Shock insulation rubber support

A technology of shock-isolation rubber and rubber glue, which is applied in the direction of shockproof, building components, construction, etc., can solve the problems of reducing permanent deformation, molecular chain breakage, poor durability, etc., and achieve good environmental adaptability and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

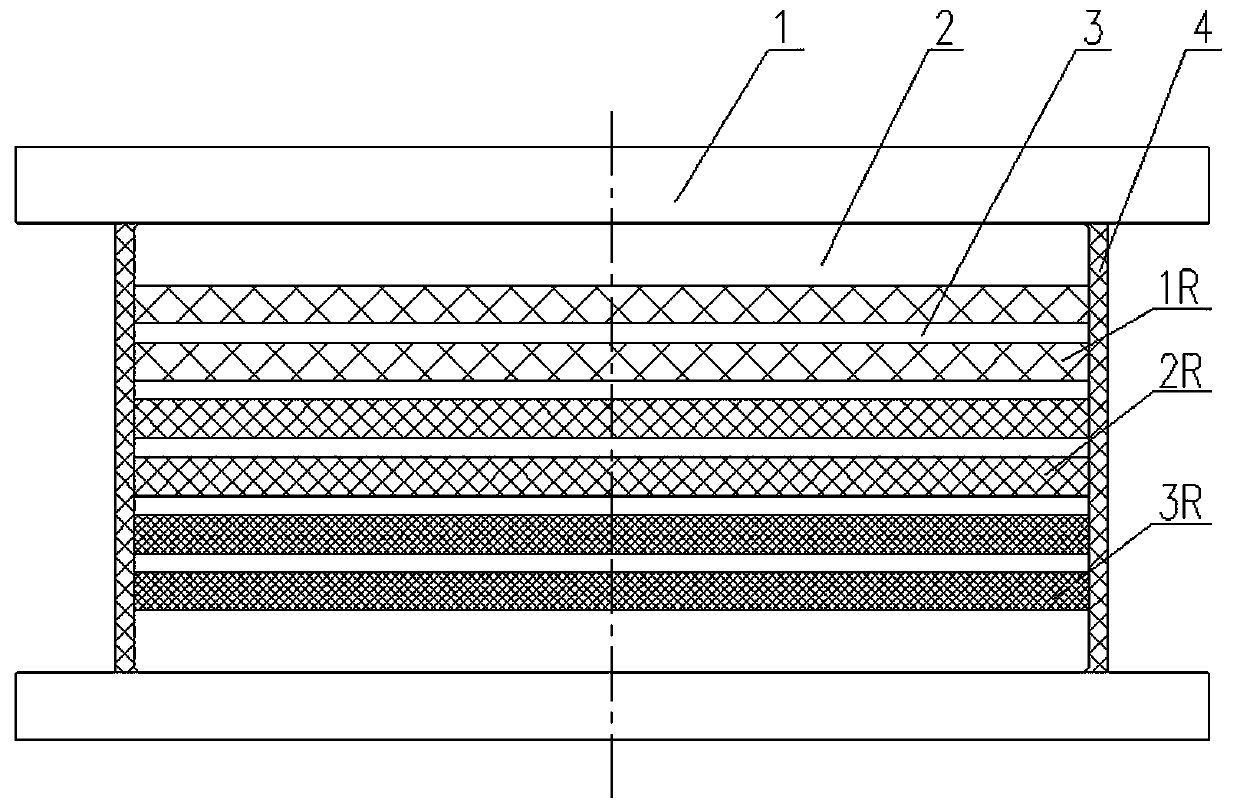

[0033] A shock-isolation rubber bearing of the present invention, such as figure 1 As shown, it is mainly composed of upper and lower support steel plate 1, upper and lower sealing steel plate 2, stiffening steel plate 3, protective adhesive layer 4, first adhesive layer 1R, second adhesive layer 2R, third adhesive Layer 3R composition. The three rubber layers are all nitrile rubber, but the formula is different. The first rubber layer 1R is nitrile rubber with low acrylonitrile content, which has good low temperature performance, flexibility and elasticity; the second rubber layer 2R is high acrylonitrile content Nitrile rubber has good damping performance and high strength; the third rubber layer 3R is nitrile rubber with medium acrylonitrile content, which has good damping performance and moderate performance. The first type of adhesive layer 1R, the second type of adhesive layer 2R and the third type of adhesive layer 3R are vertically arranged sequentially, and the thick...

