Preparation method of fiber-reinforced flexible silica aerogel

A silica and fiber reinforced technology, used in ceramic products, applications, household appliances, etc., can solve the problems of aerogel application range, poor strength and elasticity of silica aerogel, easy wear and tear, etc. Achieve the effect of improving flexibility, easy process and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of fiber-reinforced flexible silica airgel, the steps are as follows:

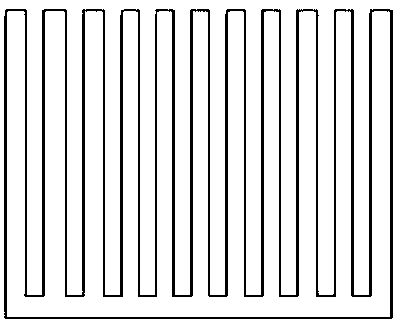

[0027] (1) Design the carbon fiber into a comb shape (such as figure 1 shown), the distance between two adjacent comb teeth is 0.3 cm;

[0028] (2) Mix the composite silicon source, absolute ethanol and water evenly, and then add NH in sequence 4 F solution and ammonia are stirred evenly to obtain silica sol; the composite silicon source is a composite silicon source composed of methyltrimethoxysilane and dimethyldimethoxysilane in a molar ratio of 1:1; in molar ratio, the composite silicon Source: absolute ethanol: water = 1:12:4; NH 4 The amount of F solution added is guaranteed in molar ratio, NH 4 F: Composite silicon source = 0.003: 1; 3 : composite silicon source=0.015:1;

[0029] (3) Immerse the carbon fiber in the silica sol, let it stand after the impregnation is completed, and obtain the silica gel;

[0030] (4) Aging the silica gel obtained in step (3) at 60 °C ...

Embodiment 2

[0034] A preparation method of fiber-reinforced flexible silica airgel, the steps are as follows:

[0035] (1), design the glass fiber into a comb shape (such as figure 1 shown), the distance between two adjacent comb teeth is 0.5 cm;

[0036] (2) Mix the composite silicon source, absolute ethanol and water evenly, and then add NH in sequence 4 F solution and ammonia are stirred evenly to obtain silica sol; the composite silicon source is a composite silicon source composed of methyltriethoxysilane and hydroxyl silicone oil in a molar ratio of 1:2, and the molar weight of hydroxyl silicone oil is represented by repeating unit (CH 3 ) 2 SiO 2 To measure the molar weight of hydroxy silicone oil = the quality of hydroxy silicone oil / (CH 3 ) 2 SiO 2 molecular weight; in molar ratio, composite silicon source: absolute ethanol: water = 1:10:3; NH 4 The amount of F solution added is guaranteed in molar ratio, NH 4 F: Composite silicon source = 0.008: 1; 3 : composite silic...

Embodiment 3

[0042] A preparation method of fiber-reinforced flexible silica airgel, the steps are as follows:

[0043] (1), design the ramie fiber into a comb shape (such as figure 1 shown), the distance between two adjacent comb teeth is 0.8 cm;

[0044] (2) Mix the composite silicon source, absolute ethanol and water evenly, and then add NH in sequence 4F solution and ammonia are stirred evenly to obtain silica sol; the composite silicon source is a composite silicon source composed of ethyltrimethoxysilane and dimethyldiethoxysilane in a molar ratio of 1:3; in molar ratio, the composite silicon Source: absolute ethanol: water = 1:8:2; NH 4 The amount of F solution added is guaranteed in molar ratio, NH 4 F: Composite silicon source = 0.002:1; the amount of ammonia added is guaranteed in molar ratio, NH 3 :Composite silicon source=0.006:1.

[0045] (3), impregnating the ramie fiber in the silica sol, and standing still after the impregnation is completed, to obtain the silica gel; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com