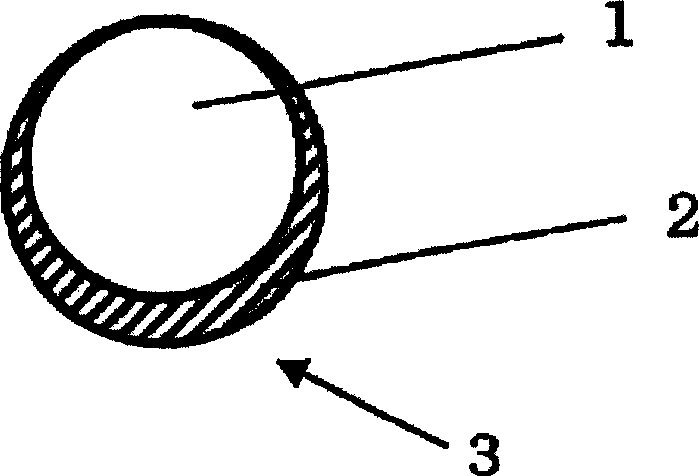

Polymer particle coated with silica, method for producing the same and use of the same

A technology for polymer particles and coating, applied in the fields of polymer particles coated with silica gel and their preparation and use, can solve problems such as the limitation of available substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] 5 grams of magnesium pyrophosphate obtained by metathesis are mixed with 200 grams of water as a suspension stabilizer to obtain a dispersion medium, and the dispersion medium is added to a 500 milliliter separable flask, and 0.04 grams of sodium lauryl sulfate is used as a surfactant and 0.02 gram of sodium nitrate are dissolved in the dispersion medium as a polymerization inhibitor.

[0173] 70 g of methyl methacrylate as a monofunctional polymerizable vinyl monomer, 30 g of MKCsilicate MS57 (manufactured by Mitsubishi Chemical Co., Ltd.: average molecular weight 1300-1500, R in the aforementioned structure is methyl, n average 15-18) as a polyalkoxysiloxane oligomer and 0.25 g of 2,2'-azobis(2,4-dimethylvaleronitrile) as a polymerization initiator were uniformly dissolved to prepare a monomer composition .

