Multiphase medium fracturing device for fluid testing and testing system

A medium and fluid technology, which is applied in the field of multiphase medium fracturing devices and test systems, can solve the problems of wall damage, long displacement distance, and difficulty of cores in the diversion chamber, and achieves strong practicability, application prospects, and cost of construction. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention more clear and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

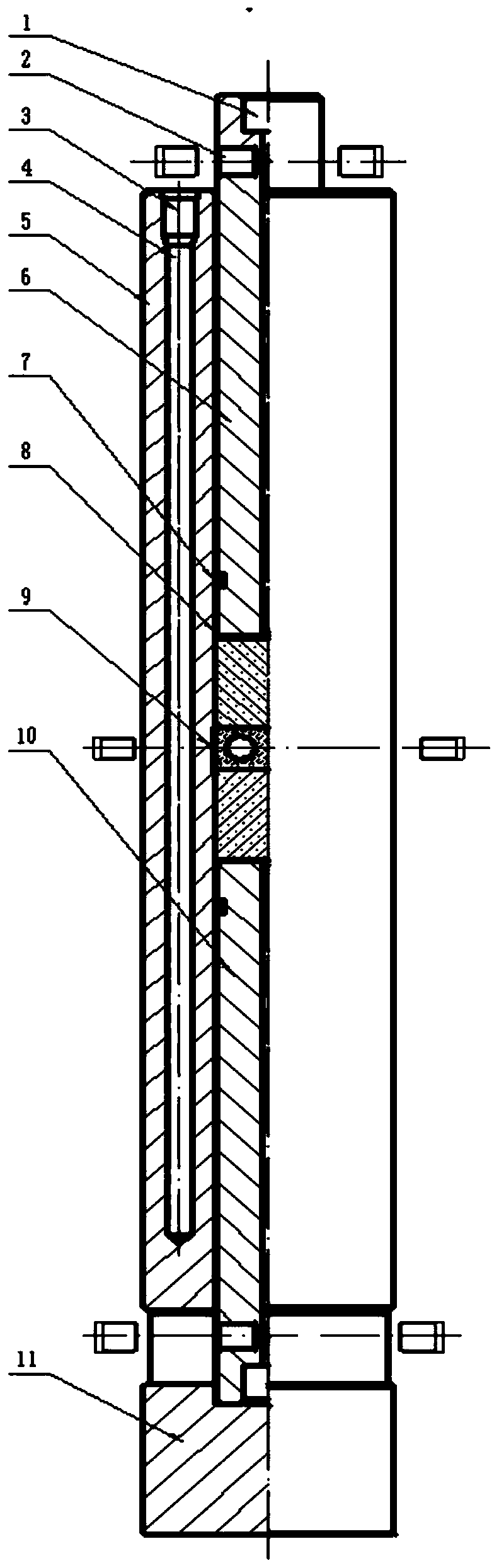

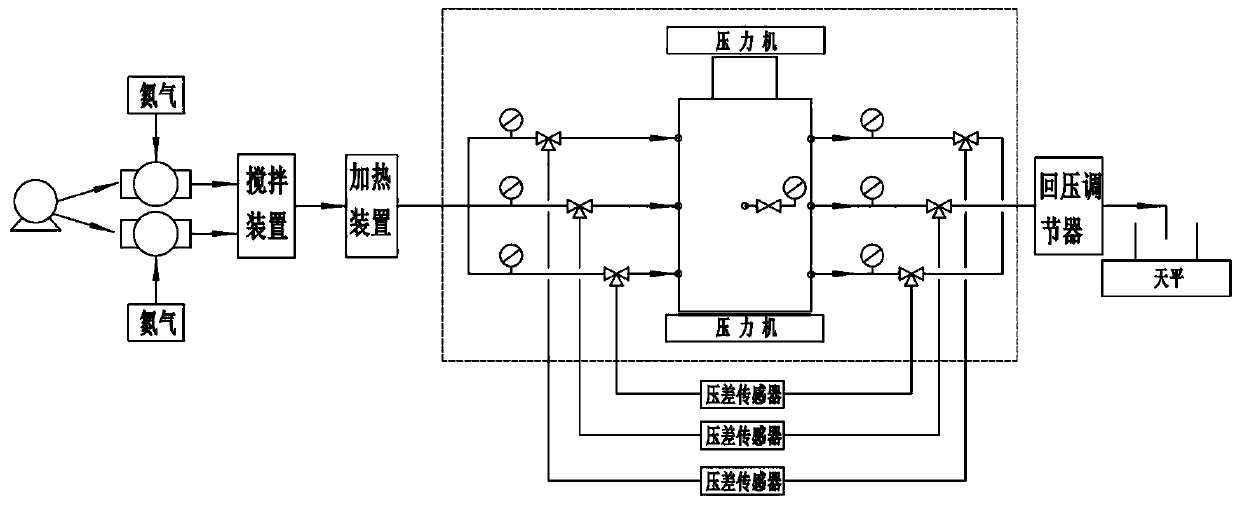

[0025] In view of the high cost of the diversion experimental device in the existing oilfield fracturing test and the inability to meet the high viscosity and acid-base fluid core displacement experiments, etc., in the embodiments of the present invention, see figure 1 As shown, a multiphase medium fracturing device for fluid testing is provided, comprising: a nickel-based alloy base; and a nickel-based alloy main body arranged on the base, and a working channel for fixing fracturing components is provided in the main body; The fracturing assembly includes an upper piston rod connected to the press and a lower piston rod set on the base to cooperate with the upper piston rod, and a fracturing chamber for placing materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com