Method for rapidly predicting dry density, out-of-kettle moisture content and water absorption rate of aerated concrete

A technology of aerated concrete and water absorption, applied in the field of building materials, can solve the problems of high heating temperature, long processing time, damage to the internal structure of aerated concrete, etc., and achieve the effect of simple test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

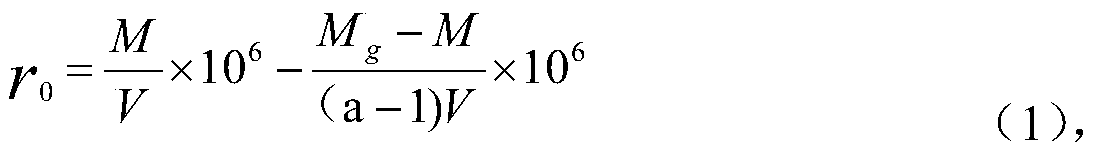

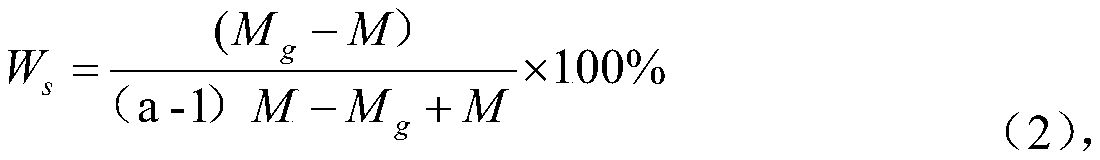

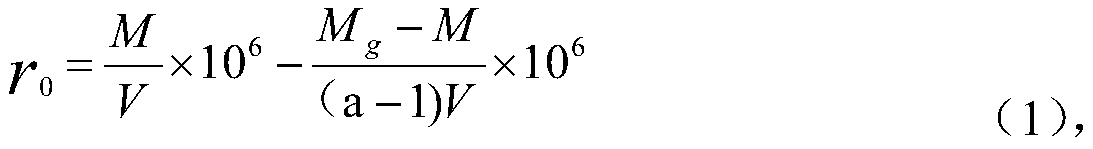

Method used

Image

Examples

Embodiment 1

[0034] A certain batch of air-entrained concrete is measured according to the method for rapidly predicting the dry density of the air-entrained concrete, the moisture content and the water absorption rate after leaving the kettle provided by the present invention.

[0035] The measurement results are as follows:

[0036] The calculation results when a=1.8 are shown in the table below:

[0037]

[0038] The calculation results when a=2.0 are shown in the table below:

[0039]

[0040] The calculation results when a=2.2 are shown in the table below:

[0041]

[0042] Based on the above data, the dry density of the air-entrained concrete, the water content and water absorption after leaving the kettle are shown in the following table:

[0043]

[0044] According to GB / T11969-2008 "Autoclaved Air-entrained Concrete Performance Test Method", the dry density, water content and water absorption of the air-entrained concrete specimens were measured.

[0045] The measur...

Embodiment 2

[0051] Another batch of air-entrained concrete was measured according to the method for quickly predicting the dry density of air-entrained concrete, water content and water absorption rate after exiting the kettle, and the measurement results are as follows:

[0052] The calculation results when a=1.8 are shown in the table below:

[0053]

[0054] The calculation results when a=2.0 are shown in the table below:

[0055]

[0056] The calculation results when a=2.2 are shown in the table below:

[0057]

[0058] Based on the above data, the dry density of the air-entrained concrete, the water content and water absorption after leaving the kettle are shown in the following table:

[0059]

[0060] According to GB / T11969-2008 "Autoclaved Air-entrained Concrete Performance Test Method", the dry density, water content and water absorption of the air-entrained concrete specimens were measured. The measurement results are shown in the table below:

[0061]

[0062] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com