A kind of Gao Lunmu pure spinning high-count yarn and its production method and application

A production method and high-count yarn technology, which is applied in the textile field, can solve the problems that it is difficult to obtain high-quality high-count yarn, and achieve the effects of excellent color fixation, full color and smooth hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

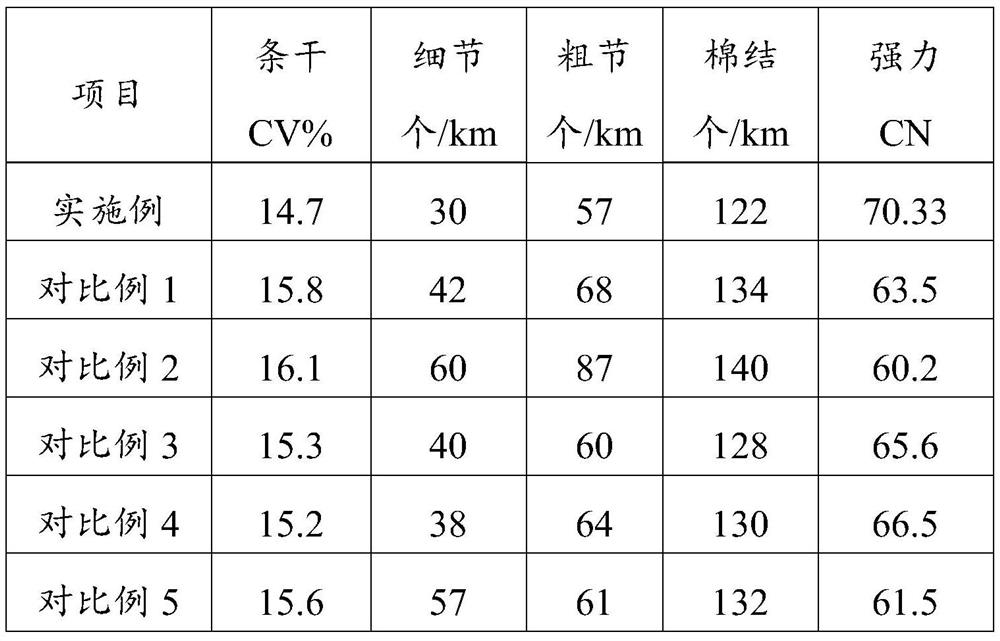

Examples

Embodiment 1

[0036] A high-count yarn purely spun from Gaolun wood. The high-count yarn purely spun from Gaolun wood uses high-count wood as a raw material and is produced through the following process steps:

[0037] (1) wet pretreatment

[0038] Before production, the Gaolun wood fiber needs to be pre-treated with humidity. Mix the antistatic agent with water in a ratio of 1:3, treat the raw material in the form of atomization, and seal it for 24 hours to keep warm and moisturize. The temperature is controlled at 26~ 28°C, humidity controlled at 55-58%;

[0039] (2) Blowing and carding process

[0040] Due to the poor cohesion of Gaolun wood fibers, a cotton collection device is used in the blowing and carding process to reduce the occurrence of cotton webs and ensure the uniformity of the raw sliver. The carding clothing and other special parts have been polished and angled, and the carding process has been optimized. The drop speed of the picker is 3mm each time, the speed is 960r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com