Magnetic capsaicin molecularly imprinted polymer and preparation method thereof

A molecular imprinting and capsaicin technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as unfavorable trace detection, increase analysis time, template molecule leakage, etc., to shorten processing time, simplify pretreatment steps, Identify fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

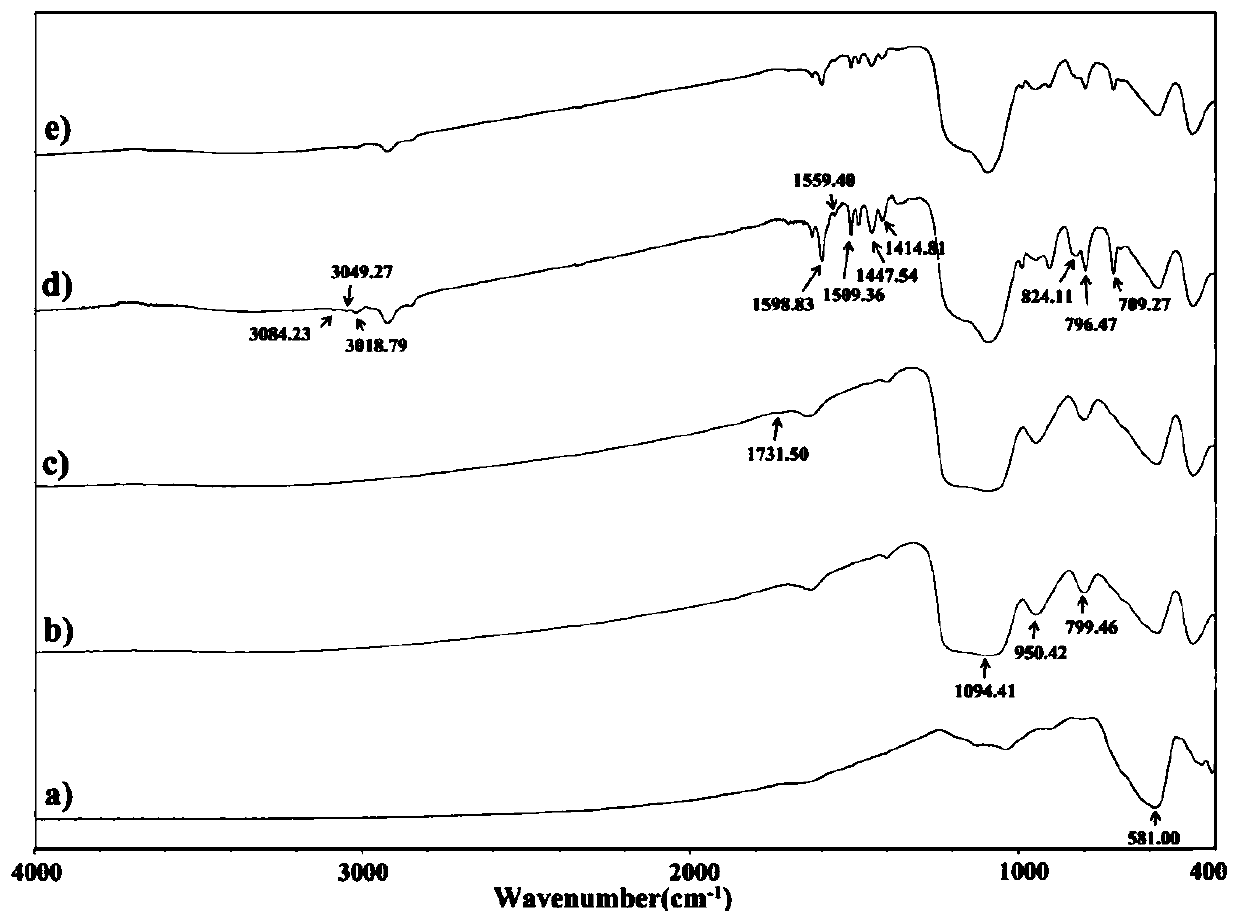

[0023] Preparation of Capsaicin Magnetic Molecularly Imprinted Polymer

[0024] Fe 3 o 4 Silanization: take 0.4g Fe 3 o 4 , add 100mL isopropanol and 8mL distilled water, after ultrasonic dispersion, add 5mL ammonia water and 1mL tetraethyl silicate (TEOS) drop by drop, and mechanically stir at room temperature for 12h. Washed several times with ethanol and deionized water respectively, the prepared Fe 3 o 4 @SiO 2 . Collected with a magnet, dried in vacuum at 45°C for later use.

[0025] Fe 3 o 4 @SiO 2 Surface grafting: In order to make the surface of magnetic nanoparticles have connection sites, the particle surface needs to be modified by grafting. Take 0.5g Fe 3 o 4 @SiO 2 , was added to 50mL of anhydrous toluene, and after ultrasonic dispersion was uniform, 10mL of 3-(methacryloyloxy)propyltrimethoxysilane (MPS) was added dropwise, and N 2 O was removed after 30 min 2 , sealed, and stirred in a 50°C water bath for 24h. Washed several times with toluene ...

Embodiment 2

[0028] Fe 3 o 4 Silanization: Take 0.2g Fe 3 o 4 , add 100mL isopropanol and 8mL distilled water, after ultrasonic dispersion, add 5mL ammonia water and 1mL tetraethyl silicate (TEOS) drop by drop, and mechanically stir at room temperature for 12h. Washed several times with ethanol and deionized water respectively, the prepared Fe 3 o 4 @SiO 2 . Collected with a magnet, dried in vacuum at 45°C for later use.

[0029] Fe 3o 4 @SiO 2 Surface grafting: In order to make the surface of magnetic nanoparticles have connection sites, the particle surface needs to be modified by grafting. Take 0.5g Fe 3 o 4 @SiO 2 , was added to 50mL of anhydrous toluene, and after ultrasonic dispersion was uniform, 10mL of 3-(methacryloyloxy)propyltrimethoxysilane (MPS) was added dropwise, and N 2 O was removed after 30 min 2 , sealed, and stirred in a 50°C water bath for 24h. Washed several times with toluene and ethanol to obtain Fe 3 o 4 @MPS, sucked by magnet, dried in vacuum at...

Embodiment 3

[0032] Fe 3 o 4 Silanization: Take 0.6g Fe 3 o 4 , add 100mL isopropanol and 8mL distilled water, after ultrasonic dispersion, add 5mL ammonia water and 1mL tetraethyl silicate (TEOS) drop by drop, and mechanically stir at room temperature for 12h. Washed several times with ethanol and deionized water respectively, the prepared Fe 3 o 4 @SiO 2 . Collected with a magnet, dried in vacuum at 45°C for later use.

[0033] Fe 3 o 4 @SiO 2 Surface grafting: In order to make the surface of magnetic nanoparticles have connection sites, the particle surface needs to be modified by grafting. Take 0.5g Fe 3 o 4 @SiO 2 , was added to 50mL of anhydrous toluene, and after ultrasonic dispersion was uniform, 10mL of 3-(methacryloyloxy)propyltrimethoxysilane (MPS) was added dropwise, and N 2 O was removed after 30 min 2 , sealed, and stirred in a 50°C water bath for 24h. Washed several times with toluene and ethanol to obtain Fe 3 o 4 @MPS, sucked by magnet, dried in vacuum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com