A layer-by-layer embedding method for 3D printed concrete structures

A technology of concrete structure and concrete layer, applied in the field of 3D printing and building structure, can solve the problems of limited printing structure form and bearing capacity, and achieve the effect of improving the shear resistance between layers, improving the integrity and improving the integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

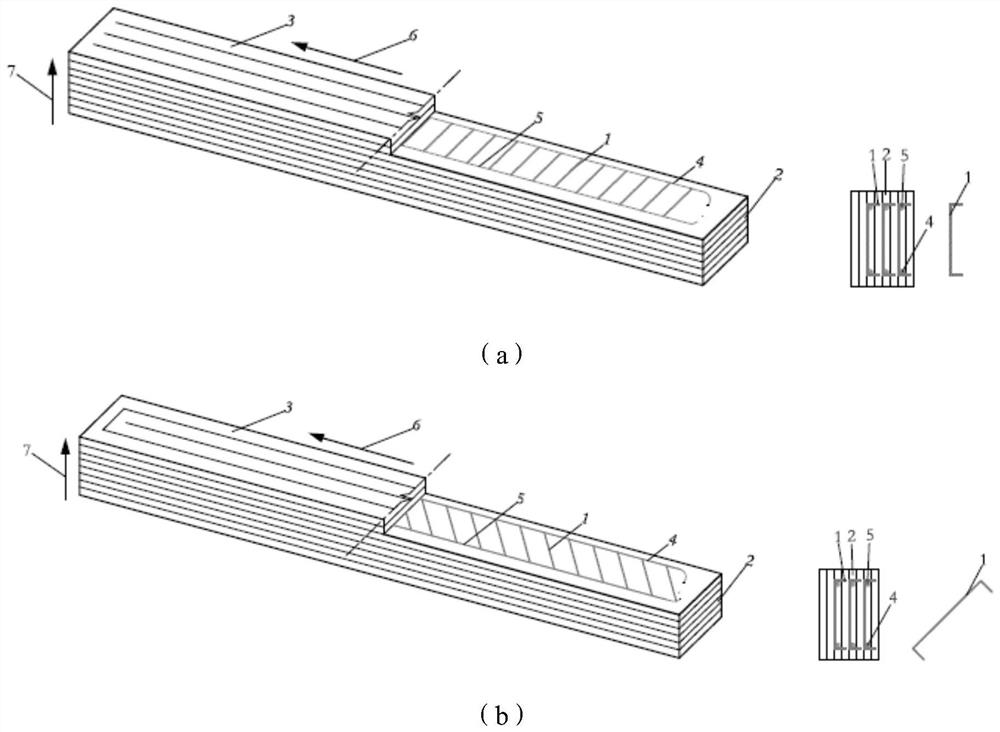

[0031] Example 1: Interlayer reinforcement of 3D printed concrete beam components using a nail-embedded structure

[0032] 3D printed concrete beam components such as side-laying tiled 3D printed concrete beam members embedded in the structure figure 1 As shown, a is vertical stud reinforcement, b is oblique stud reinforcement. The method for interlayer reinforcement of 3D printed concrete beam members provided in this embodiment includes the following steps:

[0033] (1) The size of the 3D printed concrete beam member is determined by the width of the printed strip 3 and the thickness of the printed layer 2, and the bearing capacity of the beam member is calculated from the size of the beam member and the mechanical properties of the materials used according to the design principle of reinforced concrete structure, and the embedding is determined. Order the size, layout, layout spacing and layout quantity of structure 1. The size of the embedded structure includes the lengt...

Embodiment 2

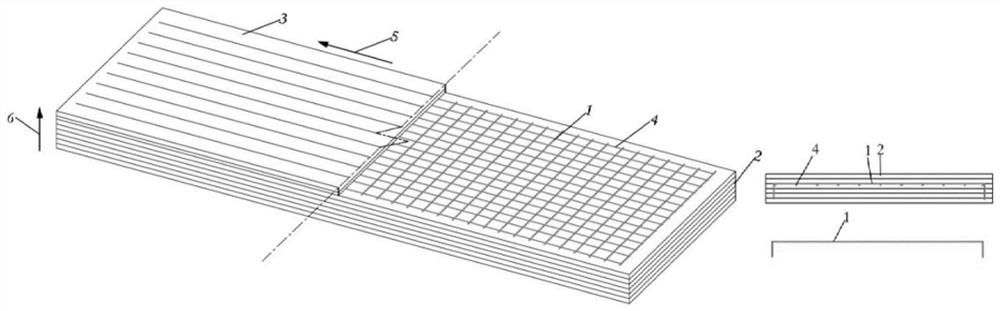

[0037] Example 2: Interlayer reinforcement of 3D printed concrete slab structure using embedded structure

