A kind of polymer carrier and its preparation method and its method of separating and purifying tea saponin

A separation and purification, polymer technology, applied in the field of separation and purification, can solve the problems of complicated procedures, long time, low efficiency, etc., and achieve the effect of simplifying the preparation process, realizing adsorption and desorption, and efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of polymer carrier

[0034] Dissolve 0.5 mol of DEAEM and 100 mL of EGDMA in 500 mL of acetonitrile, oscillate and mix evenly, and after standing in the dark for 10 minutes, add 3.77 g of initiator azobisisobutyronitrile, and oscillate evenly. Then, the mixed solution was ultrasonically degassed for 30 minutes, and then nitrogen gas was continuously passed in for 30 minutes. After vacuum sealing, it was placed in a water bath at 60° C. for 24 hours.

[0035] The obtained massive polymer was ground, pulverized, and sieved to obtain particles with a size of 100 mesh and 80 mesh. The above particles were wrapped with filter paper, placed in a Soxhlet extractor, and 80% methanol prepared in advance was added: 20 % acetic acid (v / v) extract, extract at 90°C for 24 hours to remove the porogen acetonitrile; then use 100% methanol to continue the extraction for 2 hours to remove acetic acid. The obtained polymer particles were dried under reduced ...

Embodiment 2

[0037] Embodiment 2: the preparation of polymer carrier

[0038] Shake and mix 1mol of DEAEM, 200mL of EGDMA and 1000mL of DMSO evenly. After standing in the dark for 10 minutes, add 7.54g of initiator azobisisobutyronitrile. After shaking evenly, ultrasonic degassing for 30 minutes, followed by nitrogen gas for 30 minutes , vacuum-sealed and placed in a 70°C water bath for 24 hours.

[0039] The block polymer obtained is ground, pulverized, sieved to obtain 100 mesh and 80 mesh size particles, the above particles are wrapped with filter paper, placed in a Soxhlet extractor, add 80% methanol: 20% acetic acid (v / v) extract at 90°C for 36h to remove the porogen DMSO, then use 100% methanol to continue the extraction for 3h, and finally dry the obtained polymer particles at 60°C under reduced pressure for 24h, Polymer carrier particles are obtained.

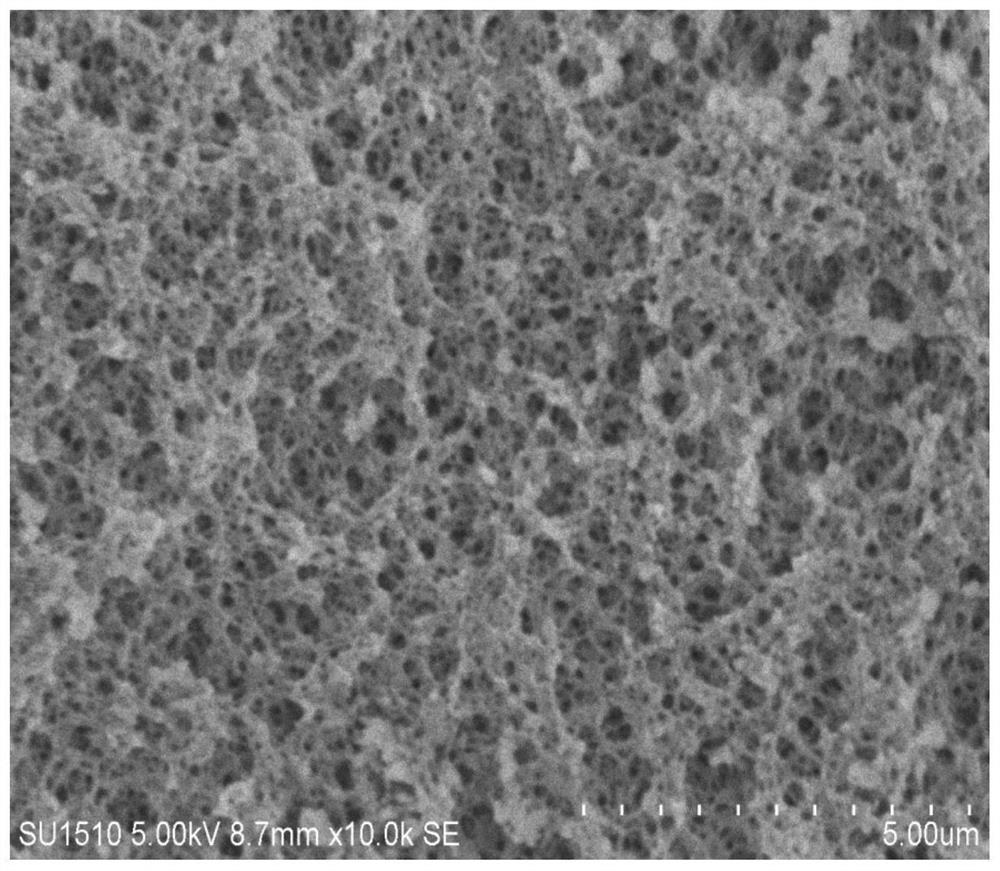

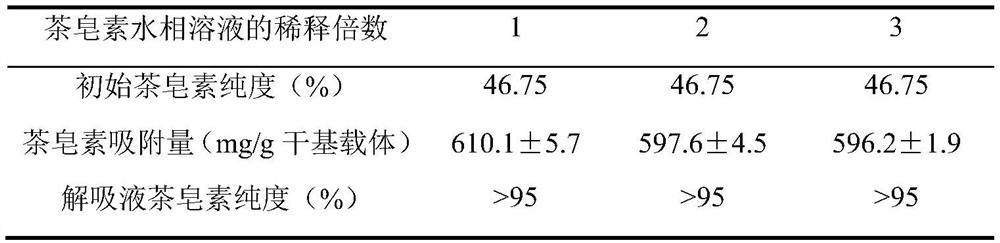

[0040] The obtained polymer carrier particles were scanned by scanning electron microscope; the obtained particles were measure...

Embodiment 3

[0041] Embodiment 3: the preparation of polymer carrier

[0042] Shake and mix 1mol of DEAEM, 200mL of EGDMA and 5000mL of DMSO evenly, add 7.54g of initiator azobisisobutyronitrile, shake evenly, degas with ultrasonic for 30min, then continue to pass in nitrogen for 30min, vacuum seal and place in water bath In a shaker, shake at 150r / min at 60°C for 24h.

[0043] The obtained granular precipitate was wrapped with filter paper, placed in a Soxhlet extractor, added with 80% methanol: 20% acetic acid (v / v) extract, and extracted at 90°C for 36h to remove the porogen DMSO, Then 100% methanol was used to continue the extraction for 3 hours, and finally the obtained polymer particles were dried under reduced pressure at 60° C. for 24 hours to obtain polymer carrier particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com