Three-dimensional printing method at room temperature and three-dimensional printing device

A three-dimensional printing, room temperature technology, applied in coating devices, manufacturing auxiliary devices, manufacturing tools, etc., can solve problems such as molding failure and insufficient strength, and achieve the effect of avoiding warping deformation and printing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

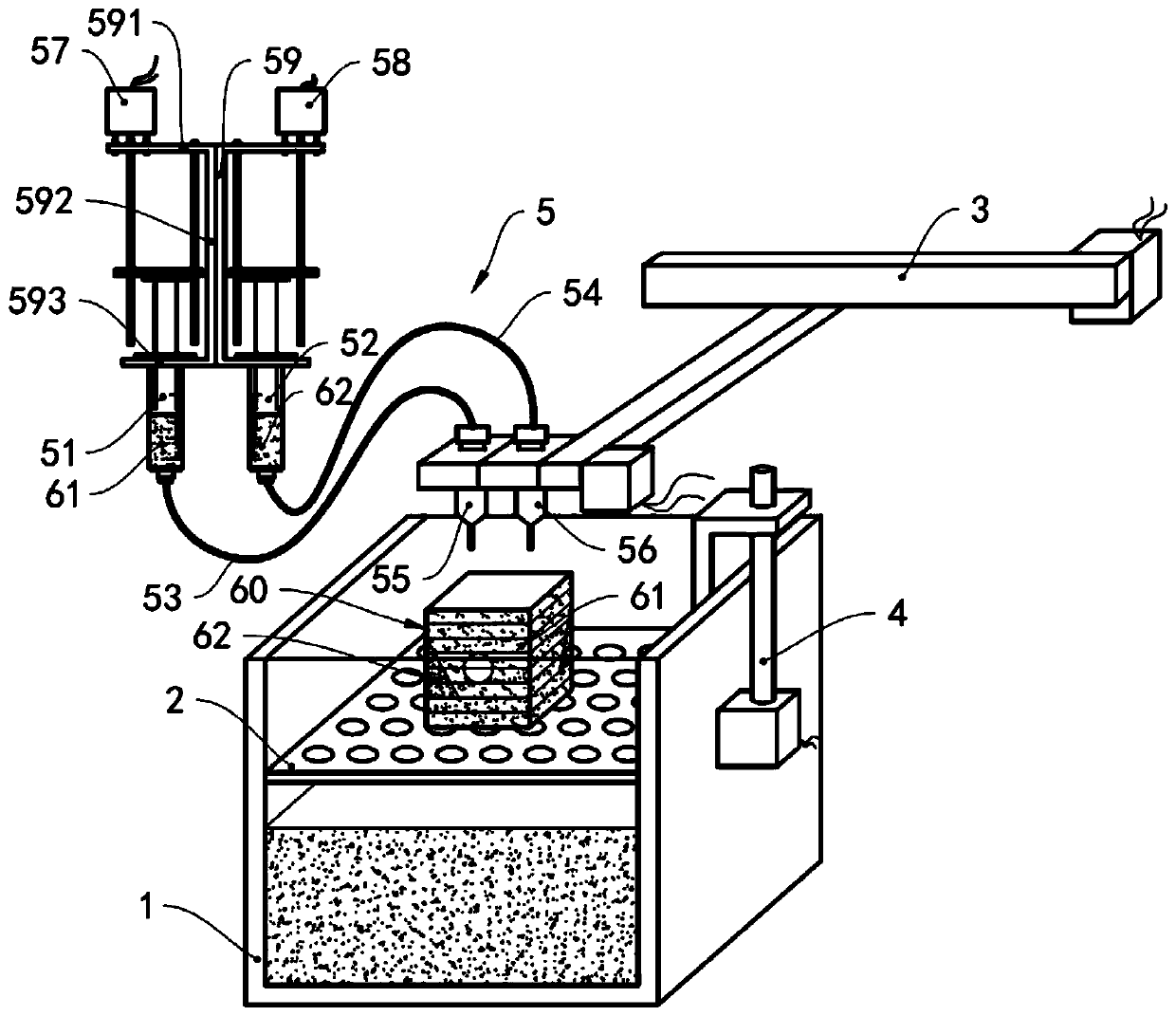

[0021] see figure 1 , the three-dimensional printing device of this embodiment includes a liquid storage tank 1 , a forming platform 2 , a horizontal motion driving device 3 , a vertical motion driving device 4 and a double nozzle mechanism 5 .

[0022] The double nozzle mechanism 5 includes a consumable material injector 51, a support material injector 52, a first infusion tube 53, a second infusion tube 54, a consumable print nozzle 55, a support material print nozzle 56, a first extrusion drive device 57, a second extrusion drive device 58 and syringe mount 59.

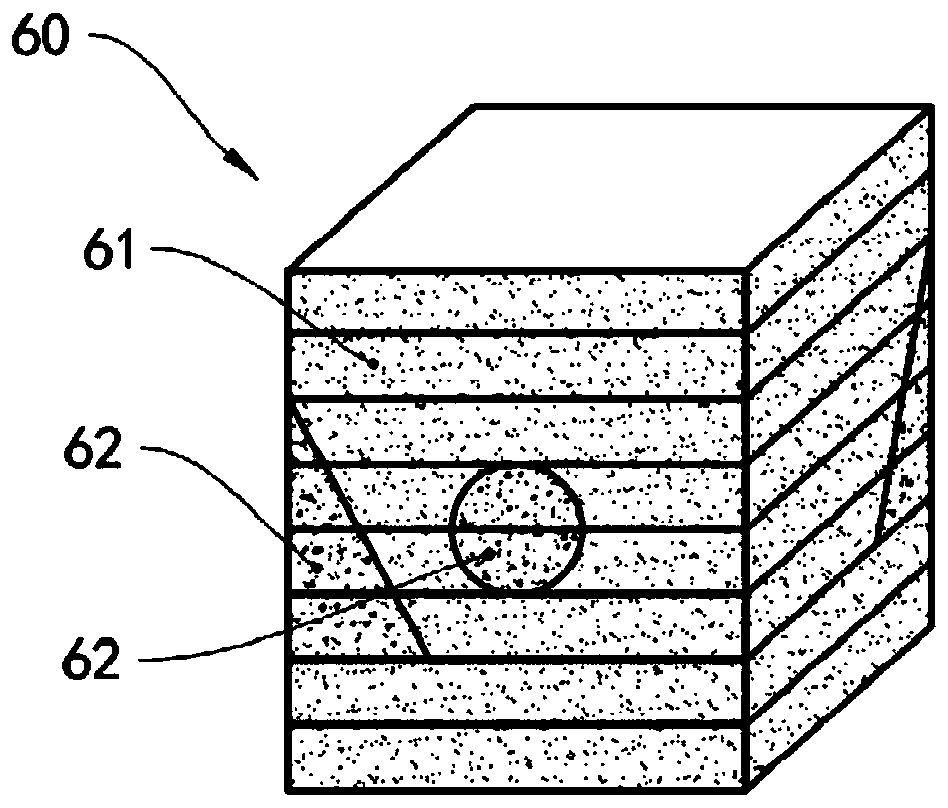

[0023] The consumable injector 51 communicates with the consumable printing nozzle 55 through the first liquid delivery tube 53 , and the support material injector 52 communicates with the support material printing nozzle 56 through the second fluid delivery tube 54 . The consumables injector 51 is used to store polycarbonate gel 61, which is prepared by dissolving polycarbonate powder of printing consumables with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com