A device for accurately proportioning and feeding straw board surface materials

A technology of feeding device and straw board is applied in the direction of wood processing appliances, household appliances, other household appliances, etc., to achieve the effects of improving quality, realizing controllability, optimizing control and stability

Active Publication Date: 2022-05-31

铜陵万华禾香板业有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is to design a device for accurately proportioning and feeding the surface layer of straw slabs to solve the problem of the material accumulation area of the existing discharge screw at a relatively high speed. Will not be reduced due to centrifugal force, ensuring the accuracy of the ratio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] Furthermore, the terms "installed", "set up", "provided with", "connected", "connected", "socketed" should be construed broadly. E.g,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

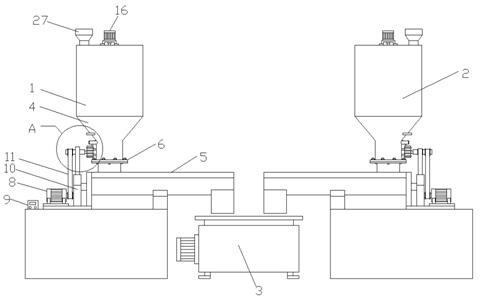

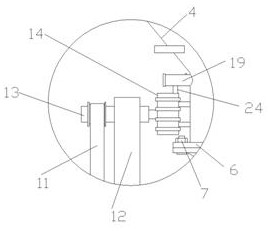

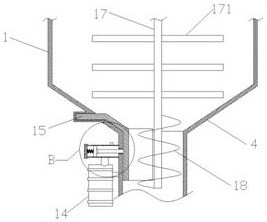

The invention relates to the technical field of straw board production, in particular to a feeding device for accurately proportioning the surface material of straw boards, comprising a wooden surface bunker, a straw shaving bin, and a scraper conveyor. The wooden surface bunker and the straw shaving bin are symmetrical. It is set that the bottom ends of the wooden surface silo and the straw shaving silo are connected with a tapered discharge pipe, and an auger conveyor is fixed below the wooden surface silo and the straw shavings silo, and the conical discharge pipe The feed pipe is connected with the feed port of the auger conveyor, the discharge port of the auger conveyor is arranged directly above the feed end of the scraper conveyor, and a first motor is arranged outside the feed port of the auger conveyor, A frequency converter is fixed on the outside of the first motor; the present invention can not only realize the controllability of the material ratio of the surface layer of the straw board through the frequency converter, but also ensure that the transportation speed of the auger conveyor is relatively fast. The accuracy of raw materials ensures the quality of the straw board produced.

Description

Precise proportioning feeding device for straw board surface material technical field The present invention relates to the technical field of straw board production, be specifically related to a kind of straw board surface layer material accurate proportioning charging device set. Background technique Traditional straw particle board surface material is made up of wood fine material and straw wood shavings, generally straw shavings and wood fine material The processing is divided into independent sections, which are collected into the same silo after drying, and it is difficult to achieve wood and straw materials according to The ratio of process requirements often results in the instability of the quality of the straw board. In view of the fact that the existing straw board cannot be added according to the process requirements The quality problems caused by the material, most companies use the assembly with frequency conversion control of the discharge screw, by ch...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27N3/02B27N3/18

CPCB27N3/02B27N3/18Y02P70/10

Inventor 刘建秋李奎周二高魏坚彭江袁波耿亮代庆洪

Owner 铜陵万华禾香板业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com