Wall mud containing biomass charcoal ash and preparation method thereof

A technology of biomass charcoal and wall mud, which is applied in the field of building materials, can solve the problems of unsatisfactory comprehensive performance, poor bonding and crack resistance, and increased use costs, so as to promote compatibility, improve aging resistance, and enhance stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

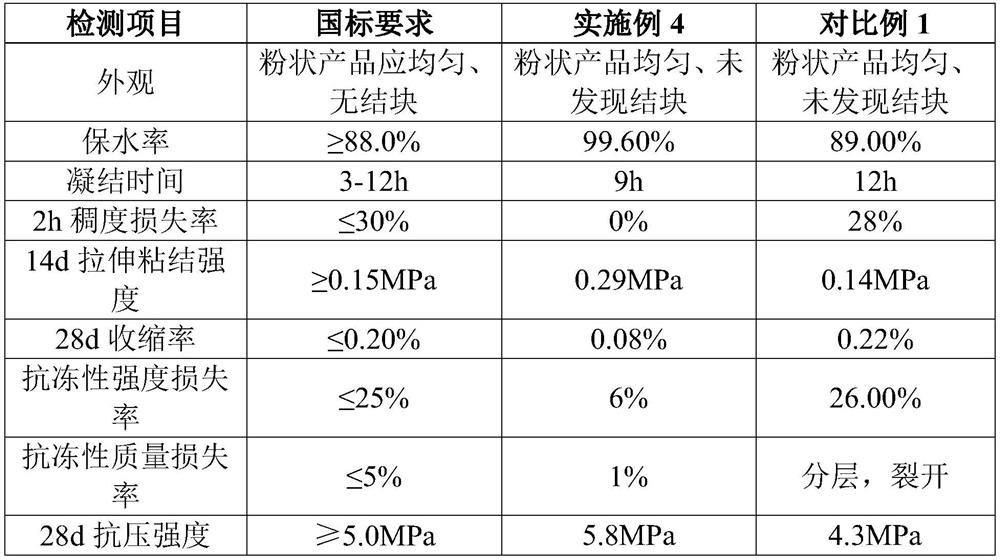

Examples

Embodiment 1

[0056] A wall mud containing biomass charcoal, comprising the following components in weight percentage:

[0057] Biomass charcoal 40%,

[0058] fly ash 9.3%,

[0059] Cement 40%,

[0060] Attapulgite 3%,

[0061] Vitrified Microbeads 5%,

[0062] Water repellant 0.5%,

[0063] 0.2% defoamer,

[0064] Lignocellulose 0.2%,

[0065] Polypropylene fiber 0.2%,

[0066] Hydroxypropyl methylcellulose 0.8%,

[0067] and redispersible latex powder 0.8%;

[0068] The waterproofing agent is monomethyltrichlorosilane, and the defoamer is siloxane;

[0069] The particle diameter of the biomass charcoal is 100-300 mesh, the particle diameter of the fly ash is 100-300 mesh, the particle diameter of the attapulgite is 100-300 mesh, the vitrified microbead The particle size is 100-300 mesh.

[0070] The preparation method of the above-mentioned wall mud containing biomass charcoal ash may further comprise the steps:

[0071] Take biomass charcoal ash, fly ash, cement, attapulgite,...

Embodiment 2

[0073] A wall mud containing biomass charcoal, comprising the following components in weight percentage:

[0074] Biomass Charcoal Ash 50%,

[0075] fly ash 4%,

[0076] cement 25%,

[0077] Attapulgite 6%,

[0078] Vitrified Microbeads 5.2%,

[0079] Water repellent 0.8%,

[0080] 0.4% defoamer,

[0081] Lignocellulose 0.4%,

[0082] Polypropylene fiber 1%,

[0083] Hypromellose 1%,

[0084] and redispersible latex powder 1.2%;

[0085] The waterproofing agent is sodium methyl silicate, and the defoamer is allyl polyoxyalkyl ether and silicone oil;

[0086] The particle diameter of the biomass charcoal is 100-300 mesh, the particle diameter of the fly ash is 100-300 mesh, the particle diameter of the attapulgite is 100-300 mesh, the vitrified microbead The particle size is 100-300 mesh.

[0087] The preparation method of the above-mentioned wall mud containing biomass charcoal ash is the same as that of Example 1, except that the stirring rate is 50 r / min.

Embodiment 3

[0089] A wall mud containing biomass charcoal, comprising the following components in weight percentage:

[0090] Biomass Charcoal Ash 51.4%,

[0091] Fly Ash 10%,

[0092] Cement 20%,

[0093] Attapulgite 5%,

[0094] Vitrified Microbeads 10%,

[0095] Water repellant 0.5%,

[0096] Defoamer 0.3%,

[0097] Lignocellulose 0.3%,

[0098] Polypropylene fiber 0.5%,

[0099] Hypromellose 1%,

[0100] and redispersible latex powder 1%;

[0101] The defoamer is siloxane, and the waterproofing agent is silane;

[0102] The particle diameter of the biomass charcoal is 100-300 mesh, the particle diameter of the fly ash is 100-300 mesh, the particle diameter of the attapulgite is 100-300 mesh, the vitrified microbead The particle size is 100-300 mesh.

[0103] The preparation method of the above-mentioned wall mud containing biomass charcoal ash is the same as that of Example 1, except that the stirring rate is 50 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile bond strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com