A kind of food contact water-based wood coating and preparation method thereof

A wood coating, food contact technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as the inability to meet the requirements of material migration and paint film stability, the lack of research on water-based wood coatings, and the limitation of water-based wood coatings. , to achieve the effect of good appearance, excellent stability and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Preparation of vegetable oil modified multi-arm polyol 1:

[0053] 270g castor oil, 200g isophorone diisocyanate and 80g acetone are added in the four-necked round-bottomed flask that nitrogen inlet and outlet are housed through the castor oil of 270g dehydration, stir this mixture at 45 ℃ until NCO reaches 8.04wt%; To 70-75°C, continue to add 120.75g of trimethylolpropane and 65g of acetone, react for 3-4h, the remaining NCO content is measured to be 0.12wt%, stop the reaction, remove the acetone to obtain the vegetable oil modified multi-arm multi-component Alcohol 1.

[0054] Preparation of vegetable oil modified multi-arm polyol 2:

[0055] Add 168g of dehydrated soybean oil and glycerol transesterification reaction product, 160.1g of isophorone diisocyanate and 65g of acetone into a four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and stir at 45°C The mixture until the NCO reaches 9.22wt%; heat up to 70-75°C, continue to add 120.75g tri...

Embodiment 1

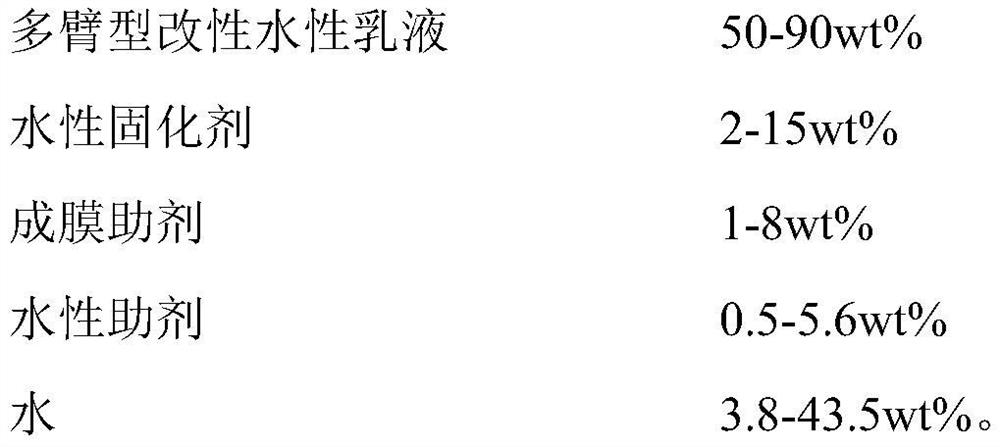

[0064] A kind of food contact water-based wood coating, its composition is as follows, and described specific gravity is weight percentage:

[0065]

Embodiment 2

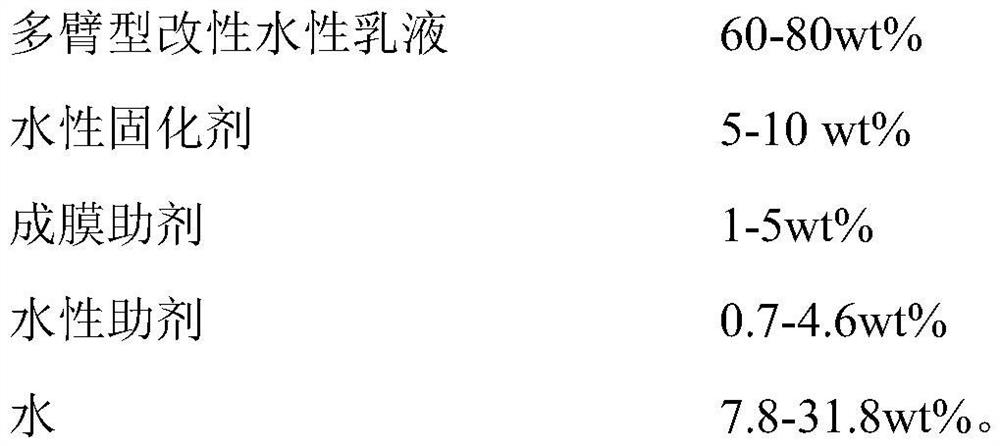

[0067] A kind of food contact water-based wood coating, its composition is as follows, and described specific gravity is weight percentage:

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com