Method for extracting and purifying polyhydroxyalkanoate

A technology of polyhydroxyalkanoate and microbial bacteria, which is applied in the downstream post-processing field of bioengineering, can solve the problems of complicated extraction steps, high cost of chemical substances, difficult downstream sewage treatment, etc., achieve simple and safe production environment, reduce extraction cost, The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Superheated water method extracts and purifies PHA from the fermented liquid containing PHA thalline

[0050] method of extraction:

[0051] (1) Centrifugation and resuspension of bacteria for desalting

[0052] Halomonas containing 60% PHA (P3HB, P34HB can be) 1 250mL of the fermentation broth of the bacteria was placed symmetrically in a high-speed centrifuge after balancing, and the centrifugation conditions were: speed 6000rpm, time 20min. After the centrifugation, carefully remove the supernatant, pay attention not to lose the precipitate as much as possible, then add water to restore the volume, stir well and continue centrifuging, the centrifugation conditions are: 6000rpm, time 20min. After centrifugation, discard the supernatant, restore the volume of the bacteria to 250mL, stir evenly, pour the washed bacteria solution into a 500mL beaker, and prepare to break the wall.

[0053] (2) Cell wall breaking and PHA release of bacterial liquid

[00...

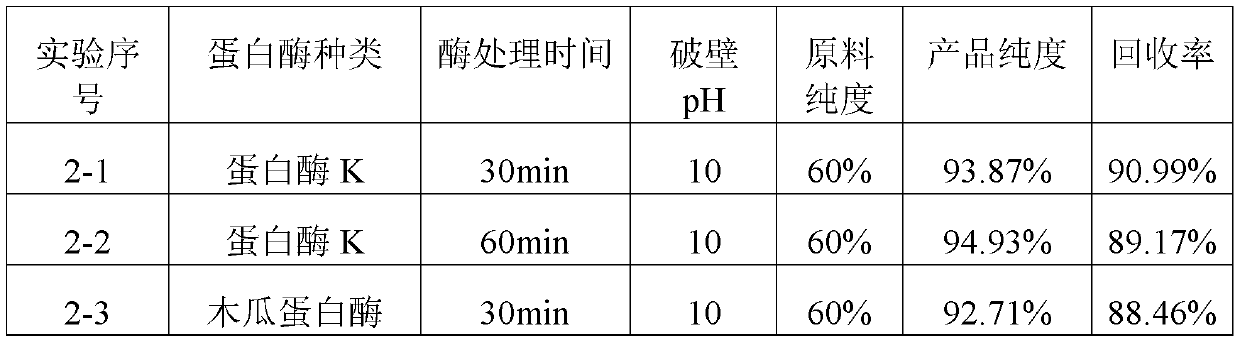

Embodiment 2

[0061] Embodiment 2: Superheated water protease method extracts and purifies PHA from the fermented liquid containing PHA thallus

[0062] method of extraction:

[0063] (1) Centrifugation and resuspension of bacteria for desalting

[0064] Halomonas containing 60% PHA (P3HB, P34HB can be) 1 250mL of the fermentation broth of the bacteria was placed symmetrically in a high-speed centrifuge after balancing, and the centrifugation conditions were: speed 6000rpm, time 20min. After the centrifugation, carefully remove the supernatant, pay attention not to lose the precipitate as much as possible, then add water to restore the volume, stir well and continue centrifuging, the centrifugation conditions are: 6000rpm, time 20min. After centrifugation, discard the supernatant, restore the volume of the bacteria to 250mL, stir evenly, pour the washed bacteria solution into a 500mL beaker, and prepare to break the wall.

[0065] (2) Cell wall breaking and PHA release of bacterial liqui...

