Anti-seismic composite height adjustable steel support of high-pile wharf

A high-pile wharf and composite technology, applied in the field of building anti-seismic, can solve problems such as unreachable, non-adjustable height, single function, etc., and achieve the effect of reducing deformation and collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

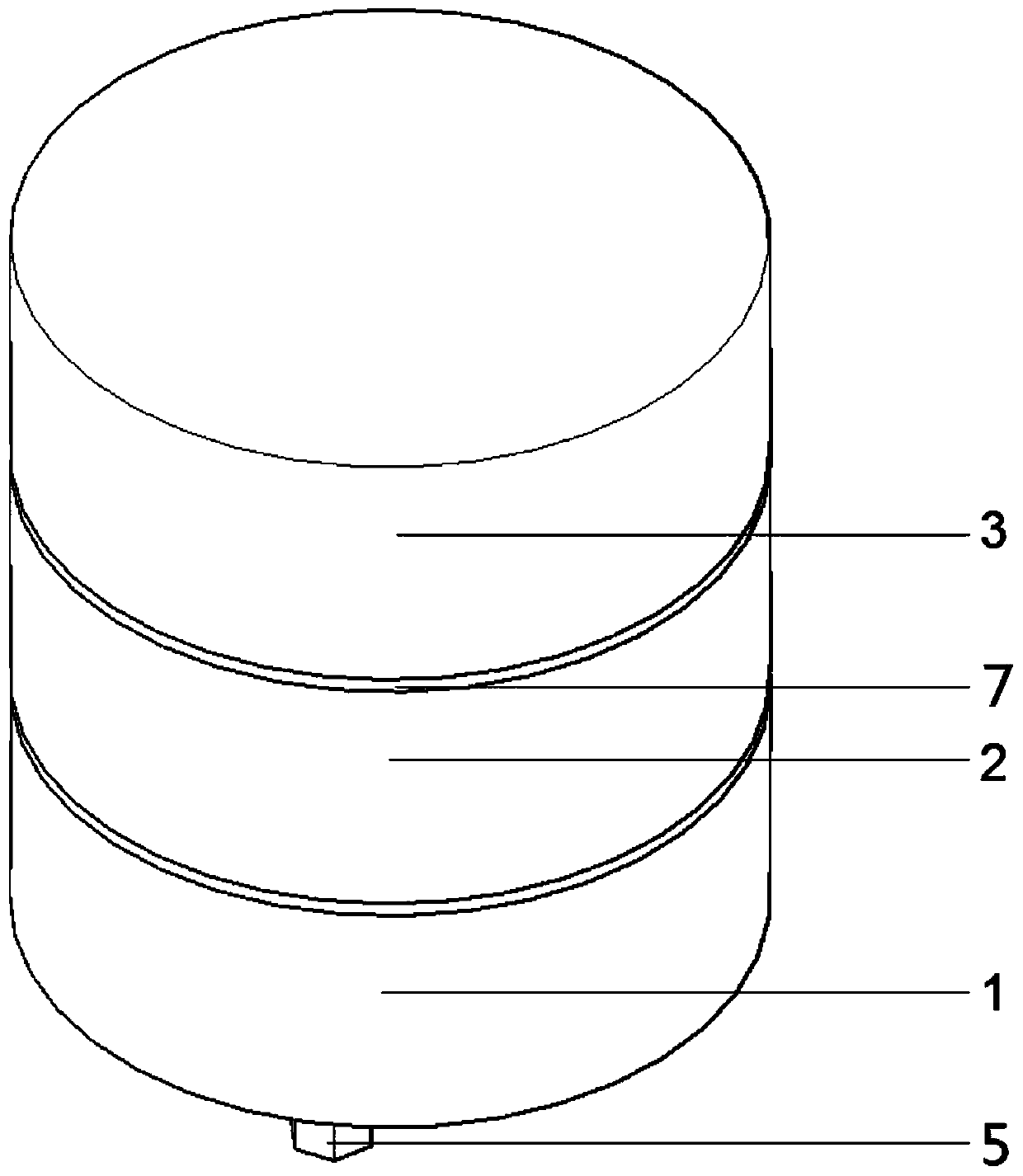

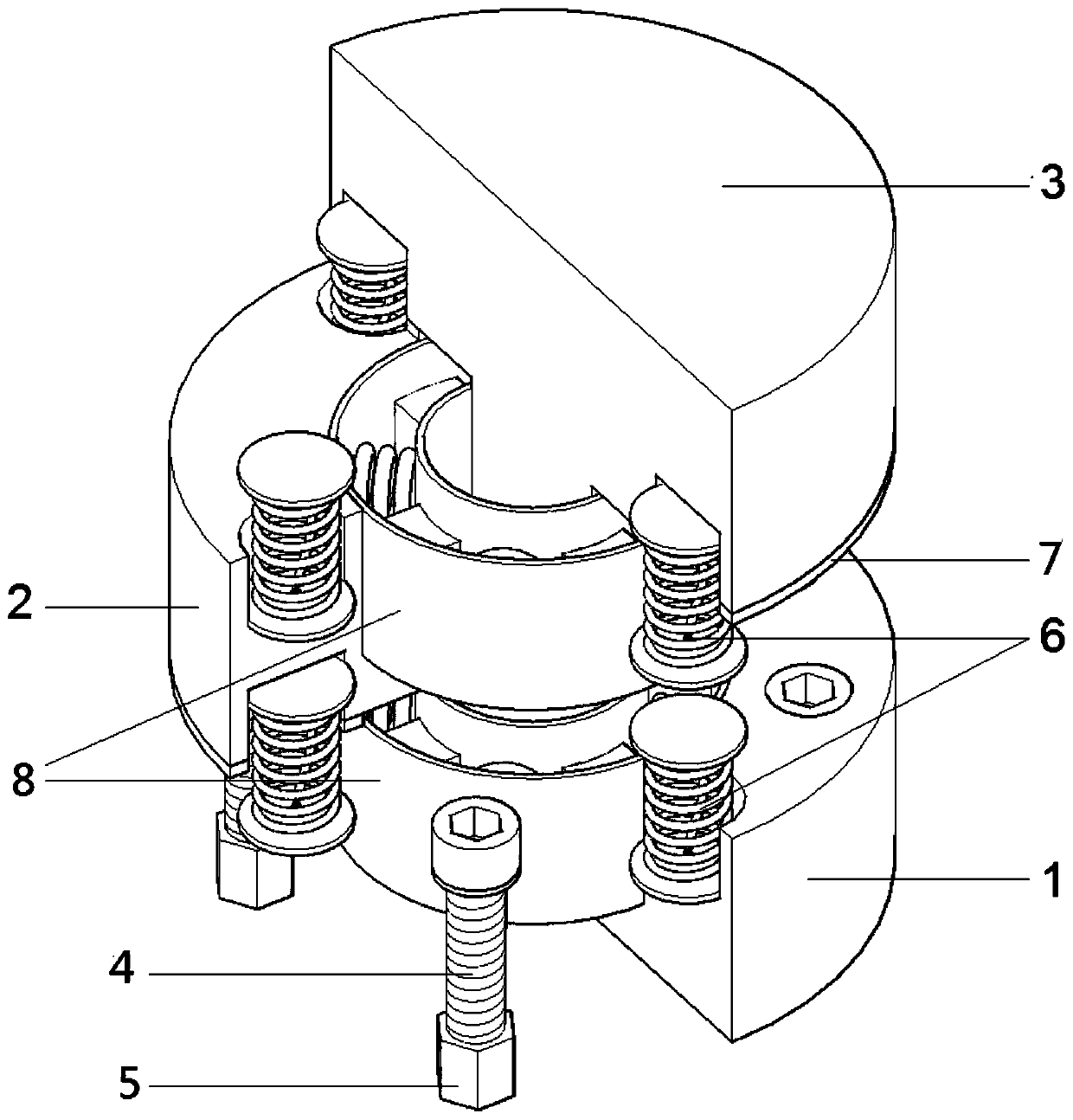

[0024] Specific implementation mode one: as Figure 1 to Figure 9 As shown, the present invention discloses an anti-seismic composite height-adjustable steel support for a high-pile wharf, including a bottom support 1, a standard module support 2, a top support 3, and two fiber-reinforced high-damping elastic rings 7 , two horizontal anti-seismic bearings 8 and a plurality of (eight) vertical pressure springs 6, the top support 3, the standard module support 2 and the bottom support 1 are stacked up and down, in order to avoid the present invention under the action of an earthquake Large displacement occurs, the lower end of the bottom support 1 and the pile cap are fixedly connected by multiple (four) anchor bolts 4, between the top support 3 and the standard module support 2 and between the standard module support 2 and the bottom support 1 are bonded and fixed with fiber-reinforced high-damping elastic rings 7, and are elastically connected through horizontal anti-seismic b...

