Three-dimensional magnetic flux leakage detection defect reconstruction method based on generative adversarial network

A magnetic flux leakage detection and defect technology, applied in the fields of material magnetic variables, image data processing, instruments, etc., can solve the problems of long calculation time, low reconstruction efficiency, low reconstruction accuracy, etc., to improve the reconstruction calculation speed, reduce The effect of reconstruction cost and reconstruction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

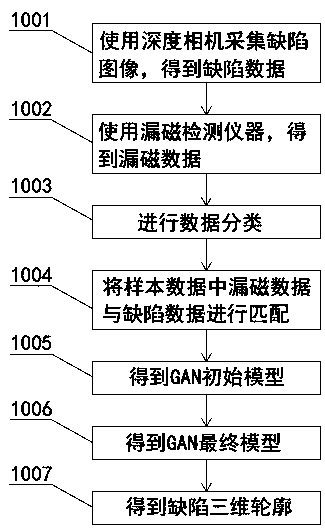

[0050] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0051] Such as figure 1 As shown, a three-dimensional magnetic flux leakage detection defect reconstruction method based on generative confrontation network includes the following steps:

[0052] Step 1001, using a depth camera to collect defect images to obtain defect data;

[0053] Select the defect imaging area on the bottom plate, and use the depth camera to capture the imaging area, where the bottom plate defects include artificial defects and corrosion defects. The material of the artificial defect and the corrosion defect are the same, and the thickness of the bottom plate is the same. Among them, the artificial defect satisfies the single change of the three variables of width, length and depth. [2mm, 10mm], the thickness of the bottom plate is 12mm, the material is Q245, and the artificial defect dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com