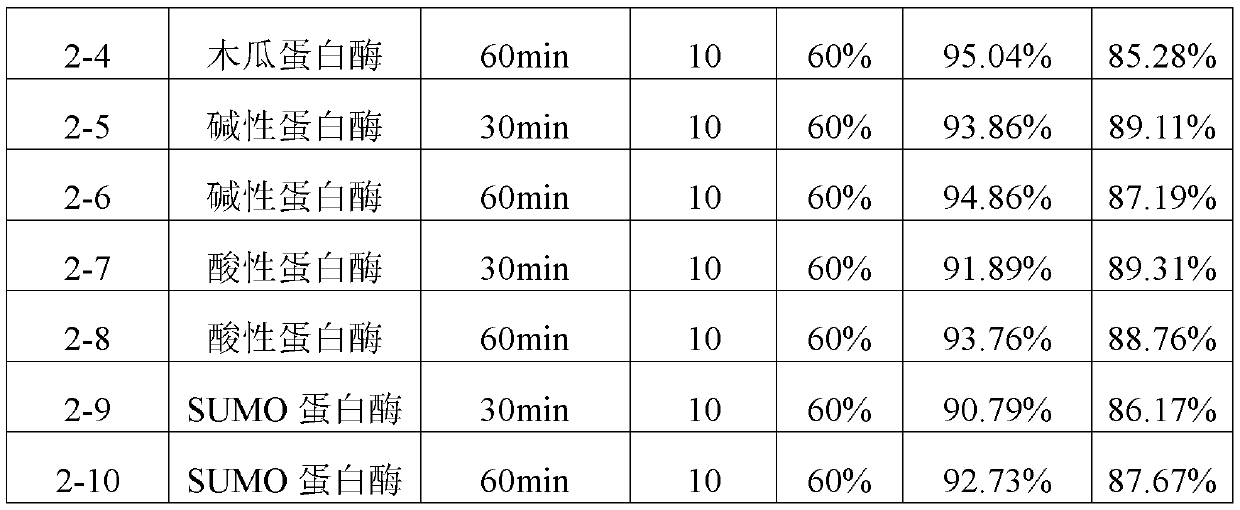

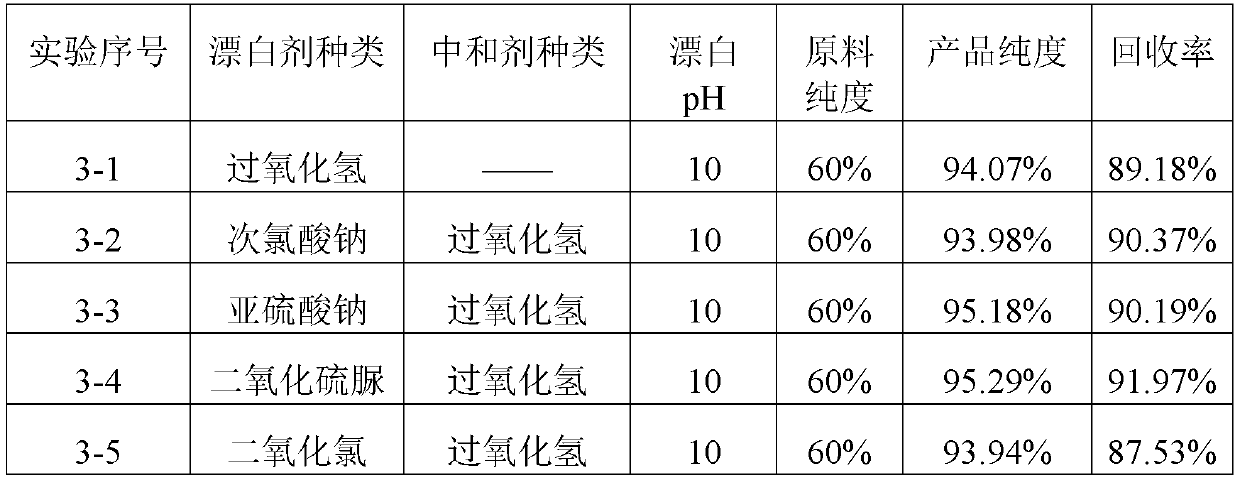

Embodiment 3

[0077] Embodiment 3: superheated water, protease plus bleach method extract and purify PHA from the fermented liquid containing PHA thallus

[0078] method of extraction:

[0079] (1) Centrifugation and resuspension of bacteria for desalting

[0080] Halomonas containing 60% PHA (P3HB, P34HB can be) 1 250mL of the fermentation broth of the bacteria was placed symmetrically in a high-speed centrifuge after balancing, and the centrifugation conditions were: speed 6000rpm, time 20min. After the centrifugation, carefully remove the supernatant, pay attention not to lose the precipitate as much as possible, then add water to restore the volume, stir well and continue centrifuging, the centrifugation conditions are: 6000rpm, time 20min. After centrifugation, discard the supernatant, restore the volume of the bacteria to 250mL, stir evenly, pour the washed bacteria solution into a 500mL beaker, and prepare to break the wall.

[0081] (2) Cell wall breaking and PHA release of bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com