specific Embodiment approach 2

[0025] Specific implementation mode two: as figure 1 , 2 As shown, this embodiment is a further description of specific embodiment 1. The bottom support 1, the standard module support 2 and the top support 3 are all cylindrical steel supports and the diameters of the three are the same, and the steel material rigidity Large, can resist the load transmitted by the structure.

specific Embodiment approach 3

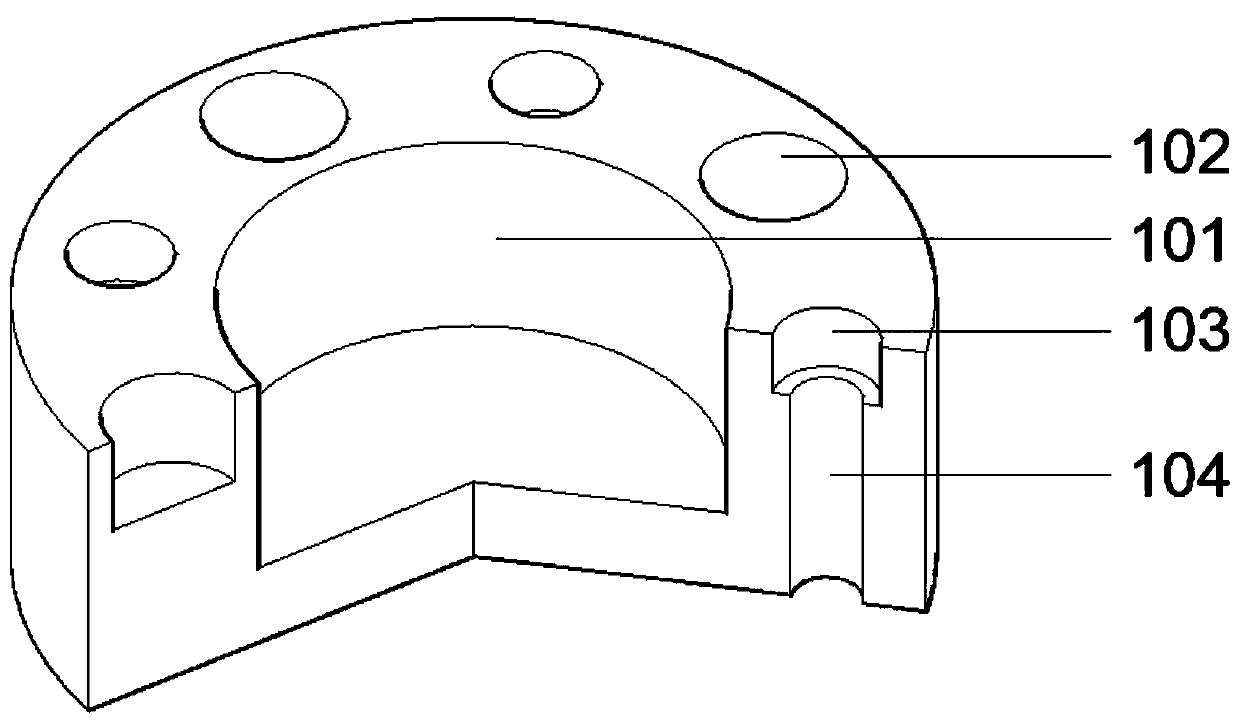

[0026] Specific implementation mode three: as Figure 2-6 As shown, this embodiment is a further description of the second specific embodiment. The middle part of the upper surface of the bottom support 1 and the standard module support 2 is provided with a cylindrical groove 101, and the bottom support 1 and the standard module support The edge of the upper surface of the seat 2 is provided with a plurality of (four) vertical pressure spring lower clamping grooves 102 along the circumferential direction, and the edge of the upper surface of the bottom support 1 is also provided with a plurality of (four) nut clamping grooves along the circumferential direction 103, the multiple (four) vertical bearing spring lower slots 102 and multiple (four) nut slots 103 of the bottom support 1 are alternately arranged one by one, each of the nut slots 103 The bottom surface of the groove all runs through the bottom surface of the bottom support 1 and is provided with a bolt through hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com