A Deep Explosion Fracturing Method in a Radial Slim Hole

A technology of explosive fracturing and wellbore, which is applied in the direction of wellbore/well components, earthwork drilling and production, and mining fluid, etc. It can solve the problems of inability to effectively transform reservoirs near the wellbore, high fluidity of fluid explosives, and instability of liquid explosives To achieve the effect of improving seepage characteristics of reservoir, lower drilling cost and improving seepage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

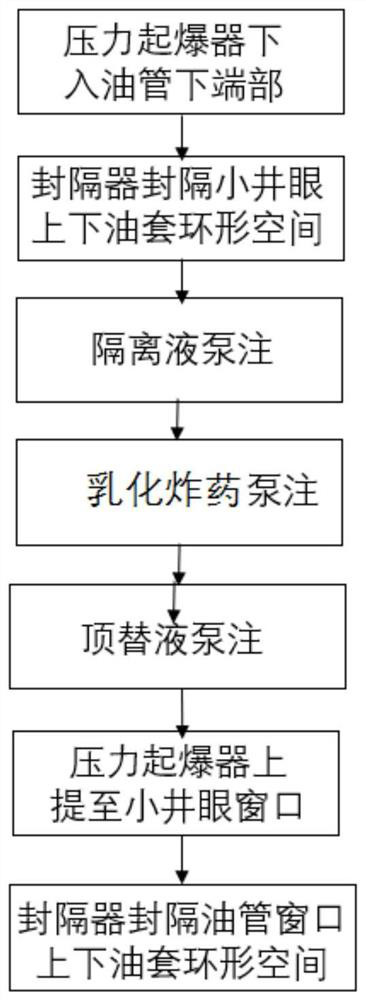

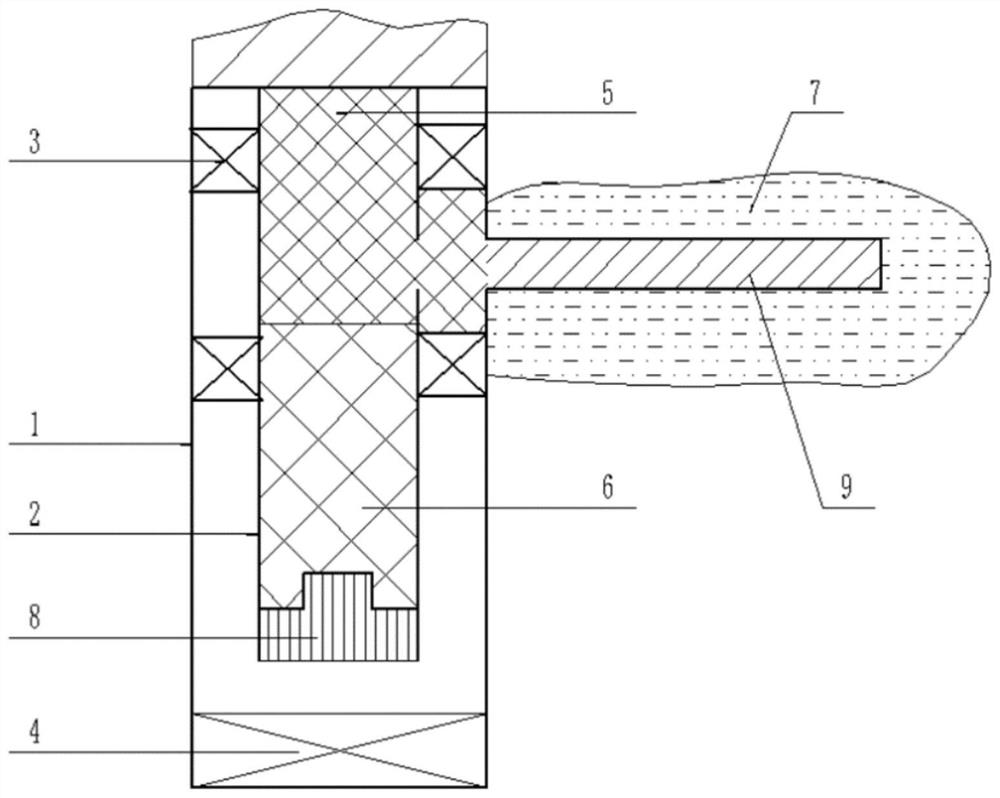

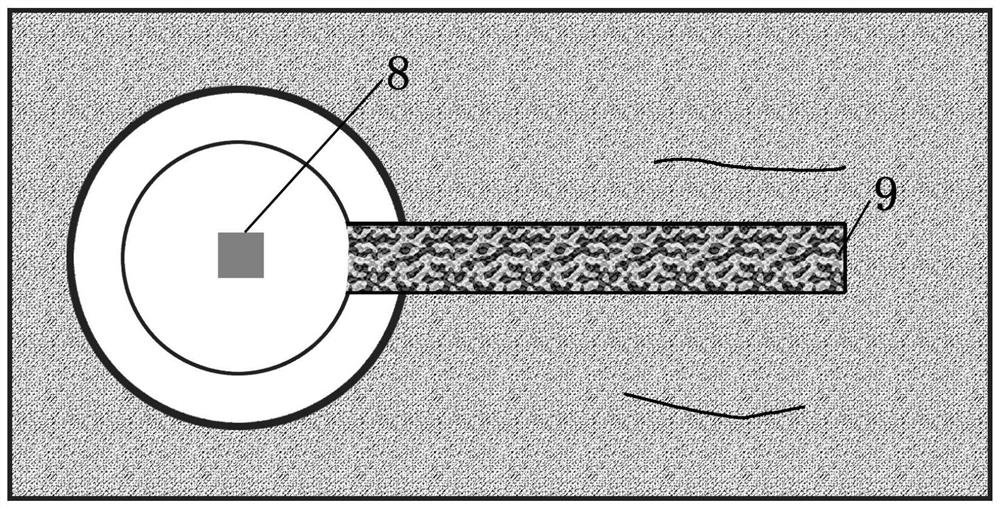

[0042] A deep burning fracturing method for radially small wells in the fracturing modification of oil and gas lamination, such as figure 1 , figure 2 As shown, the use of emulsion explosives pumps into the target small well eye section, and the steps are as follows:

[0043] Step 1, in the wellbore sleeve, add the pressure detonator, seal the oil pipe shoe. Pressure detonators use shear pins to fix the hitter detonator. The pressure startup pressure is set according to the emulsified explosive pump pressing pressure used in the construction.

[0044] Step 2, add the packer, and the construction target radial small oil jet space, the upper and lower packer distance is 1m distance radial small well eye oyster tube window.

[0045]Step 3, the ground pump group pumps the isolation liquid. Pumping the isolation liquid, the impurities in the tubing can be cleaned, and the emulsion explosives are contaminated. At the same time, the isolation fluid is injected into the tubing shoe to the...

Embodiment 2

[0064] A deep blast fracturing method for radially small wellbore in the oil-gas layer fracturing modification, as described in Example 1, in the first and lower packer, the upper and lower packer The distance from the tubing window is 0.8m.

Embodiment 3

[0066] A deep blast fracturing method for radially small wellbore in the oil-gas layer fracturing modification, as described in Example 1, in the first and lower packer, the upper and lower packer The distance of the tubing window is 1.2m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com