Ball-milling debromination method for nonmetal components of waste circuit board

A waste circuit board and non-metallic technology, which is applied to chemical instruments and methods, solid waste removal, solid separation, etc., can solve the problems of easy damage to the non-metallic component resin structure, and the effect of debromination by ball milling is not obvious, and achieves remarkable results. Economic benefits, easy to break, improve the effect of debromination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

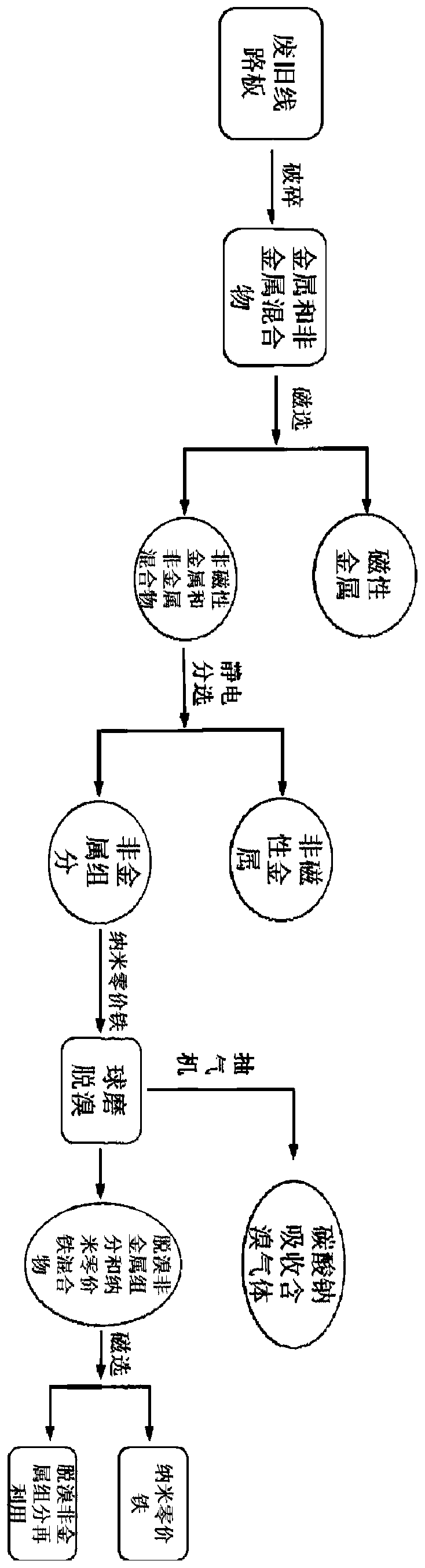

[0034] Example 1 A ball milling method for debromination of non-metallic components of waste circuit boards

[0035] Use the following method to debrominate the non-metallic components of waste circuit boards by ball milling:

[0036] S1. Hammer crush waste circuit boards to obtain particles with a particle size of 5mm. Magnetic separators are used to separate and recover magnetic metals such as iron and nickel, and high-voltage electrostatic separation is used to recover non-magnetic metals such as copper and zinc to obtain metal groups. Parts and non-metallic components;

