A method for improving the grinding efficiency of permanent magnet ferrite calcined material

A technology of permanent magnet ferrite and calcined material, which is applied in grain processing, etc., can solve the problems of high cost, shortened grinding time, narrow application range, etc., and achieve the effect of improving grinding efficiency, improving grinding efficiency, and reducing surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

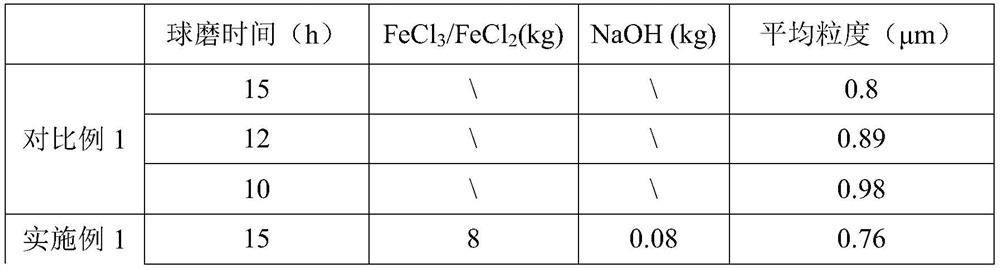

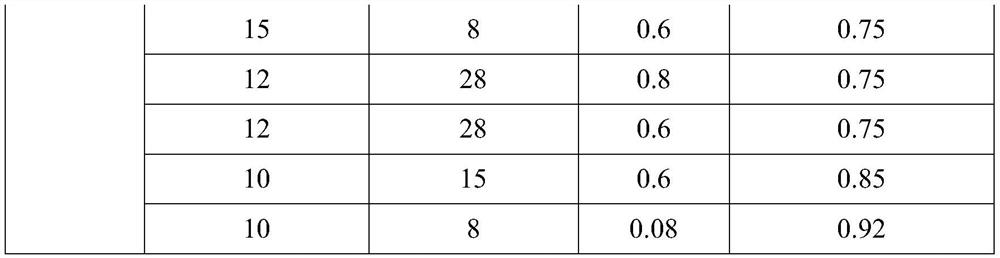

[0022] This embodiment includes the following steps:

[0023] Put 6 parts of the same calcined material (800kg each, with an average particle size of 6±0.2μm) into the ball mill respectively, add different amounts of ferric chloride or ferrous chloride, and add 1200kg of water, Equal-diameter steel balls 4000kg; after ball milling for 10-15 hours, add 0.08kg-0.8kg sodium hydroxide to the ball mill respectively, and then ball mill for 5 minutes, mix the slurry evenly, and then discharge and precipitate.

[0024] Take a small amount of slurry and bake it on an electric furnace until the water in the slurry is completely removed, disperse the powder with a proofer, pass the powder through an 80-mesh sieve, and test the average particle size of the powder with a WLP-208 average particle size tester. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com