Flame-retardant microsphere electrolyte and preparation method thereof

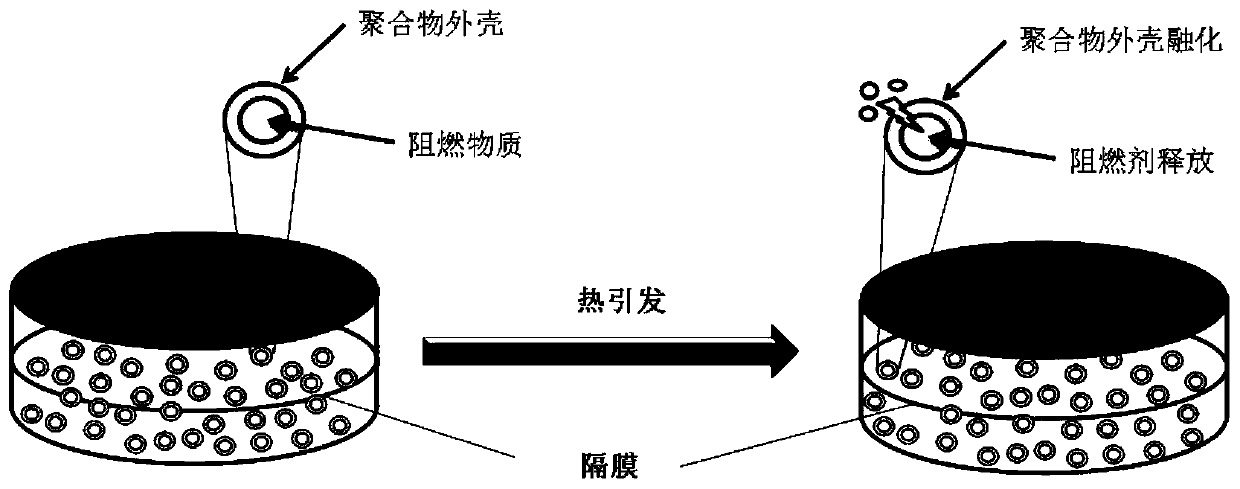

An electrolyte and microsphere technology, which is applied in the field of flame-retardant microsphere electrolyte and its preparation, can solve the problems of loss of initial capacity and poor cycle performance of standard electrolytes, and achieve the goal of preventing battery combustion, avoiding adverse effects, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

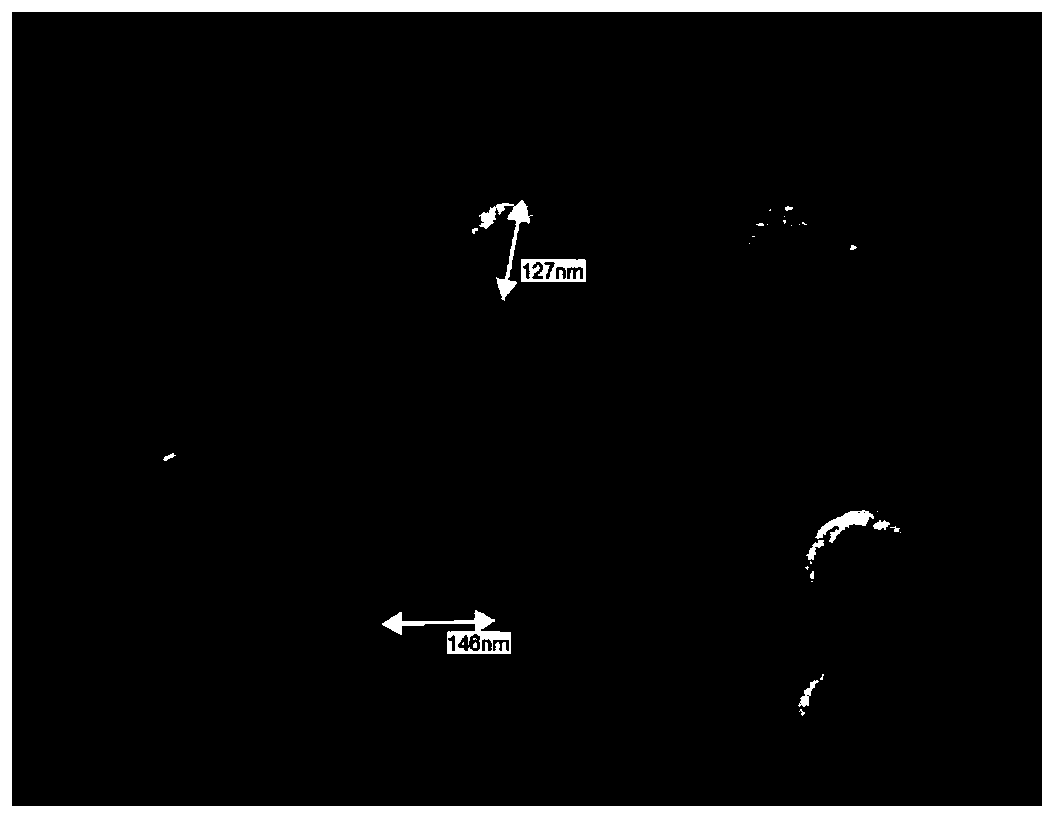

[0038] (1) Preparation of TPP@PVDF-HFP core-shell microspheres: TPP and PVDF-HFP were mixed and dissolved at a ratio of 1:1 (w / w) in a mixed solution of dimethylacetamide and acetone (3:7, w / w), the concentration after dissolution was 16 wt%. Afterwards, a high voltage of 9kV, an injection speed of 1.0ml / h and a receiving distance of 25cm were used to obtain 50-100nm size core-shell structure microspheres TPP@PVDF-HFP by electrostatic spraying technology.

