Tube supply device and tube supply method of automatic tube feeding machine of bottle making machine

A bottle-making machine and automatic technology, applied in the direction of manufacturing tools, glass molding, glass re-molding, etc., can solve the problems of waste of material tubes, increase the production cost of enterprises, damage, etc., to ensure stability and reliability, prevent The shaking of the material tube, the effect of improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

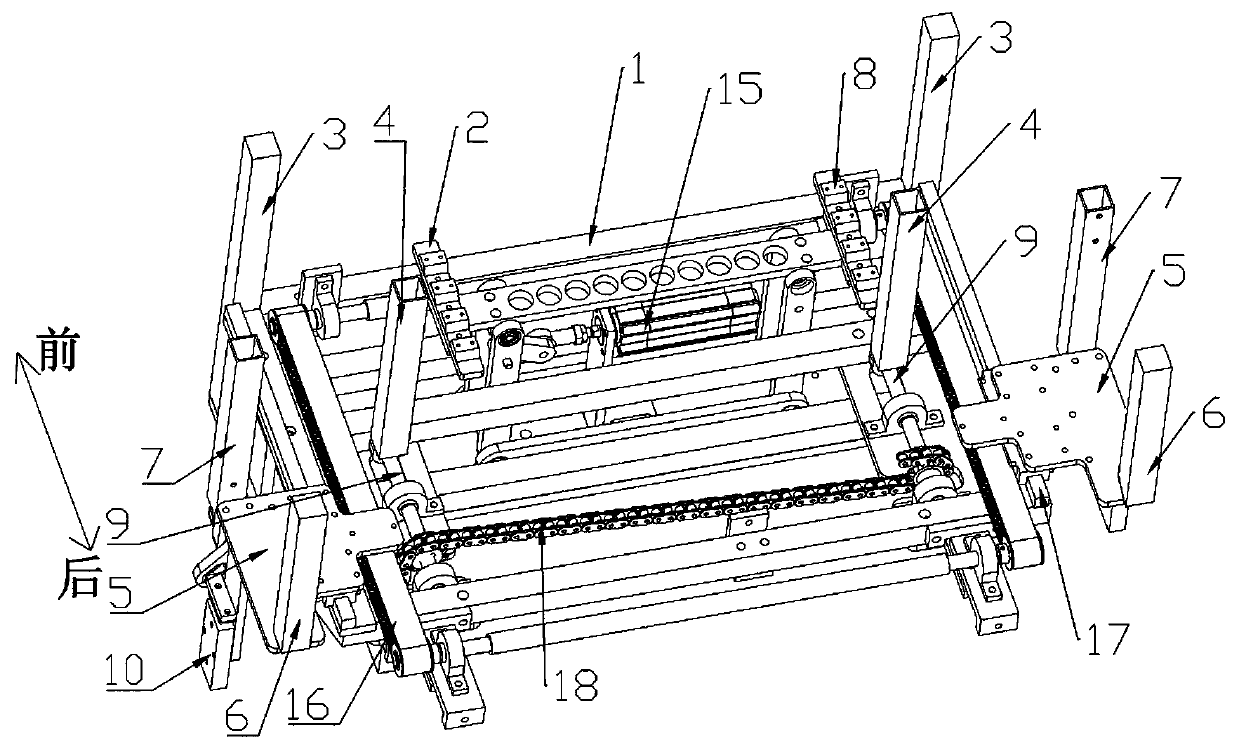

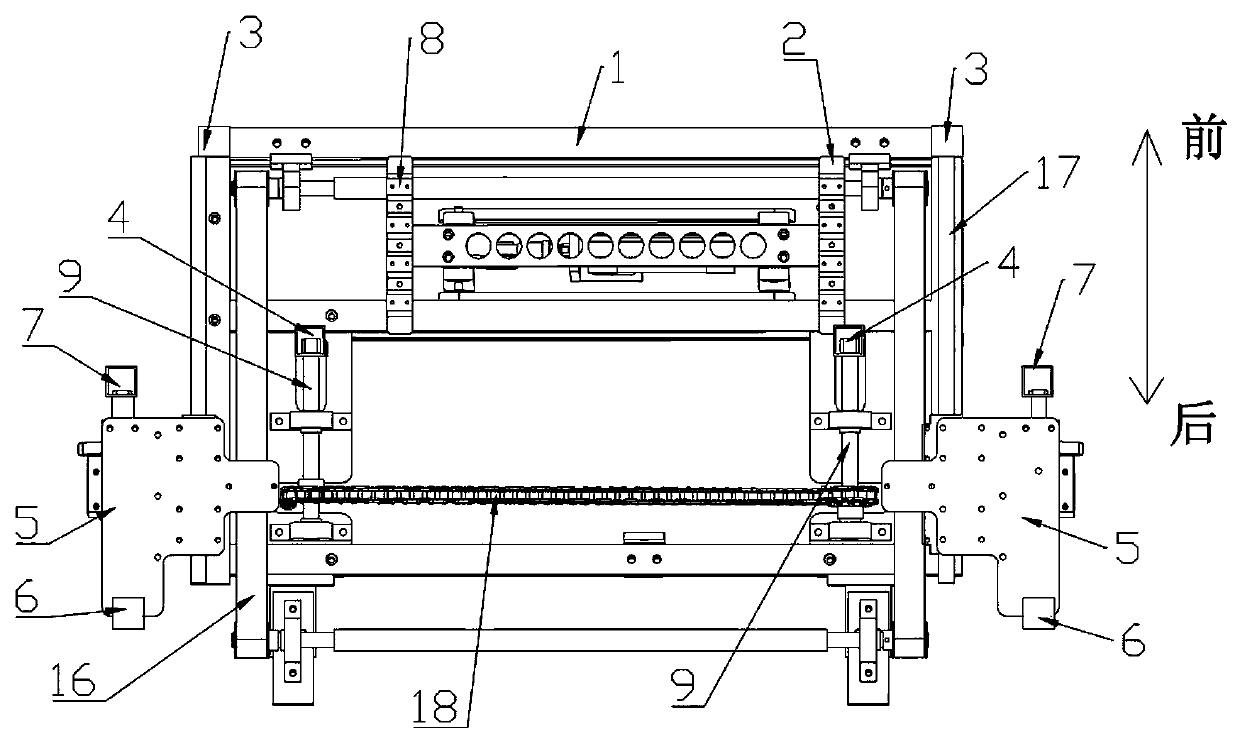

[0052] Example 1 A tube supply device for an automatic tube loading machine for a bottle making machine

