Gas injection oil production process in double-layer oil pipe

A double-layer tubing and process technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of frequent string tripping and casing corrosion, and achieve the effect of saving operating costs and reducing leak detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

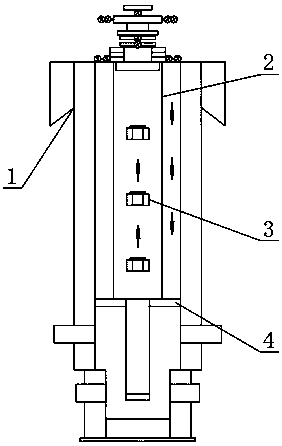

Image

Examples

Embodiment

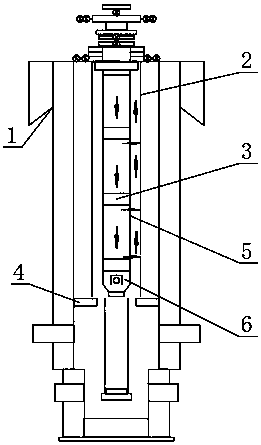

[0031] see figure 2 , the present invention provides a technical solution: a gas injection and oil recovery process in a double-layer oil pipe, the gas lift process is as follows:

[0032] Step 1: Lower the small oil pipe 5 into the main oil pipe 2, and install the gas lift valve 3 on the small oil pipe 5;

[0033] Step 2: Inject nitrogen or natural gas into the small oil pipe 5;

[0034] Step 3: The oil is discharged from the annular space of the small oil pipe 5 and the main oil pipe 2, and the gas lift production is carried out.

[0035] In this embodiment, preferably, the small oil pipe 5 is also provided with a POP check valve 6, and the POP check valve 6 and the small oil pipe 5 are connected by screwing, which helps to realize the POP check valve 6 and the small oil pipe 5. The installation and disassembly of the POP check valve 6 is set to avoid oil backflow.

[0036] In this embodiment, preferably, a packer 4 for sealing off the annular space is also included.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com