parts of alpine red pepper, 4.5 parts of garlic, 3 parts of star anise, 2 parts of cumin, 3.5 parts of cinnamon, 3.5 parts of Chinese prickly ash, 2 parts of pepper, 4 parts of green onion, 5 parts of white wine 2 parts of ginger slices, 2.5 parts of lemon slices, 2 parts of chili powder, and 1.5 parts of monosodium glutamate; Put white wine, ginger slices, and lemon slices in a boiling pot, add pure water that is 8 times the weight of the raw materials in the boiling pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com