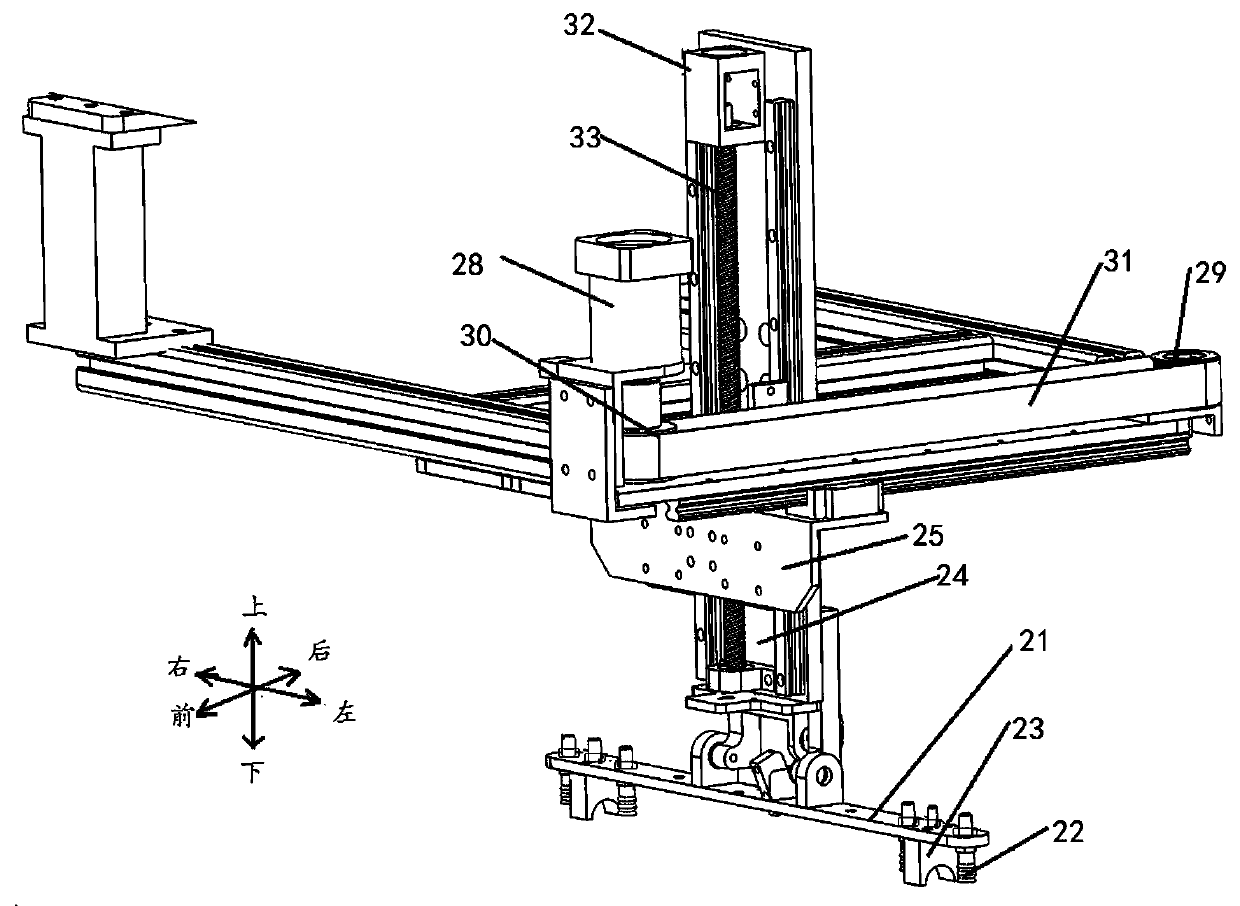

[0053] Such as figure 1 As shown, this embodiment includes a storage tube mechanism for storing the material tube, a suction cup assembly for absorbing the material tube, a transfer mechanism for controlling the transfer and positioning of the suction cup assembly, and a transfer mechanism for pushing the material tube to the bottle making machine automatically. The tube machine transfers the push-up mechanism of the intubation mechanism.

[0054] The suction cup assembly is assembled on the output control end of the transfer mechanism. The tube taking position of the suction cup assembly corresponds to the output port of the material tube of the tube storage mechanism. The transfer output position of the material tube of the suction cup assembly corresponds to the material tube input port of the push-up mechanism. The material pipe output port of the lifting mechanism co...

Embodiment 2

[0093] Embodiment 2 A method for supplying tubes of an automatic tube loading machine for a bottle making machine

[0094] This embodiment is realized by utilizing the material tube transfer mechanism of the automatic tube loading machine of the bottle making machine in Example 1, and each part enters the working state under the control of the controller, and the controller in this embodiment is a PLC programmable controller. Under the orderly control of the PLC programmable controller, the working process of each part is as follows:

[0095] Step 1: Store the material tube in the material tube storage space of the storage tube mechanism by the storage tube mechanism

[0096] S1. The custodial plate 2 descends, and the movable storage tube limiter 4 is placed in the release position

[0097] After the material tube on the custodian plate 2 is used up, the output end of the expander 15 is extended along the axis of the material tube, and the second movable part 13 is driven to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com