Reactor capable of stratification and near true plug-flow conditions and its treatment method

A reactor, stratified flow technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of long diffusion length and low mixing efficiency, achieve volume reduction, Uniform distribution guarantees the effect of shortening the mass transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

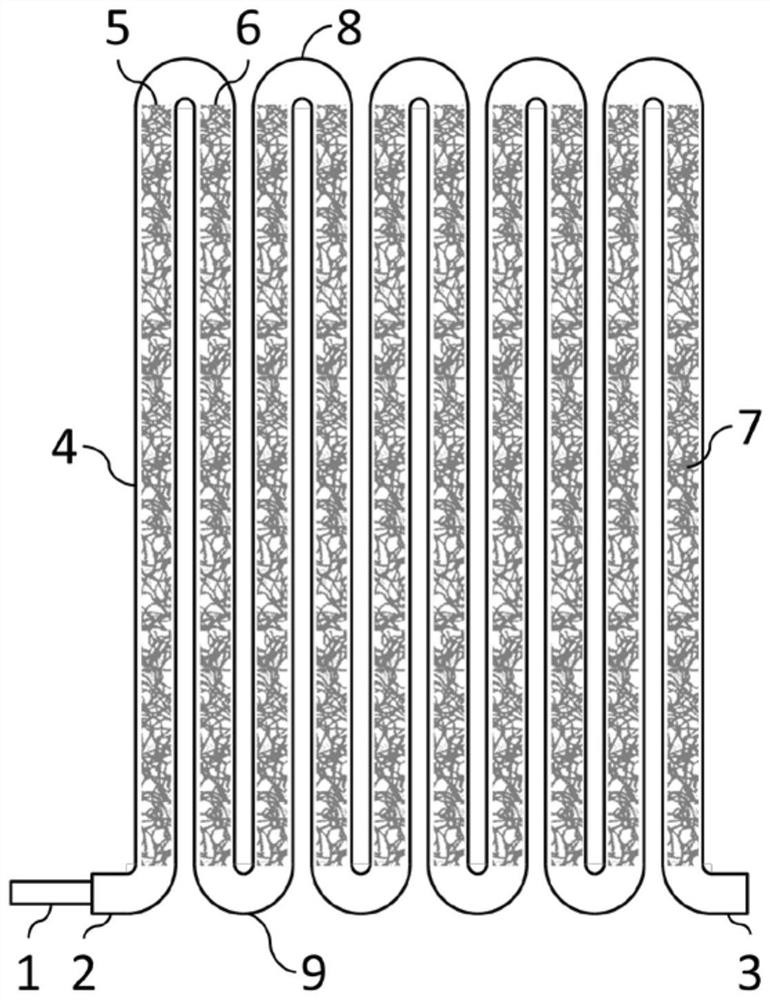

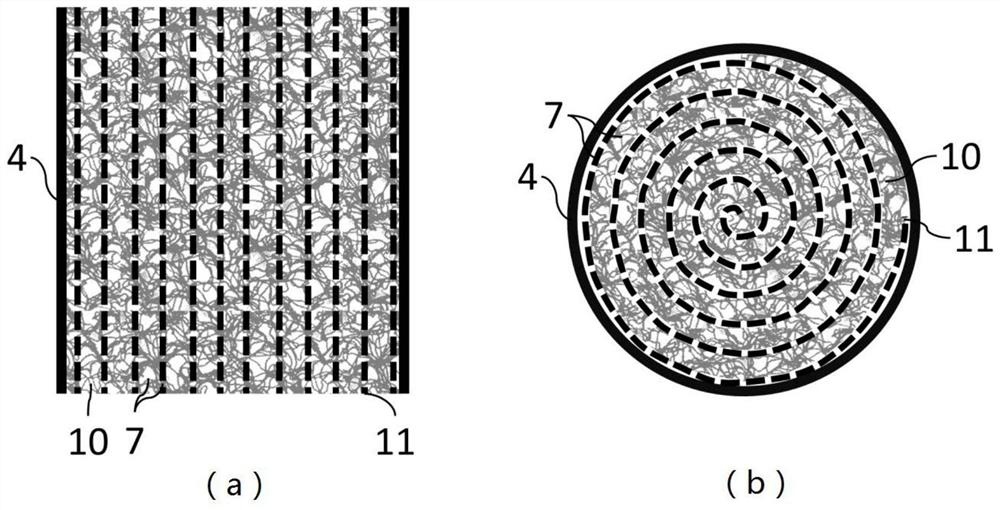

[0047] Such as figure 1 As shown, a plug-flow reactor includes a reactor body, the reactor body 4 is provided with a reactor inlet 2 and a reactor outlet 3, and the reactor inlet 2 communicates with a water inlet pipe 1 . The reactor body 4 is filled with a composite biological carrier 7, the composite biological carrier 7 includes at least two biological carrier layers, the composite biological carrier 7 includes a main biological carrier 10 and a secondary biological carrier 11 connected to each other, the The porosity of the main biological carrier 10 is higher than that of the secondary biological carrier 11 . The reactor body 4 includes an upflow section 5 and a downflow section 6 interconnected in sequence, and the flow direction of the fluid in the upflow section 5 and the downflow section 6 is perpendicular to the horizontal plane. The raw sewage enters the reactor body 4 at the reactor inlet 2 through the water inlet pipe 1 , and the treated wastewater is discharged ...

Embodiment 2

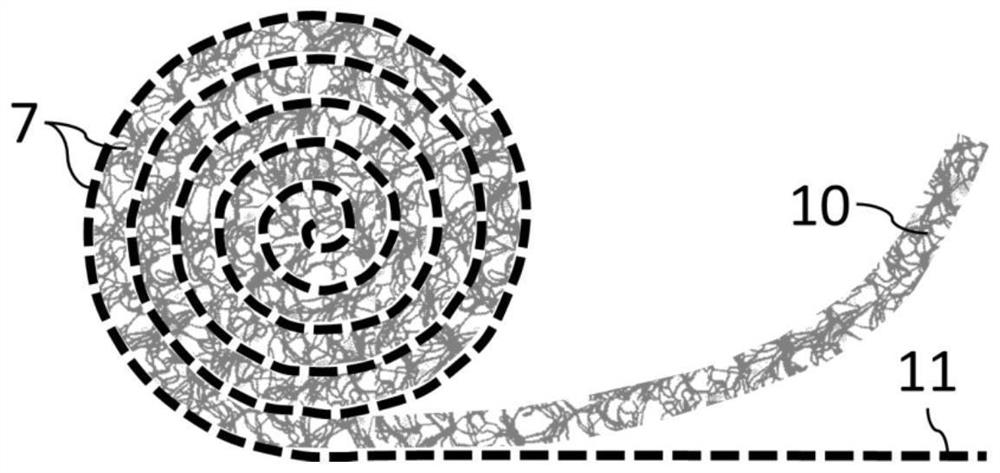

