A kind of graphene-Schiff base nickel compound for solid propellant and preparation method thereof

A solid propellant, Schiff base nickel technology, applied in offensive equipment, non-explosive/non-thermal agent components, explosives, etc., to improve the effect of catalytic combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

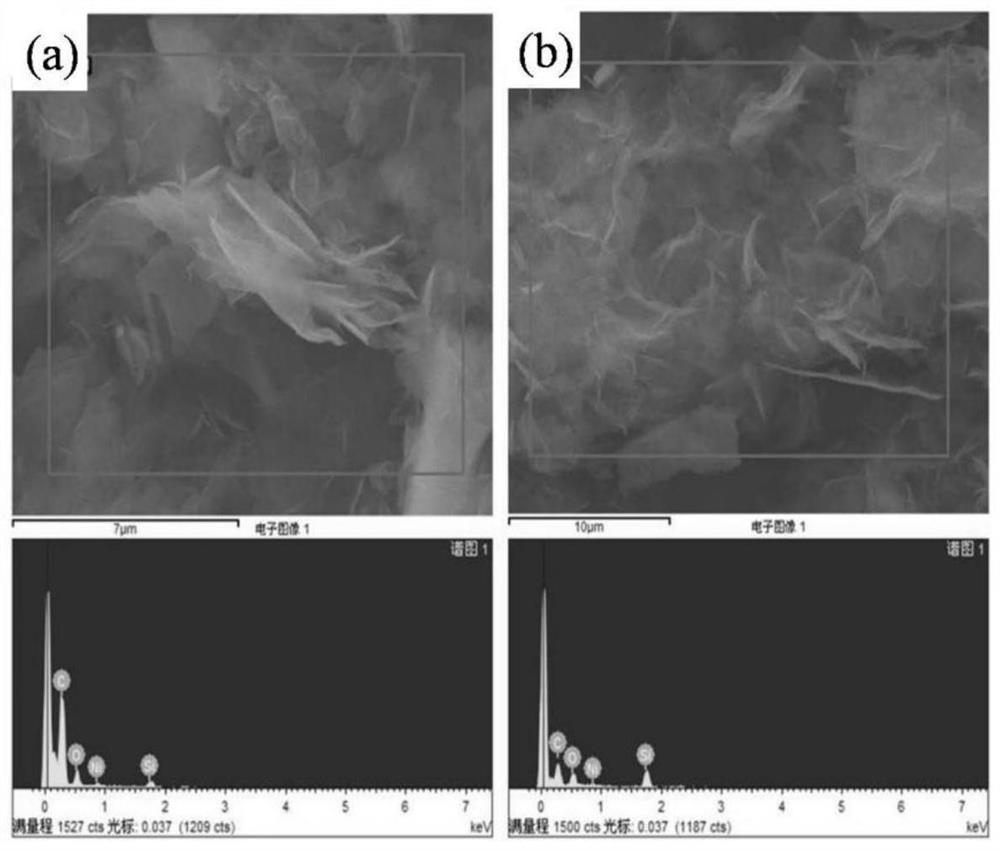

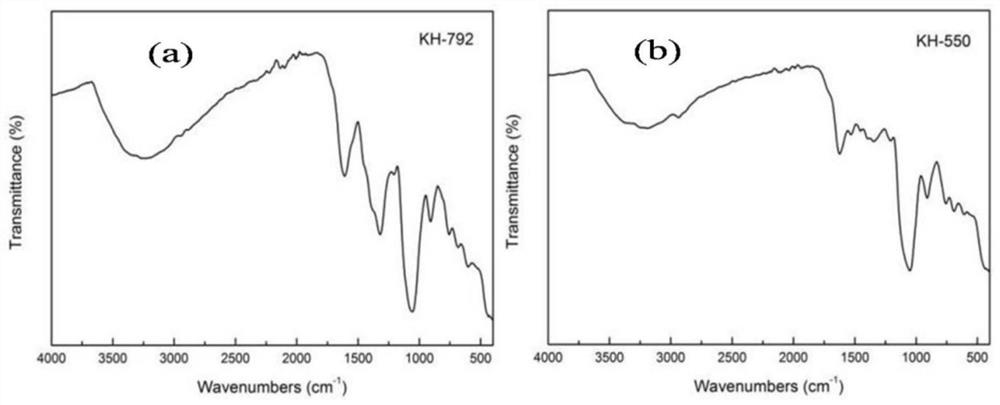

[0022] The morphology was characterized by a Quanta600 scanning electron microscope from Quantachrome, USA, and the infrared characterization was performed by a Tensor27 Fourier transform infrared spectrometer from Bruker, Germany.

[0023] Synthesis of Graphene-Schiff Base Nickel Composite

[0024] (1) Synthesis of Aminated Graphene:

[0025] Place the ultrasonically dispersed graphene oxide ethanol dispersion in a three-necked flask, and add an appropriate amount of γ-aminopropyltriethoxysilane KH550 or N-β-(aminoethyl)-γ-aminopropyltrimethoxy Base silane KH792 ethanol solution, reacted under reflux conditions for 2h, cooled to room temperature after the reaction, collected by centrifugation and washed with ethanol to obtain aminated graphene. Among them, KH550

[0026] Or the mass ratio of KH-792 to graphene oxide is 15;

[0027] (2) Synthesis of graphene-Schiff base ligands:

[0028] Place the aminated graphene ethanol dispersion synthesized in step (1) in a three-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com