Strong coupling frequency selective surface structure insensitive to all angles of incident electromagnetic waves

A frequency selective surface and electromagnetic wave technology, applied in the field of metasurfaces, can solve the problems of FSS operating frequency deviation, system performance degradation, unfavorable engineering realization, etc., and achieve the effect of transmission zero point stability, overall weight reduction, and good angular stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

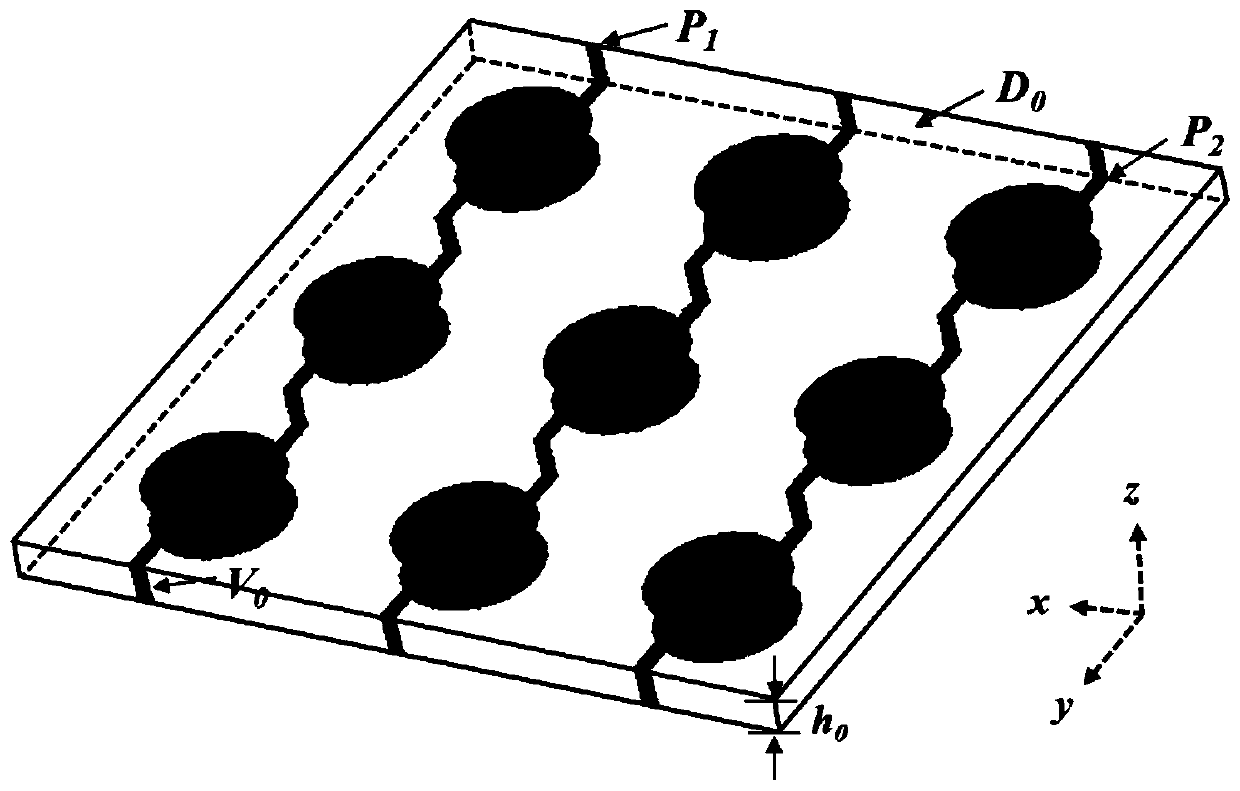

[0046] Such as figure 1 As shown, the implemented frequency selective surface structure includes a plurality of closely arranged periodic unit structures, and each periodic unit structure is mainly composed of a dielectric layer, two metal layers and metal vias connecting the two metal layers, wherein the two The first metal layer is attached to the two surfaces of the dielectric layer respectively.

