Stable motor base for numerical control machine tool

A technology of CNC machine tools and motors, which is applied in the directions of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of poor disassembly convenience, shortened life, poor use effect, etc., to improve the heat dissipation effect and increase the heat dissipation. area, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

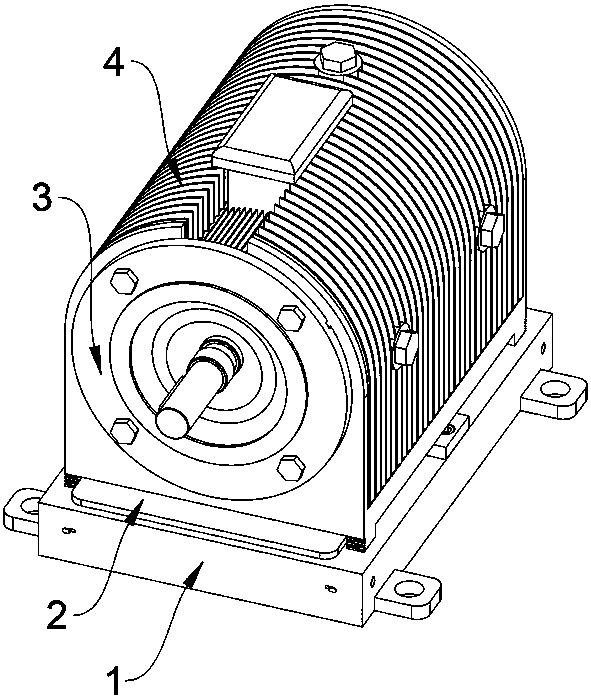

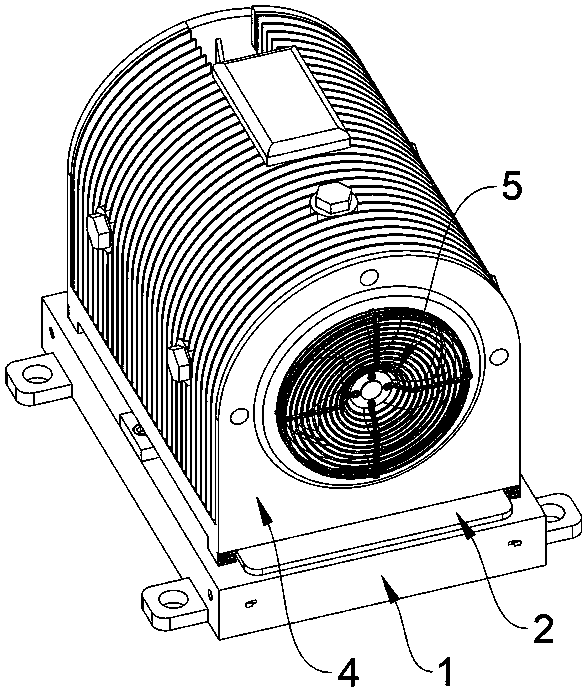

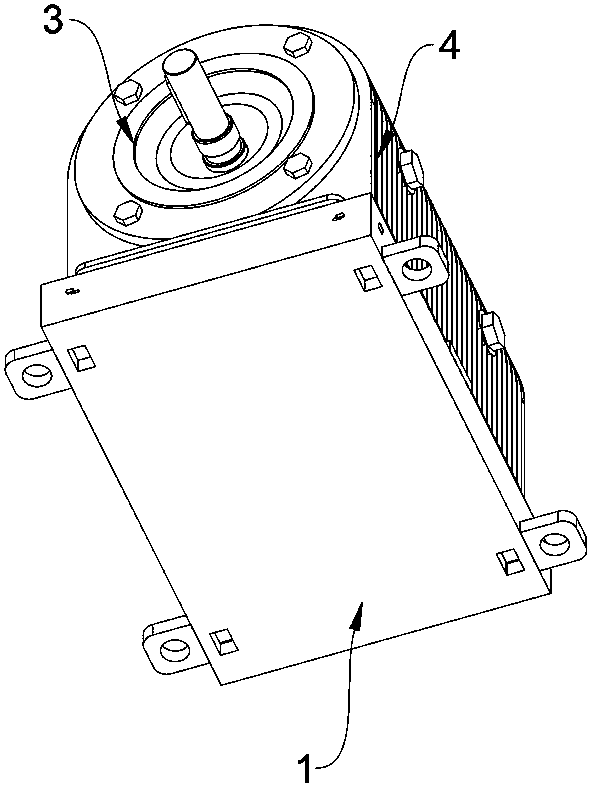

[0042] as attached figure 1 to attach Figure 12 Shown:

[0043] The present invention provides a stable motor base for numerically controlled machine tools, comprising: a fixed base 1; the fixed base 1 is designed as a rectangular structure, and both sides of the fixed base 1 are symmetrically provided with four bolt limit ears, and the top side of the fixed base 1 Two height-limiting pads 101 are fixed with symmetrical bolts at the middle position, and the height-limiting pads 101 are designed with a replaceable height structure, which is convenient for controlling the installation height of the heat dissipation fixing piece 4 by replacing the height-limiting pads 101 of different thicknesses, thereby The height adjustment of the motor 3 is realized; the upper limit of the fixed base 1 is equipped with a heat dissipation fixing piece 4, and the inner side of the heat dissipation fixing piece 4 is embedded with a motor 3, and the heat dissipation fixing piece 4 adopts a shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com