[0061] On the basis of Example 1, such as Figure 4 As shown, the high-porosity main biological carrier 10 and the low-porosity secondary biological carrier 11 can be combined and used in multiple layers. That is, at least two main biological carriers 10 and at least two secondary biological carriers 11 can be used. for example, Figure 4 A composite biocarrier 7 is shown, comprising two primary biocarrier layers, a first primary biocarrier layer 12 and a second primary biocarrier layer 13, and two secondary biocarrier layers, a first secondary biocarrier layer layer 14 and second by-biological carrier layer 15.

[0062] The second main biological carrier layer 13, the second secondary biological carrier layer 15, the first main biological carrier layer 12, and the first secondary biological carrier layer 14 are stacked together successively and curled into an Archimedes spiral, because the secondary biological carrier The layer thickness is very small, the pitch of the spi...

Embodiment 3

[0067] A plug-flow biological reaction treatment method, the liquid to be treated is processed by the plug-flow reactor as described in the above embodiment 1 or embodiment 2, and the liquid to be treated contains one or more dissolved or suspended substances . The superficial velocity v of the liquid in the reactor body pf pf = 0.05-0.15 m / s. The lower flow rate of the control liquid induces less turbulence resulting in less head loss and thus lower energy consumption.

[0068] Further, the composite biological carrier comprises at least one main biological carrier layer and at least one secondary biological carrier layer, and the liquid is divided into multiple layers between the secondary biological carrier layers to realize laminar flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com