Method for testing the peel strength of solid electrolyte membrane

A solid electrolyte membrane and peel strength technology, applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problems of low data accuracy, poor overall application effect, complicated operation, etc. Peeling effect, effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

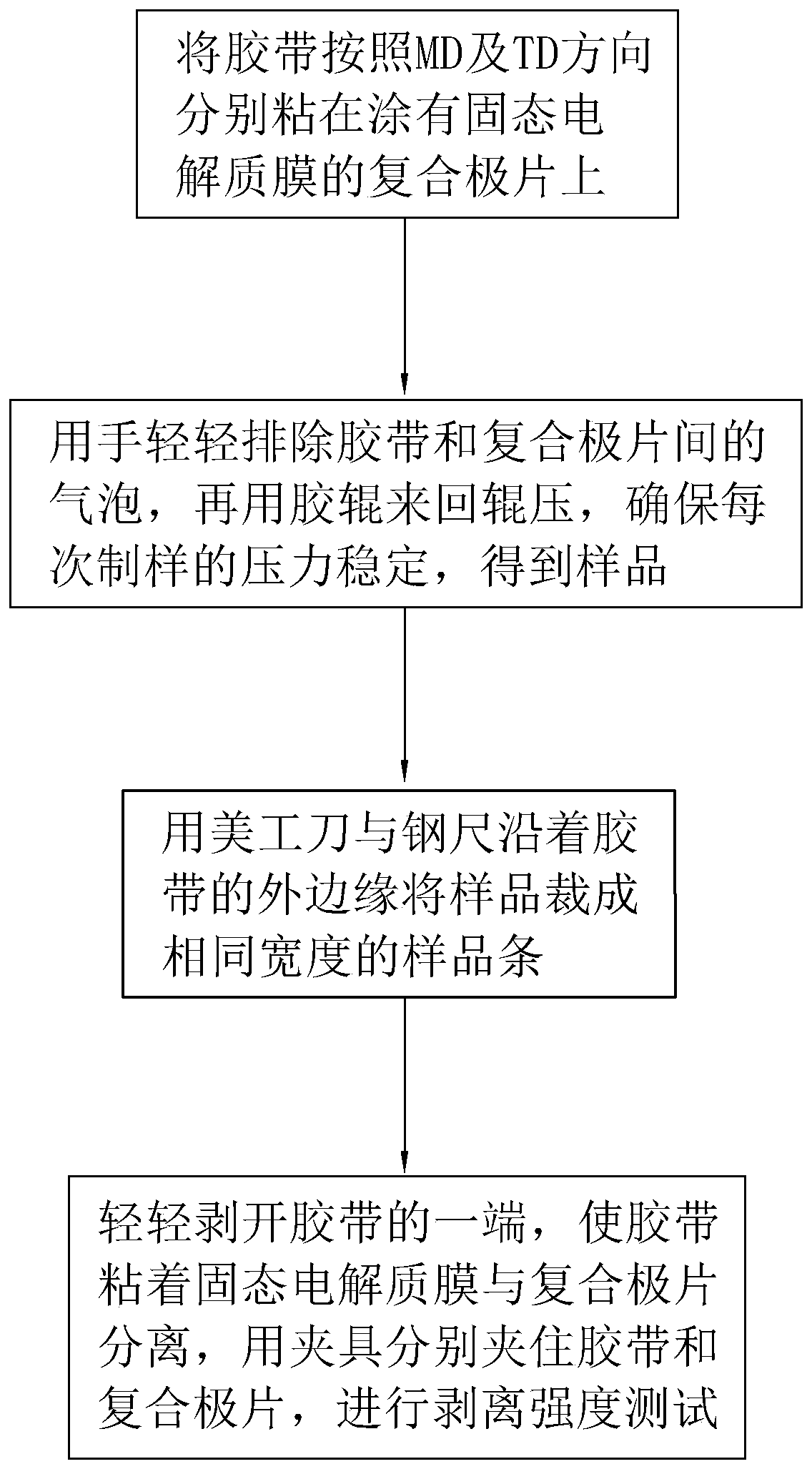

[0033] Embodiment 1: A method for testing the peel strength of a solid electrolyte membrane, comprising the following steps:

[0034] Step 1: Stick 19mm wide 3M adhesive tape on the composite pole piece coated with solid electrolyte membrane according to the MD and TD directions;

[0035] Step 2: Gently remove the air bubbles between the tape and the composite pole piece by hand, and then use a 2.1kg rubber roller to roll back and forth 9 times to ensure that the pressure of each sample preparation is stable and the sample is obtained;

[0036] Step 3, use a utility knife and a steel ruler to cut the sample into sample strips of the same width along the outer edge of the tape;

[0037] Step 4. Gently peel off one end of the tape, and the length of the tape is 4mm, so that the solid electrolyte membrane adhered to the tape is separated from the composite pole piece, and the tape and the composite pole piece are respectively clamped with a clamp, and the peel strength test is pe...

Embodiment 2

[0038] Embodiment 2: A method for testing the peel strength of a solid electrolyte membrane. The difference from Example 1 is that in step 1, a 16mm wide 3M adhesive tape is adhered to the composite pole piece coated with a solid electrolyte membrane according to the MD and TD directions. ;

[0039] Step 2: Gently remove the air bubbles between the tape and the composite pole piece by hand, and then use a 1.8kg rubber roller to roll back and forth 8 times to ensure that the pressure of each sample preparation is stable and the sample is obtained;

[0040] Step 3, use a utility knife and a steel ruler to cut the sample into sample strips of the same width along the outer edge of the tape;

[0041] Step 4. Gently peel off one end of the tape, and the length of the tape is 3mm, so that the solid electrolyte membrane adhered to the tape is separated from the composite pole piece, and the tape and the composite pole piece are respectively clamped with a clamp, and the peel strength...

Embodiment 3

[0042] Embodiment 3: A method for testing the peel strength of a solid electrolyte membrane. The difference from Example 1 is that in step 1, a 22mm wide 3M adhesive tape is adhered to the composite pole piece coated with a solid electrolyte membrane according to the MD and TD directions. ;

[0043] Step 2: Gently remove the air bubbles between the tape and the composite pole piece by hand, and then use a 2.4kg rubber roller to roll back and forth 10 times to ensure that the pressure of each sample preparation is stable and the sample is obtained;

[0044] Step 3, use a utility knife and a steel ruler to cut the sample into sample strips of the same width along the outer edge of the tape;

[0045] Step 4. Gently peel off one end of the tape, and the length of the tape is 5mm, so that the solid electrolyte membrane adhered to the tape is separated from the composite pole piece, and the tape and the composite pole piece are respectively clamped with a clamp, and the peel strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com