Printed circuit board

A printed circuit board and outer layer circuit technology, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of increasing the unit cost of the product and difficulty in forming through holes, so as to reduce the unit cost of the product and reduce the overall thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

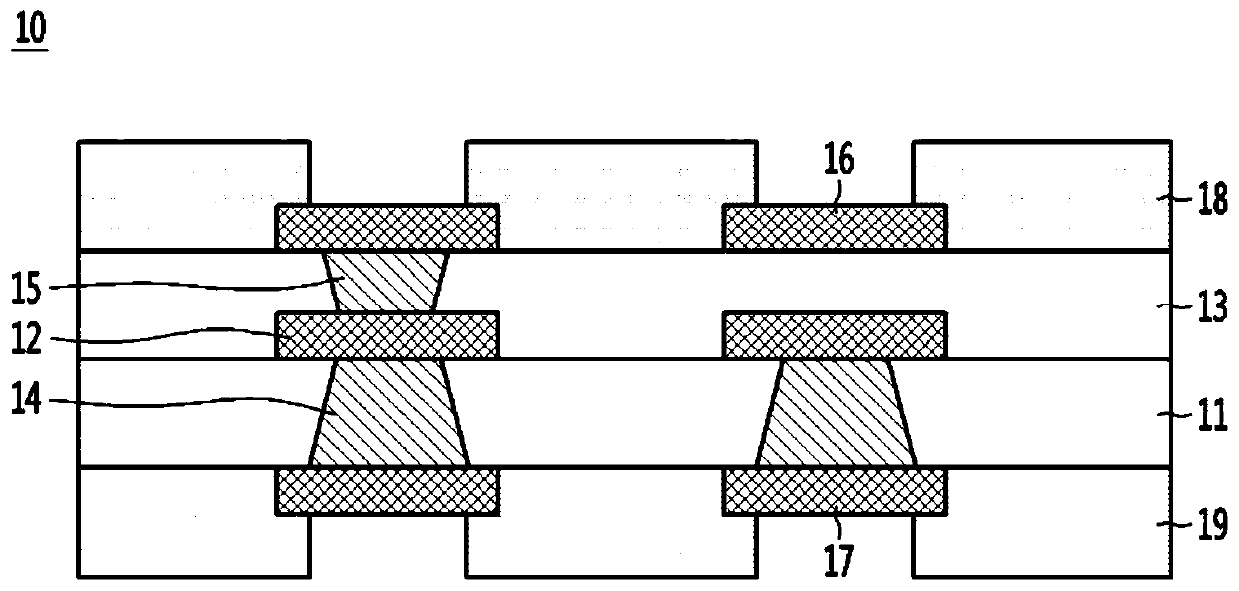

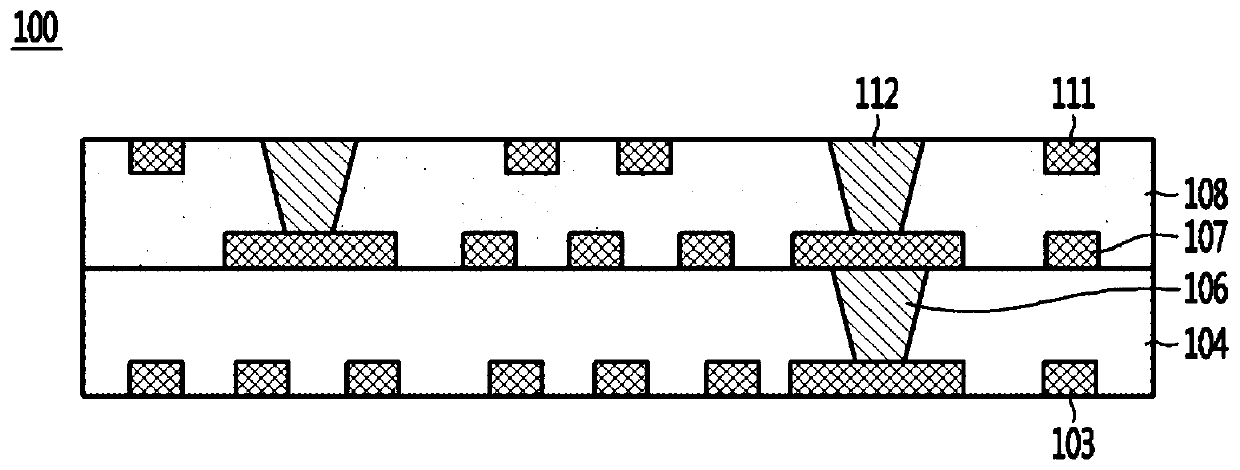

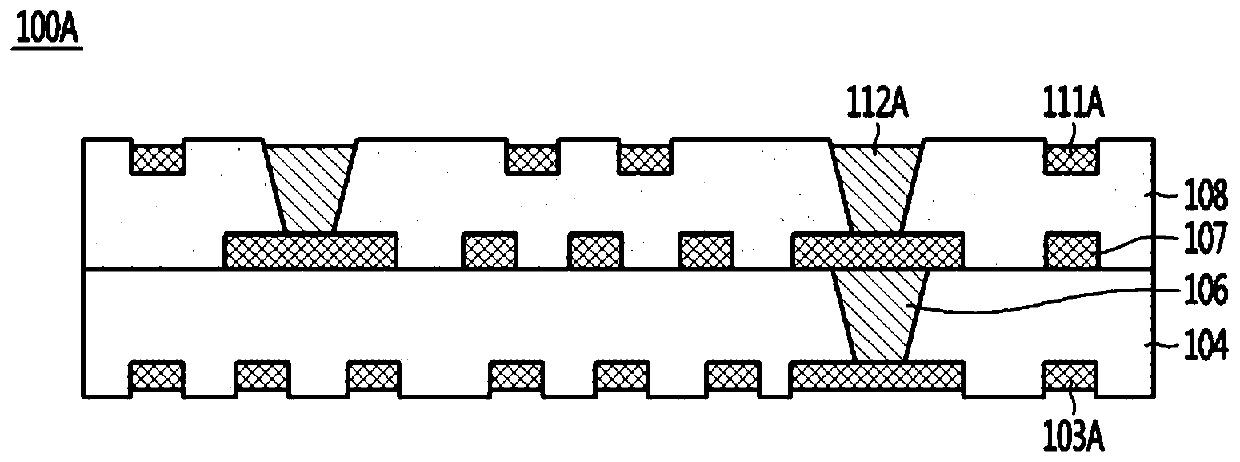

[0053] Hereinafter, embodiments disclosed in this specification will be described in detail with reference to the accompanying drawings, but the same or similar components are denoted by the same reference numerals regardless of the reference numerals, and repeated description thereof will be omitted. The component suffixes 'module' and 'part' used in the following description are given or mixed together only in consideration of ease of authoring the description, and do not have meanings or roles to distinguish from each other. In addition, in describing the embodiments disclosed in this specification, when it is determined that the detailed description of related well-known technologies unnecessarily obscures the gist of the embodiments disclosed in this specification, its detailed description will be omitted. In addition, the drawings are only used to facilitate the understanding of the embodiments disclosed in this specification, and the technical scope disclosed in this spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com