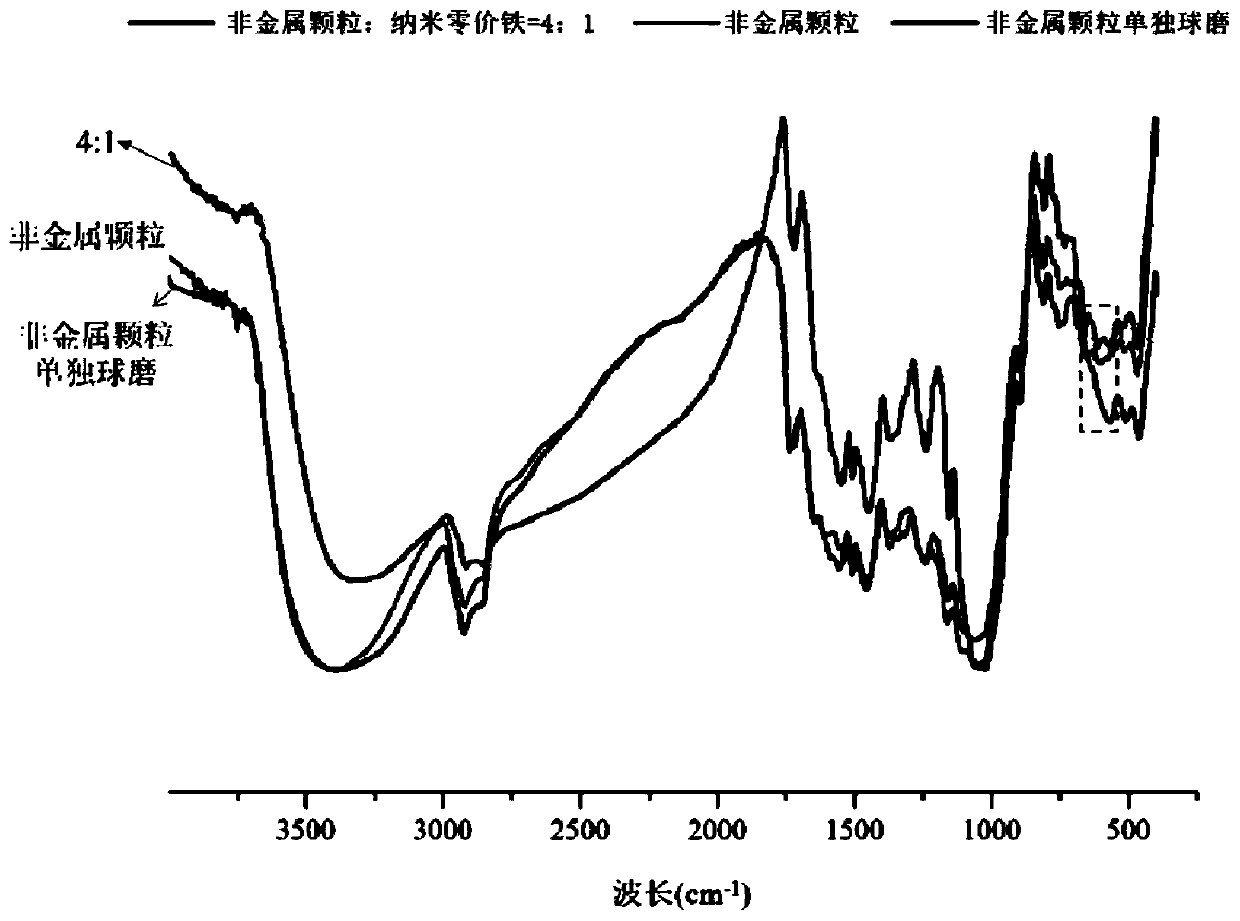

[0037] S2. Mix 0.96g of the non-metallic component obtained in step S1 with 0.24g of nanometer zero-valent iron, place it in a planetary ball mill, set the speed of the ball mill to 220r / min, change the direction of rotation once every 30min, and use 5mm balls for ball milling 30h, at the same time pump out the gas in the ball mill and absorb it with sodium carbonate solution;

[0038] S3. Collect the ba...

Embodiment 2

[0039] Example 2 A ball milling method for debromination of non-metallic components of waste circuit boards

[0040] Use the following method to debrominate the non-metallic components of waste circuit boards by ball milling:

[0041] S1. Hammer crush waste circuit boards to obtain particles with a particle size of 5mm. Magnetic separators are used to separate and recover magnetic metals such as iron and nickel, and high-voltage electrostatic separation is used to recover non-magnetic metals such as copper and zinc to obtain metal groups. Parts and non-metallic components;

[0042] S2. Mix 1.20 g of the non-metallic component obtained in step S1 with 0.24 g of nanometer zero-valent iron, place in a planetary ball mill, set the speed of the ball mill to 220r / min, change the direction of rotation once every 30min, and use 5mm balls for ball milling 30h, at the same time pump out the gas in the ball mill and absorb it with sodium carbonate solution;

[0043] S3. Collect the bal...

Embodiment 3

[0044] Example 3 A ball milling method for debromination of non-metallic components of waste circuit boards

[0045] Use the following method to debrominate the non-metallic components of waste circuit boards by ball milling:

[0046] S1. Hammer crush waste circuit boards to obtain particles with a particle size of 4 mm. Magnetic separators are used to separate and recover magnetic metals such as iron and nickel, and high-voltage electrostatic separation is used to recover non-magnetic metals such as copper and zinc to obtain metal groups. Parts and non-metallic components;

[0047] S2. Take 1.08 g of non-metallic components obtained in step S1 and mix them with 0.24 g of nanometer zero-valent iron, place them in a planetary ball mill, set the speed of the ball mill to 220r / min, change the direction of rotation once every 30min, and use 8mm balls for ball milling 30h, at the same time pump out the gas in the ball mill and absorb it with sodium carbonate solution;

[0048] S3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com