Smoke-free and sulfur-free firework oxidant and preparation method thereof

A technology of oxidant and sulfur fireworks, applied in offensive equipment, explosive processing equipment, explosives, etc., to achieve the effect of fewer steps, no discharge of three wastes, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

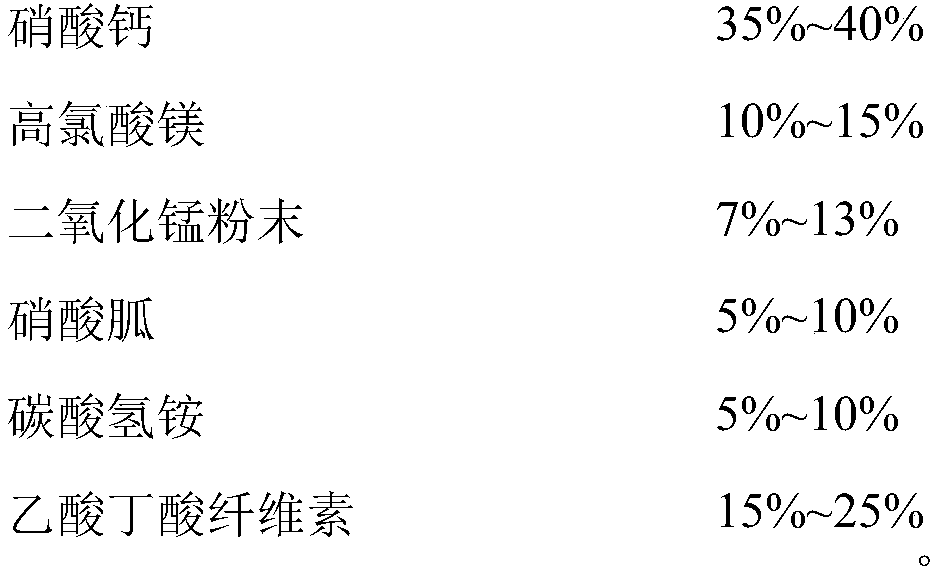

[0026] A kind of smokeless and sulfur-free fireworks oxidant, the mass percentage of its components is as follows:

[0027]

[0028] 35g calcium nitrate, 15g magnesium perchlorate and 10g ammonium bicarbonate are added in 150g ethyl acetate (40%) / water mixed solvent, be heated to 65 ℃, continuously stir until solute dissolves and obtain solution A; Under stirring state, Add 8g of guanidine nitrate to 35g of ethanol, keep stirring to obtain solution B; join solution A in solution B, after stirring at 250rpm speed for 20 minutes, obtain mixed solution C; mix 20g cellulose acetate butyrate with 12g manganese dioxide Mix the powder mechanically evenly, add the mixed solution C to it, and continue stirring at a rate of 100rpm while pouring, and continue stirring for 50 minutes after pouring, to obtain a uniform micelle with moderate hardness; the obtained uniform micelle with moderate hardness The solids were granulated with a twin-screw granulator, and vacuum-dried at 60°C for ...

