Mesoporous zeolites and methods for the synthesis thereof

A technology of mesoporous zeolite and zeolite, applied in the field of mesoporous zeolite and the manufacture of mesoporous zeolite, can solve the problems of reduced catalytic activity, destabilized structure, lack of necessary acidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

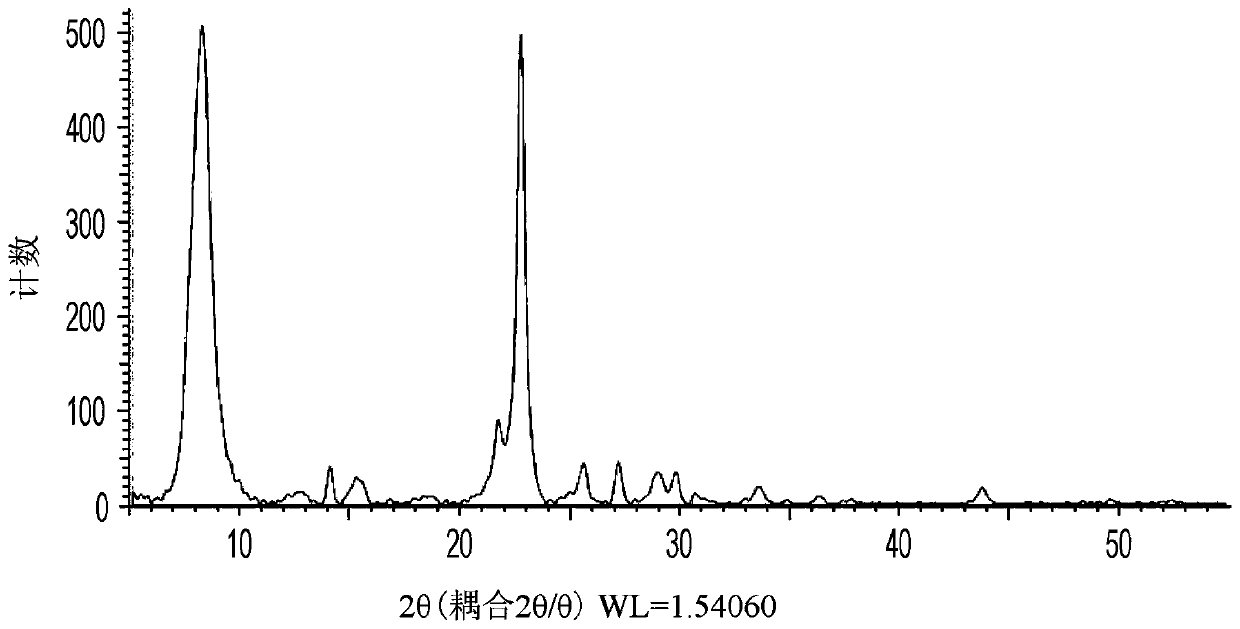

[0060] Using the methods of the present disclosure, mesoporous zeolites were produced to exemplify the previously described properties. Four exemplary methods were performed according to the present disclosure, in which silicon dioxide (SiO 2 ) and alumina (Al 2 o 3 ) ratio changes. Four additional exemplary methods were performed to vary the amount and type of cellulosic material used.

