Preparation method of organic silicon modified polyurethane hot melt adhesive

A polyurethane hot-melt adhesive and modified polyester technology, applied in the field of structural adhesives, can solve the problems of reducing the solvent resistance and aging resistance of polyurethane hot-melt adhesive coatings, so as to improve compatibility and improve aging resistance. performance, the effect of improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

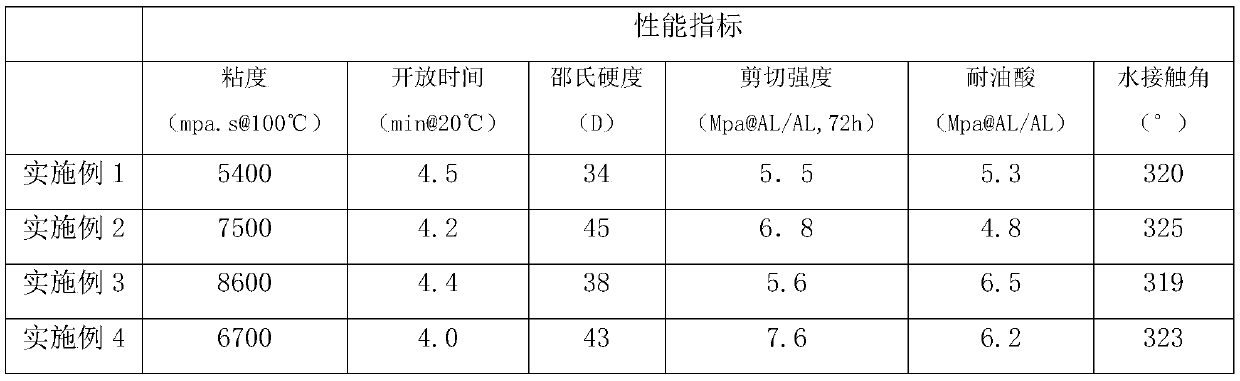

Examples

Embodiment 1

[0021] (1) Put 10 parts of dimethyldimethoxysilane, 10 parts of methylphenyldimethoxysilane, and 10 parts of diphenyldimethoxysilane into the three-necked upper bottle, and add Lewatit S -100, heat up to 40°C for 2 hours, then stir 20 parts of HJ-0511 evenly, heat up to 100°C, react for 4 hours, filter while hot to obtain a block copolymer of silicone-modified polyester polyol;

[0022] (2) 20 parts of Evonik 7360, 50 parts of the silicone-modified polyester polyol block copolymer synthesized in step (1), heated to 100°C, vacuumed to remove water for about 3 hours, and cooled to 50°C , under the protection of nitrogen, add 10 parts of isocyanate MDI, carry out polymerization reaction for 2 hours, and then add 0.1 part of triethanolamine to obtain silicone-modified polyurethane hot melt adhesive.

Embodiment 2

[0024] (1) Put 20 parts of dimethyldimethoxysilane, 20 parts of methylphenyldimethoxysilane, and 20 parts of diphenyldimethoxysilane into the three-necked upper bottle, and add Lewatit S -100, heat up to 60°C for 2 hours, then stir 40 parts of HJ-R380 evenly, heat up to 120°C, react for 6 hours, and filter while hot to obtain a block copolymer of silicone-modified polyester polyol;

[0025] (2) 30 parts of Evonik 7380, 70 parts of the silicone-modified polyester polyol block copolymer synthesized in step (1), heated at 120°C, vacuumed to remove water for about 5 hours, and cooled to 70°C , under the protection of nitrogen, add 30 parts of isocyanate MDI, carry out polymerization reaction for 6 hours, and then add 2 parts of triethanolamine to obtain silicone-modified polyurethane hot melt adhesive.

Embodiment 3

[0027] (1) Add 15 parts of dimethyldimethoxysilane, 15 parts of methylphenyldimethoxysilane, and 115 parts of diphenyldimethoxysilane into the three-necked upper bottle, and add Lewatit S -100, heat up to 60°C for 2 hours, then stir 35 parts of HJ-7380H evenly, heat up to 100°C, react for 6 hours, filter while hot to obtain a block copolymer of silicone-modified polyester polyol;

[0028] (2) 10 parts of Evonik 7360+10 parts of Evonik 7380, 60 parts of the block copolymer of silicone-modified polyester polyol synthesized in step (1), heated at 120°C, and vacuumed to remove water for about 5 Hours, the temperature was lowered to 70°C, under the protection of nitrogen, 25 parts of isocyanate MDI was added, and the polymerization reaction was carried out for 3 hours, and then 1 part of 2,2-dimorpholinyl was added to obtain a silicone-modified polyurethane hot melt adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com