Embodiment 2

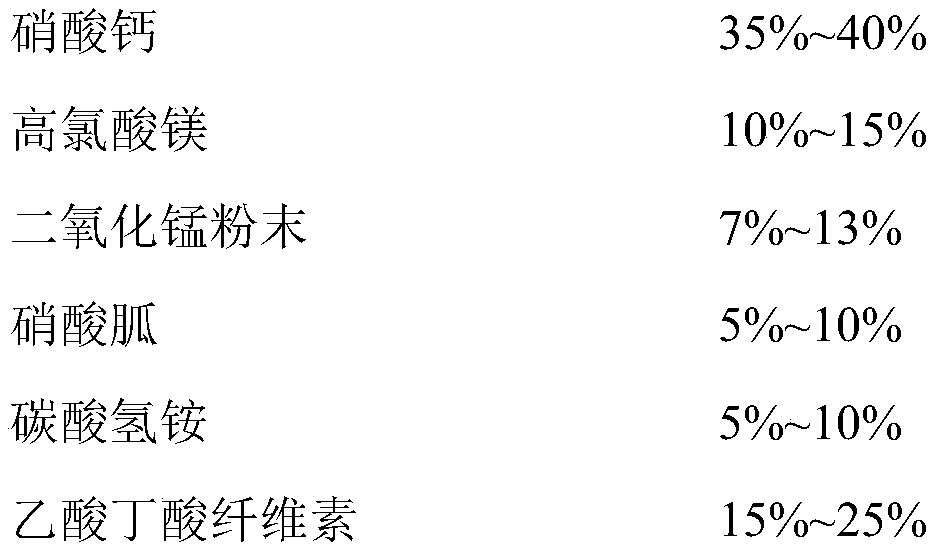

[0030] A kind of smokeless and sulfur-free fireworks oxidant, the mass percentage of its components is as follows:

[0031]

[0032] 370g calcium nitrate, 120g magnesium perchlorate and 100g ammonium bicarbonate are added in 1300g ethyl acetate (30%) / water mixed solvent, be heated to 50 ℃, stir continuously until solute dissolves and obtain solution A; Step 3, stirring Under the state, add 100g guanidine nitrate to 350g ethanol, keep stirring, obtain solution B; Add solution A in solution B, after stirring at 200rpm speed for 30 minutes, obtain mixed solution C; Mix 230g cellulose acetate butyrate with 80g The manganese dioxide powder is mechanically mixed evenly, and the mixed solution C is added therein, continuously stirred at a rate of 80 rpm while pouring, and continued to stir for 60 minutes after pouring, to obtain a uniform gelatinous mass with moderate hardness; The uniform micelles are granulated with a twin-screw granulator, and vacuum-dried at 60°C for 12 hours ...

Embodiment 3

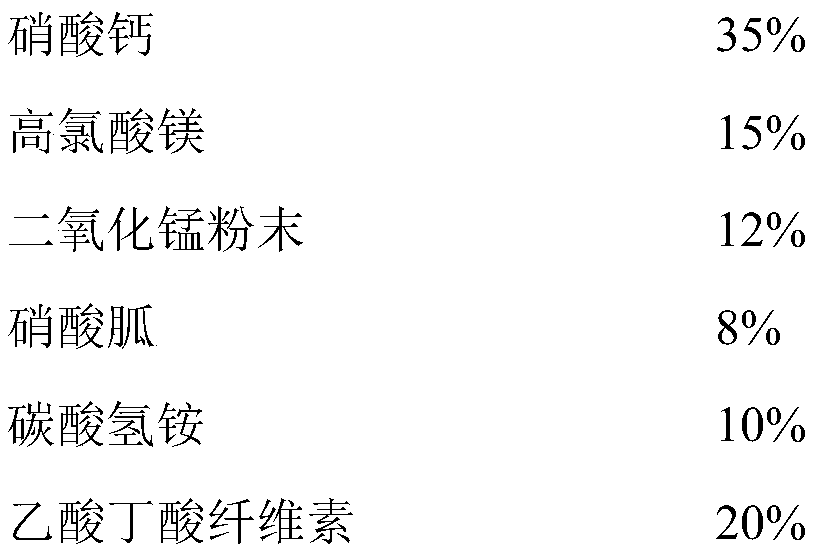

[0034] A kind of smokeless and sulfur-free fireworks oxidant, the mass percentage of its components is as follows:

[0035]

[0036]

[0037] Add 4kg of calcium nitrate, 1.1kg of magnesium perchlorate and 0.5kg of ammonium bicarbonate into 18kg of ethyl acetate (50%) / water mixed solvent, heat to 80°C, and stir continuously until the solute dissolves to obtain solution A; Next, add 1 kg of guanidine nitrate to 3 kg of ethanol and continue to stir to obtain solution B; add solution A to solution B and stir at 300 rpm for 15 minutes to obtain mixed solution C; mix 2.5 kg of cellulose acetate butyrate with 0.9 kg of manganese dioxide powder is mechanically mixed evenly, and the mixed solution C is added therein, and continuously stirred at a rate of 120rpm while pouring, and continued to stir for 60 minutes after pouring, to obtain a uniform gelatinous mass with moderate hardness; The uniform micelles were granulated with a twin-screw granulator, and vacuum-dried at 60°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com