example 1

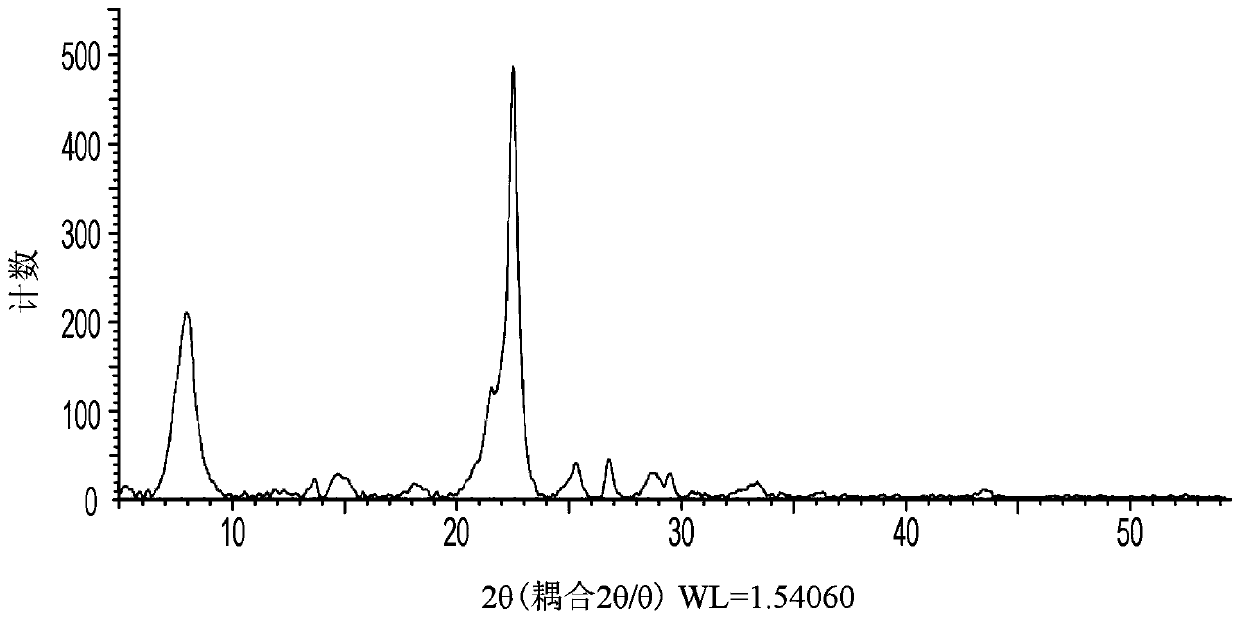

[0061] Example 1 - Si / Al ratio of 15

[0062] By suspending 3.45 grams (g) of fumed silica in 80 g of H 2 O to prepare Example 1. Next, 0.283 g of NaOH in 5 mL of water followed by 15.23 g of TEAOH (35% in water) were both added to the fumed silica. The mixture was stirred vigorously for one hour. In a separate beaker, 1.44g Al(NO 3 ) 3 9H 2 O dissolved in 50g H 2 O, and the resulting solution was added to the suspended fumed silica mixture. The mixture was stirred for 30 minutes. Suspend 1.0 g of previously freeze-dried CNC in about 20 mL of H 2 O and homogenization was performed for 1 hour using a sonic mixer LabRam at an intensity of 80% (70G acceleration). The resulting opaque suspension was added to the mixture and stirred for 30 minutes. Volatiles were removed on a rotary evaporator and the water bath was heated to 60°C. The resulting off-white sticky solid was crushed in a mortar. The resulting glassy gel powder was transferred to a 15 mL crucible placed o...

example 2

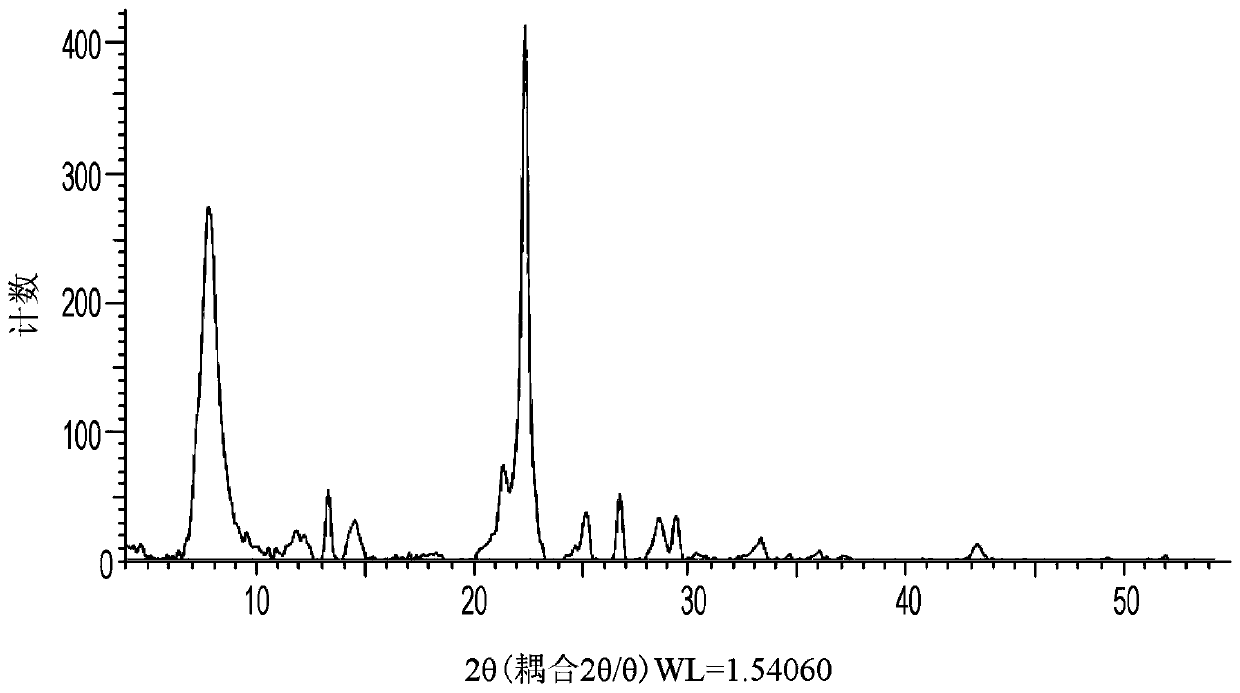

[0063] Example 2 - Si / Al ratio of 30

[0064] By suspending 3.45 grams (g) of fumed silica in 80 g of H 2 O to prepare Example 2. Next, both 0.166 g of NaOH in 5 mL of water and 8.96 g of TEAOH (35% in water) were added to the fumed silica. The mixture was stirred vigorously for one hour. In a separate beaker, 0.720g Al(NO 3 ) 3 9H 2 O dissolved in 20g H 2 O, and the resulting solution was added to the suspended fumed silica mixture. The mixture was stirred for 30 minutes. Suspend 0.75 g of previously freeze-dried CNC in about 20 mL of H 2 O and homogenization was performed for 1 hour using a sonic mixer LabRam at an intensity of 80% (70G acceleration). The resulting opaque suspension was added to the mixture and stirred for 30 minutes. Volatiles were removed on a rotary evaporator and the water bath was heated to 60°C. The resulting off-white sticky solid was crushed in a mortar. The resulting glassy gel powder was transferred to a 15 mL crucible placed on top o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com