[0039] (2) Preparation of TPP@PVDF-HFP flame retardant electrolyte: firstly dissolve 2% wt TPP@PVDF-HFP in 1.0mol / L LiPF 6 / EC+DMC (1:1wt%) ordinary electrolyte, add 0.2%wt dispersant MF to make flame retardant electrolyte.

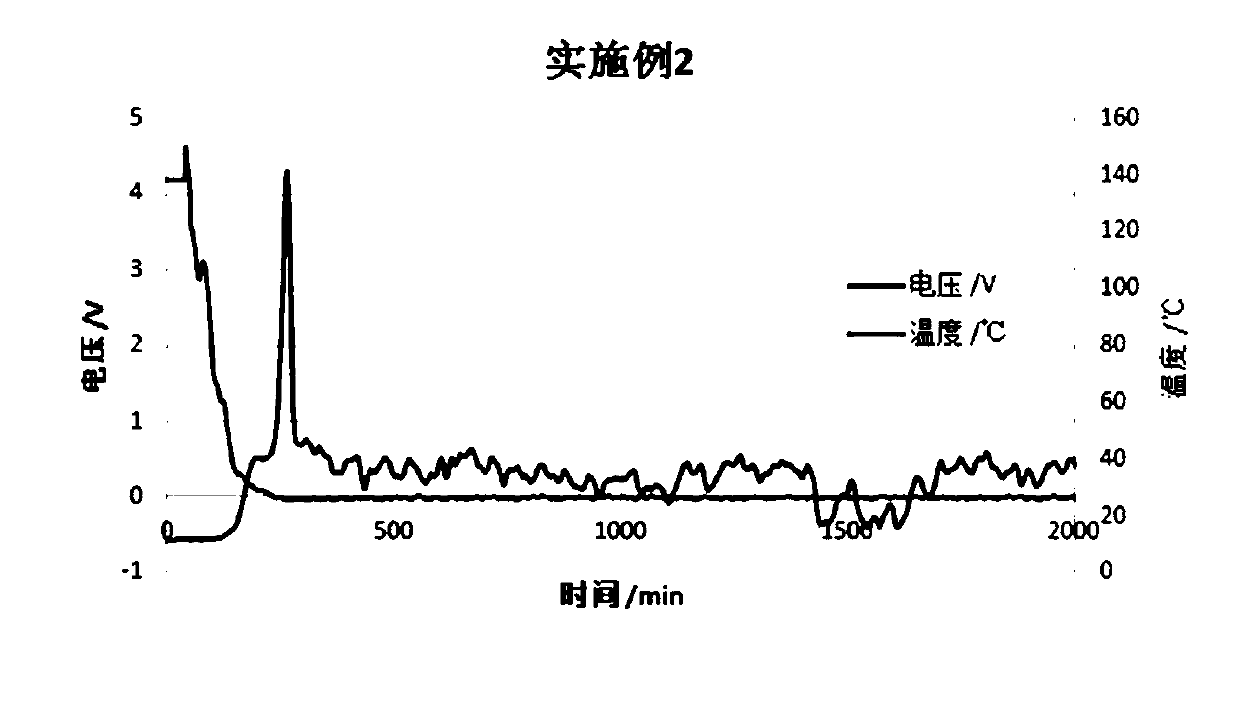

Embodiment 2

[0041] Preparation of TPP@PVDF-HFP core-shell microspheres: TPP and PVDF-HFP were mixed and dissolved in a mixed solution of dimethylacetamide and acetone (4:6w / w) at a ratio of 3:2 (w / w), The concentration after dissolution was 20 wt%. After that, 150-200nm core-shell structure microspheres TPP@PVDF-HFP were obtained by electrostatic spraying technology with a high voltage of 12kV, an injection speed of 2.0ml / h and a receiving distance of 20cm.

[0042] Preparation of TPP@PVDF-HFP flame retardant electrolyte: Firstly, 4% wt TPP@PVDF-HFP was dissolved in 1.2mol / LLiPF 6 / EC+DEC (1.2: 1wt%) ordinary electrolyte, add 0.4%wt dispersant MF to make a flame retardant electrolyte.

Embodiment 3

[0044] Preparation of TPP@PVDF-HFP core-shell microspheres: TPP and PVDF-HFP were mixed and dissolved in a mixed solution of dimethylacetamide and acetone (5:5) at a ratio of 2:3, and the dissolved concentration was 25wt% . After that, 250-300nm core-shell structure microspheres TPP@PVDF-HFP were obtained by electrostatic spraying technology with a high voltage of 16kV, an injection speed of 4.0ml / h and a receiving distance of 15cm.

[0045] Preparation of TPP@PVDF-HFP flame retardant electrolyte: Firstly, 5%wt TPP@PVDF-HFP was dissolved in 1.1mol / L LiPF 6 / EC+DMC+DEC (1:1:1wt%) ordinary electrolyte, add 0.5% wt5040 dispersant to make flame retardant electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com