Microbial feed stirring and granulating integrated system

A microbial feed, stirring and granulating technology, applied in the direction of feed, food science, application, etc., can solve the problems of unfavorable fermentation, insufficient straw water absorption, etc., and achieve the effect of good feed preparation and good sterilization and disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

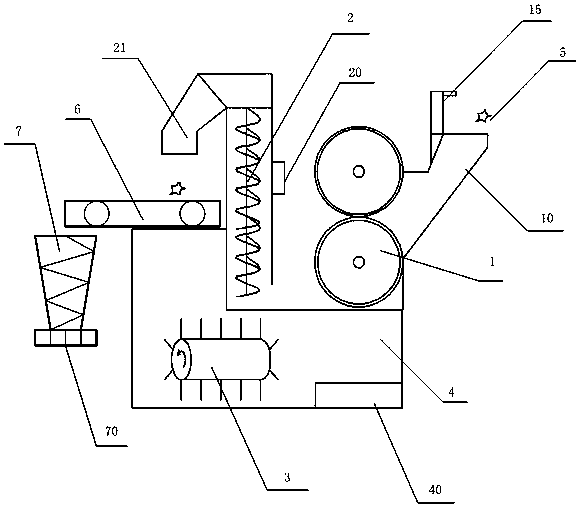

[0019] Such as figure 1 ; The microbial feed mixing and granulation integrated system of this embodiment includes: double-barrel roller 1, screw conveyor pipe 2, agitator 3, fermentation tank 4 and conical extruder 7.

[0020] The double-barrel roller 1 has a feed port 10 and a discharge port, and the discharge port is connected with the fermentation vat 4, so that the extruded straw enters the fermentation vat for fermentation. The fermentation tank is not only used for fermentation, but also used to quickly increase the water content in the feed, so as to facilitate the transformation of nutrients in the feed.

[0021] A stirrer 3 is arranged in the fermentation tank 4, and the stirrer 3 is located below the discharge port of the double-barrel roller 1; thus, it is convenient to stir the straw entering the discharge port.

[0022] Described spiral conveying pipe 2 is installed on the top of described fermenting tank 4; Described spiral conveying pipe 2 is the hollow cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com