Automatic temperature-control and cooling device for lithium battery

A cooling device, lithium battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of inability to quickly reduce local temperature, affecting battery use, excessive heat accumulation, etc., to ensure sealing, improve Cooling capacity, the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

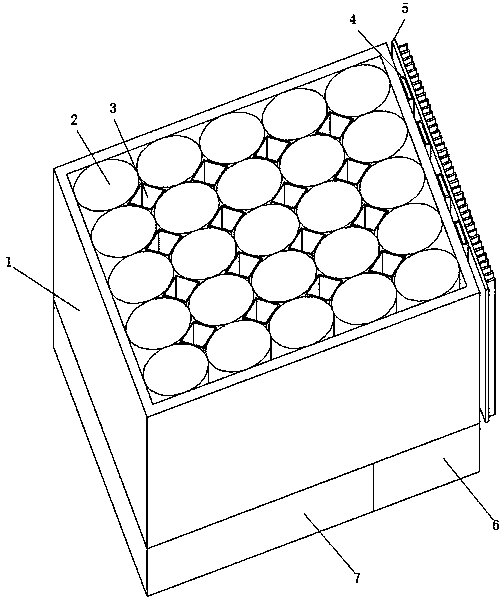

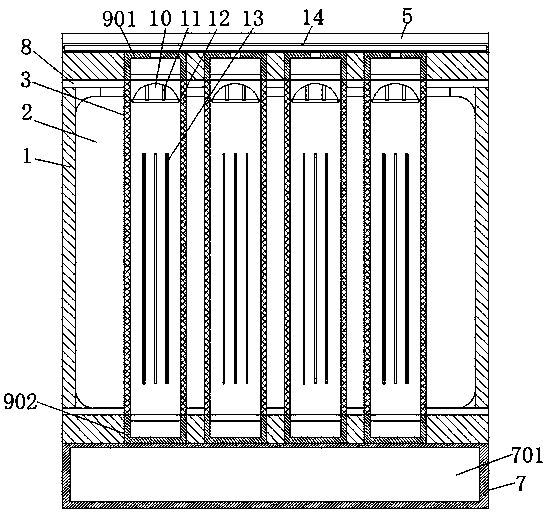

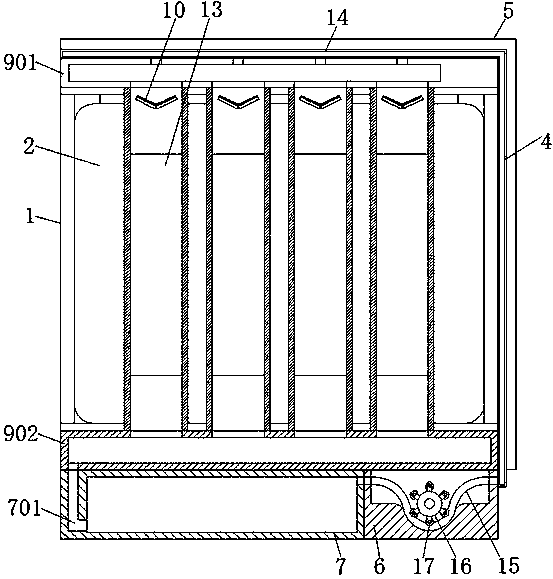

[0029] refer to Figure 1-5 , a lithium battery automatic temperature control and cooling device, including a main body 1, the interior of the main body 1 is provided with a number of batteries 2 and cooling pipes 3, the bottom of the main body 1 is welded with a liquid storage box 7, and one side of the liquid storage box 7 is welded with The fixed box 6 is provided with a driving mechanism inside the fixed box 6, and the top and bottom ends of the cooling pipe 3 are respectively welded with a first connecting pipe 901 and a second connecting pipe 902, and the top of the first connecting pipe 901 is welded with a collecting pipe 14, One end of the collecting pipe 14 is welded with a cooling pipe 4, one side of the cooling pipe 4 and the top of the collecting pipe 14 are welded with a cooling plate 5, and the inside of both sides of the cooling pipe 3 is welded with a fixed block 12, between the two fixed blocks 12 The same elastic plate 10 is welded between them, the top of t...

Embodiment 2

[0039] refer to Image 6 , an automatic temperature control and cooling device for a lithium battery. Compared with Embodiment 1, in this embodiment, in order to increase the heat dissipation performance of the device, a condensing plate 18 is provided inside the liquid storage box 7, and the condensing plate 18 is S-shaped, which can be fully integrated with the The coolant inside the cooling box 7 contacts to reduce the temperature of the coolant. One end of the hose 15 is provided with a temperature control switch, which is electrically connected to the condensation plate 18. When the coolant inside the hose 15 has been cooled When the temperature is too high, the temperature control switch is connected to the condensing plate 18, so that the temperature of the cooling liquid inside the liquid storage box 7 is reduced, and the heat dissipation performance is enhanced.

[0040] When in use, when the motor drives the rotating wheel 16 to rotate, the roller 17 will rotate acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com