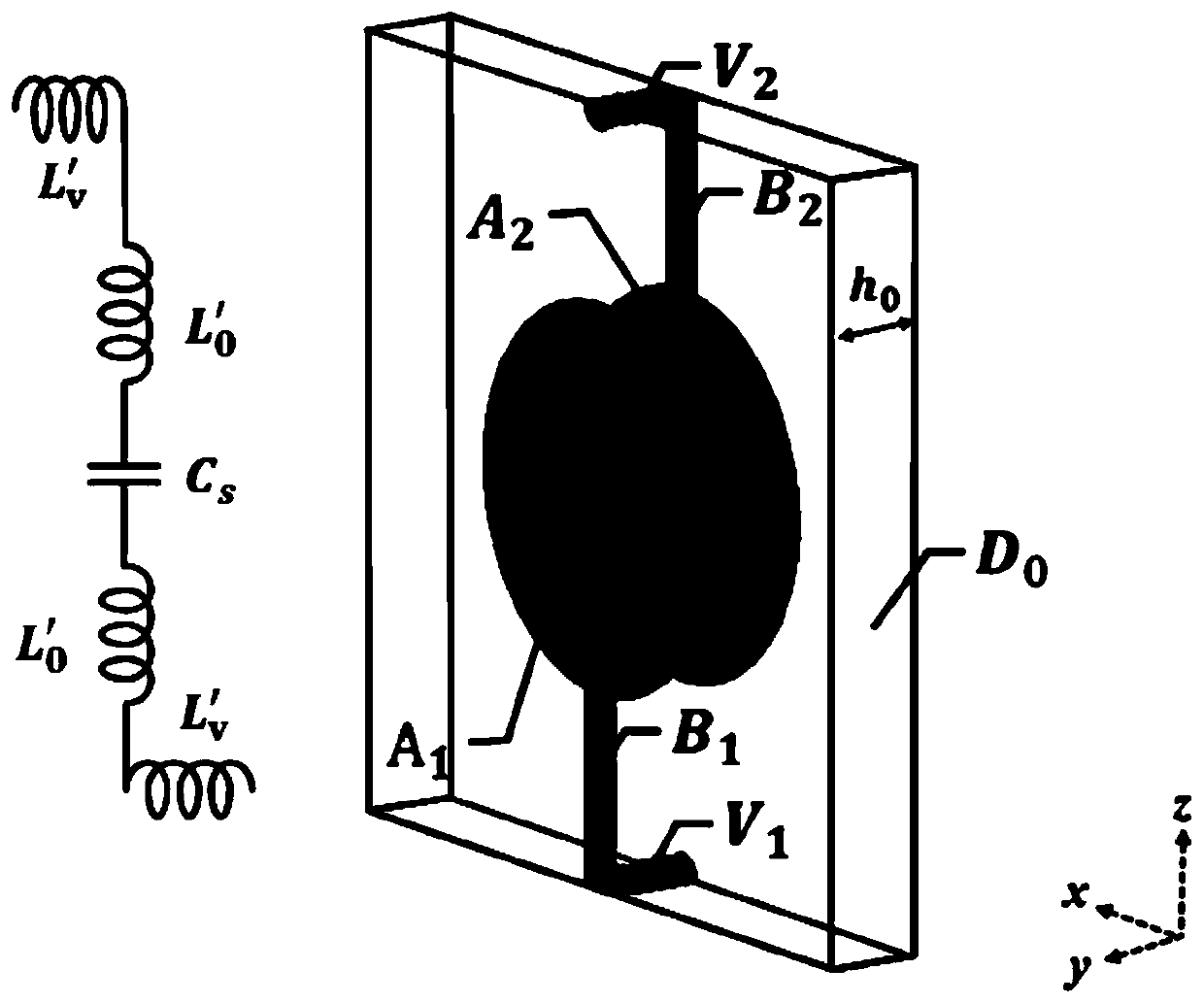

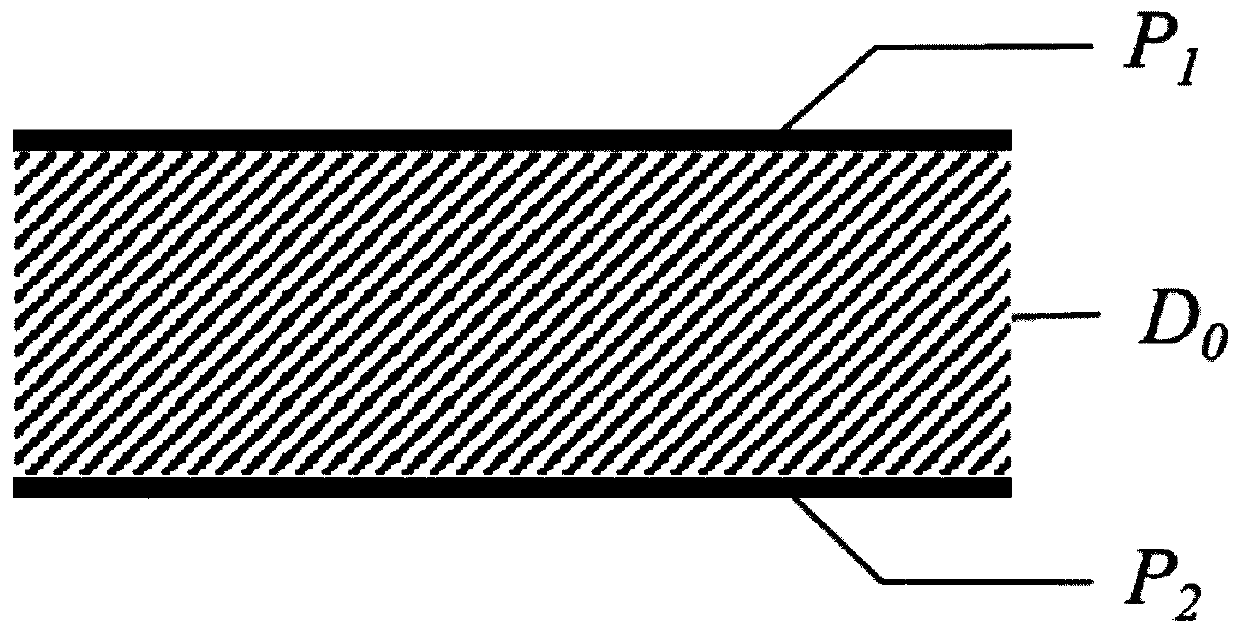

[0047] Such as figure 2 and image 3 As shown, the periodic unit structure includes the top metal patch P 1 , Dielectric board D 0 and the underlying metal patch P 2 , and connect the top metal patch P 1 and the underlying metal patch P 2 Metal vias between the upper and lower halves V 1 and V 2 Composition; top metal patch P 1 Attached to the medium plate D 0 Upper surface, bottom metal patch P 2 Attached to the medium board D 0 Bottom surface, underlying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com