Embodiment 2

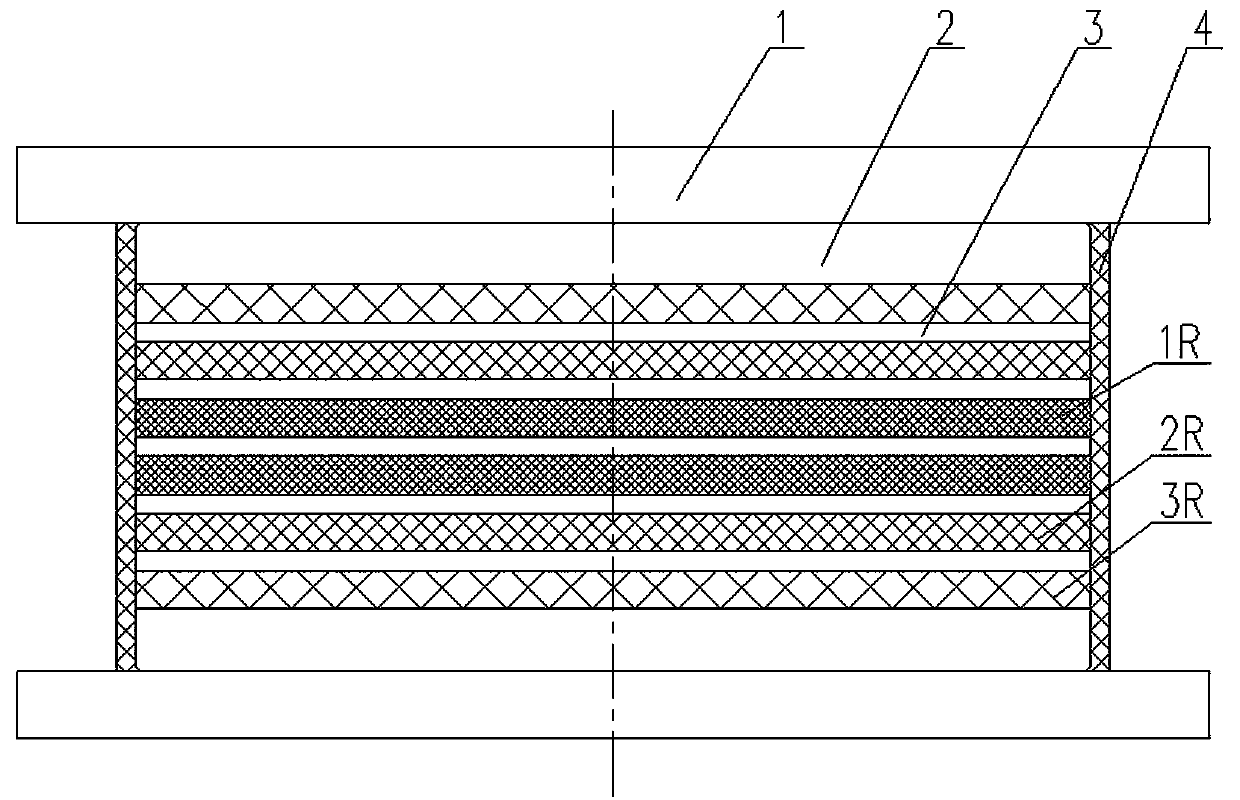

[0035] A shock-isolation rubber bearing of the present invention, such as figure 2As shown, it is mainly composed of upper and lower support steel plate 1, upper and lower sealing steel plate 2, stiffening steel plate 3, protective adhesive layer 4, first adhesive layer 1R, second adhesive layer 2R, third adhesive Layer 3R composition. The first rubber layer 1R is nitrile rubber with medium acrylonitrile content, which has good damping performance; the second rubber layer 2R is nitrile rubber with low acrylonitrile content, which has good low temperature performance, flexibility and elasticity; the third rubber layer Layer 3R is natural rubber with good elasticity and strength. The first type of adhesive layer 1R, the second type of adhesive layer 2R and the third type of adhesive layer 3R are symmetrically arranged, and the thickness of the first type of adhesive layer 3R accounts for 40% of the total thickness of the support adhesive layer. The three adhesive layers have ...