[0038] Embedding structures for inverted tiling 3D printed concrete slab components such as figure 2 shown. The method for interlayer reinforcement of 3D printed concrete slab members provided in this embodiment includes the following steps:

[0039] (1) The size of the 3D printed concrete slab is determined by the width of the printed strip 3 and the thickness of the printed layer 2, and the bearing capacity of the slab is calculated from the size of the slab and the mechanical properties of the materials used in accordance with the design principles of reinforced concrete structures to determine the embedding. Order the size, layout, layout spacing and layout quantity of structure 1. The size of the embedded structure includes the length and diameter of the embedded structure. The length of the embedded structure is determined according to the cross-sectional size o...

Embodiment 3

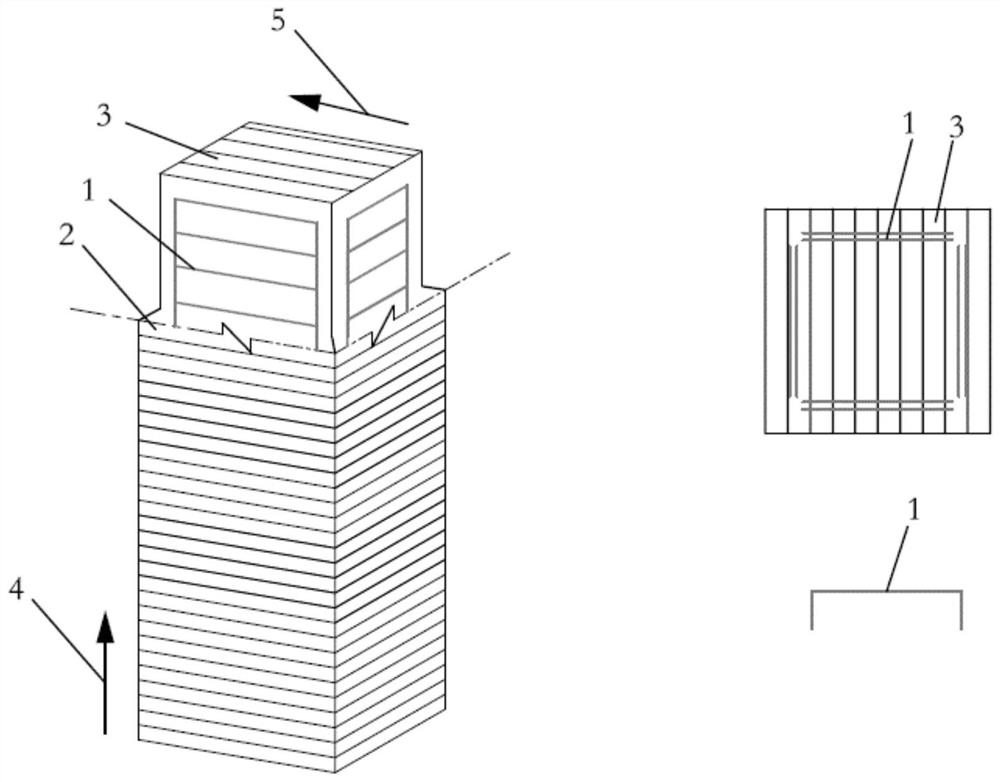

[0043] Example 3: Interlayer reinforcement of 3D printed concrete column components using an embedded structure

[0044] Embedding structure for interlayer reinforcement of superimposed 3D printed concrete column components such as image 3 shown. The method for interlayer reinforcement of 3D printed concrete column members provided in this embodiment includes the following steps:

[0045] (1) The size of the 3D printed concrete column member is determined from the width of the printed strip 3 and the thickness of the printed layer 2, and the bearing capacity of the column member is calculated according to the design principle of the reinforced concrete structure based on the size of the column member and the mechanical properties of the materials used, Determine the size, layout, layout pitch and layout quantity of the embedded structure 1 . The size of the embedded structure includes the length and diameter of the embedded structure. The length of the embedded structure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com