Composite film, preparation method and application thereof and backlight module

A technology of composite film and quantum dot glue layer, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of multi-layer assembly of light loss, influence of luminous effect, and complicated operation process, so as to improve light scattering performance and reduce diaphragm Effect of scratching and improving the brightness of the light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a kind of preparation method of composite membrane, comprises the following steps:

[0045] S101: forming a diffusion layer, or forming a reflection layer;

[0046] Existing methods can be used to prepare the diffusion layer and the reflective layer, which are not particularly limited here.

[0047] S102: forming a quantum dot glue layer on the diffusion layer, or forming a quantum dot glue layer on the reflective layer;

[0048] It is understandable that the diffusion layer can be formed first, the quantum dot layer can be formed on the diffusion layer, and then the reflective layer can be formed, or it can be reversed, the reflective layer can be formed first, the quantum dot layer can be formed on the reflective layer, and then the diffusion layer can be formed. layer, should be understood as within the protection scope of the present invention.

[0049] Further, step S102 includes the following steps:

[0050] S1021: dissolving...

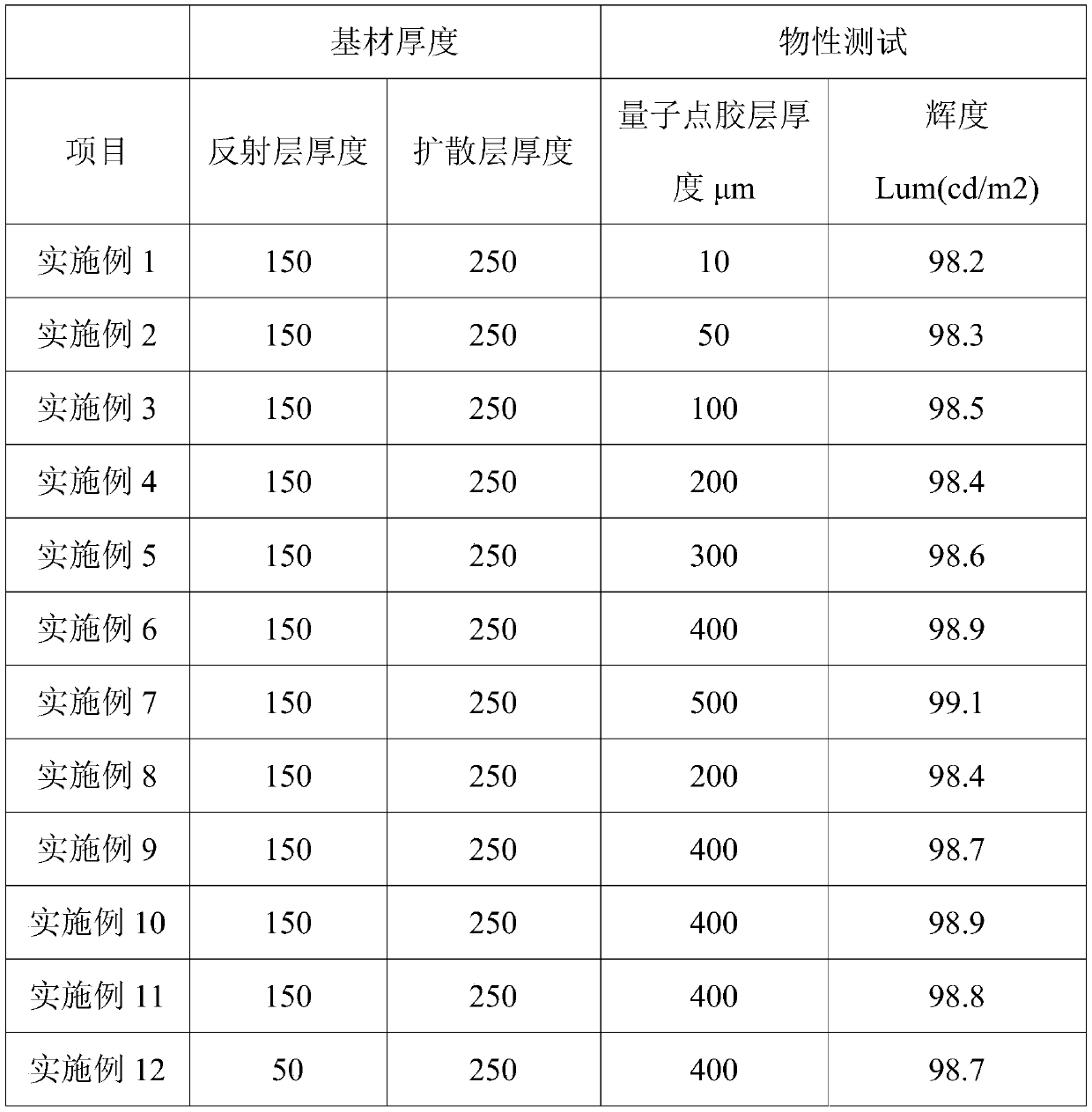

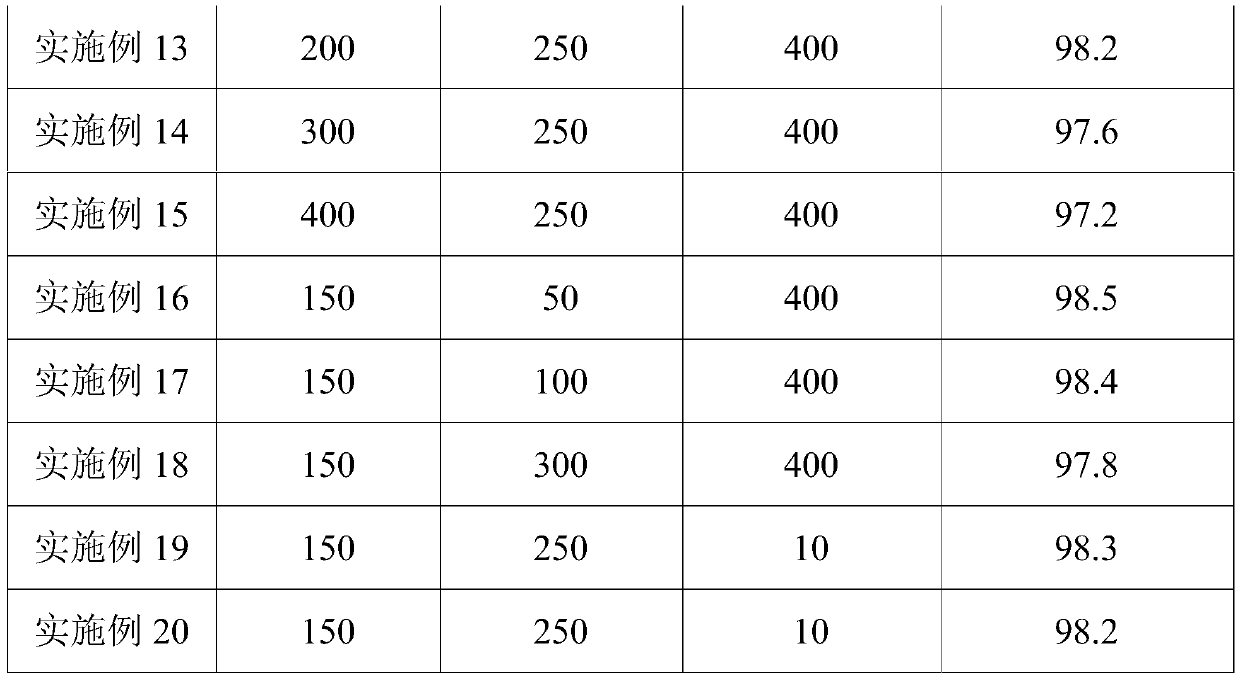

Embodiment 1

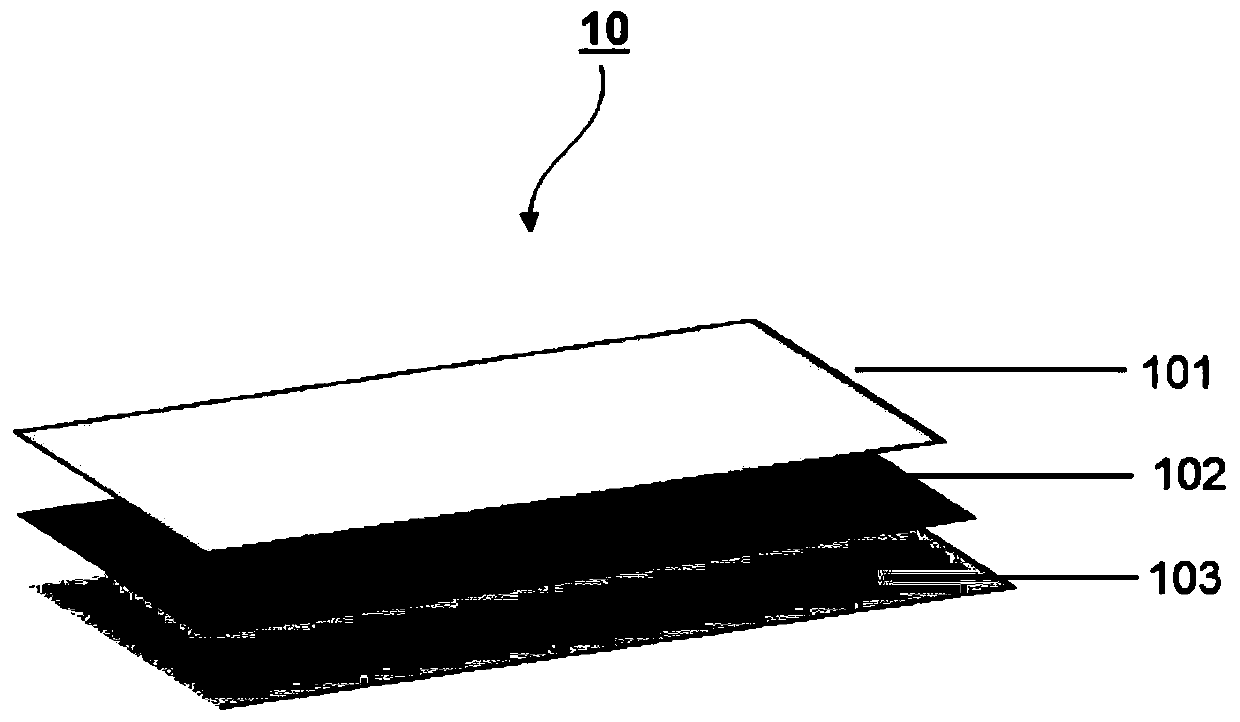

[0065] The composite film structure of Example 1 is a reflection layer, a quantum dot adhesive layer and a diffusion layer stacked in sequence, and the preparation method is as follows:

[0066] (1) Provide a reflective base material with a thickness of 150 μm as a reflective layer (Ningning Longyang Technology Co., Ltd., DJX250);

[0067] (2) Form a quantum dot adhesive layer on the reflective layer, specifically: dissolve 1 part of cyanoacrylate adhesive and 0.1 part of cadmium disulfide in 50 parts of toluene solution, mix evenly, and form a coating cloth liquid. Apply it on the reflective layer by coating, and dry it in a drying oven at 110°C for 2 minutes.

[0068] (3) Using a 250 μm diffusion substrate as a diffusion layer, the above-mentioned quantum dot adhesive layer was composited with a 250 μm thick diffusion layer (Ningbo Longyang Science and Technology Co., Ltd., HD250D) and cooled to room temperature to obtain a high-brightness composite film.

Embodiment 2

[0070] It is basically the same as Example 1, except that the adhesive is 4 parts, and the quantum dot material is 0.2 parts, so that the composite film of Example 2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com