Embodiment 3

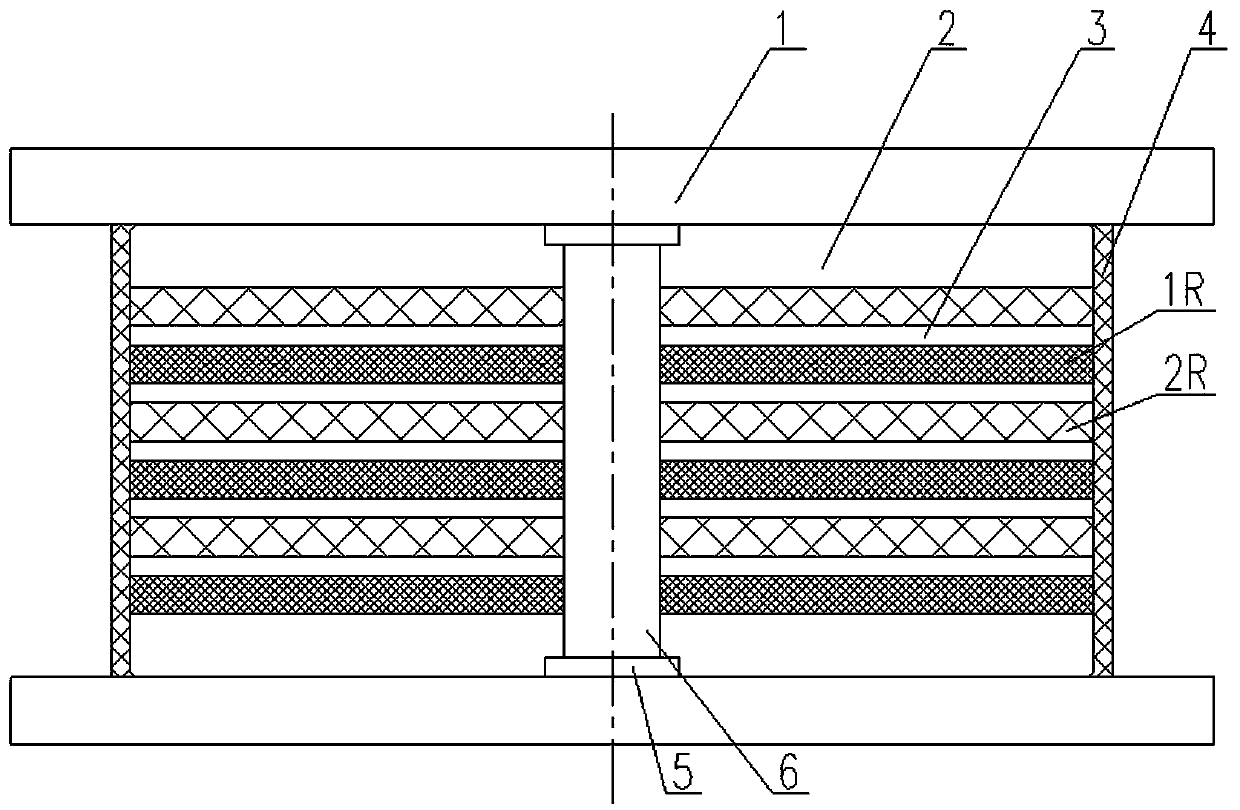

[0037] A shock-isolation rubber bearing of the present invention, such as Figure 4 As shown, it is mainly composed of upper and lower support connecting steel plates 1, upper and lower sealing steel plates 2, stiffening steel plates 3, protective adhesive layer 4, shear key 5, lead core 6, first adhesive layer 1R, second The seed layer is composed of 2R. The two types of glue are the same, but the formula is different. The first type of adhesive layer 1R is natural rubber, reinforced with low-structure carbon black, with high elasticity and good recovery; the second type of adhesive layer 2R is natural rubber, reinforced with high-structure carbon black, with high strength and certain Energy consumption capacity. The first type of adhesive layer 1R and the second type of adhesive layer 2R form a group, the second type of adhesive layer 2R in each group is on the top, the first type of adhesive layer 1R is on the bottom, and multiple groups of adhesive layers are arranged al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com