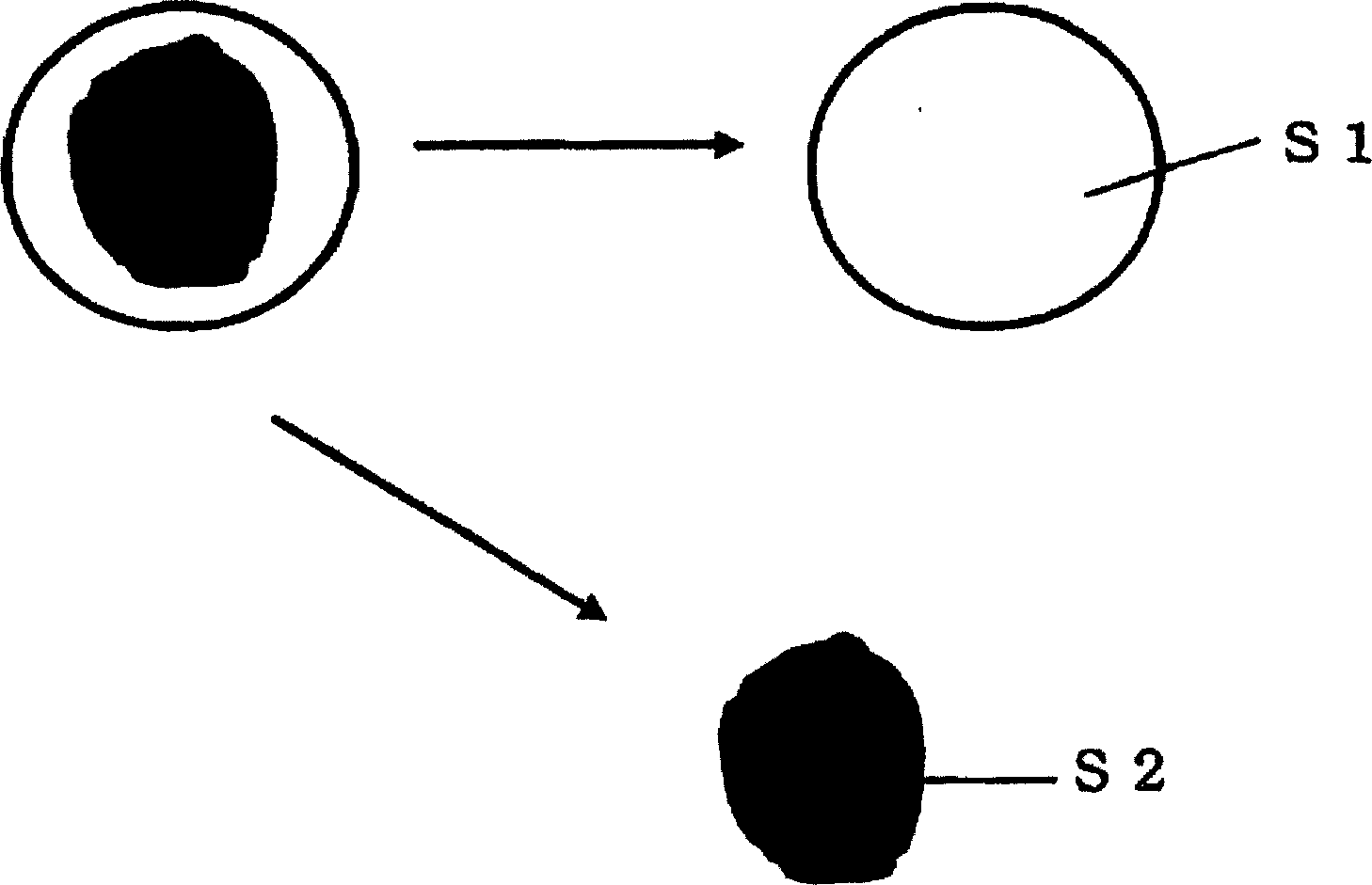

[0174] The resulting monomer composition was added to the above dispersion medium, and stirred at 8000 rpm for 10 seconds with a homomixer (ULTRATURRAX T-25, ma...

Embodiment 2

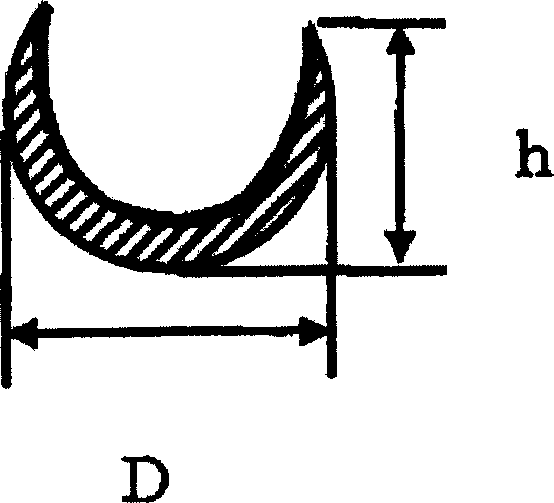

[0177] According to the method same as embodiment 1, obtain the polymer particle that the surface of the polymer particle is exposed and be coated with silica gel, difference is that the amount of methyl methacrylate is changed into 30 grams, the amount of MKC silicate MS57 is changed into 70 grams, The amount of 2,2'-azobis(2,4-dimethylvaleronitrile) was changed to 0.15 g. The obtained silica gel-coated polymer particles had a volume average particle diameter of 116.3 µm, and the glass transition temperature of the polymer particles obtained from a polymerizable vinyl monomer was 105°C. The specular reflectance, aperture ratio, h / D and refractive index of the particles are shown in Table 1.

Embodiment 3

[0179] According to the same method as in Example 1, polymer particles coated with silica gel with the surface of the polymer particles exposed were obtained, except that MKC silicate MS 51 (manufactured by Mitsubishi Chemical Co., Ltd.: average molecular weight 500-700, aforementioned R in the structure is a methyl group, and the average n is 5-10) as a polyalkoxysiloxane oligomer. The obtained silica gel-coated polymer particles had a volume average particle diameter of 6.4 µm, and the glass transition temperature of the polymer particles obtained from a polymerizable vinyl monomer was 105°C. The specular reflectance, aperture ratio, h / D and refractive index of the particles are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com