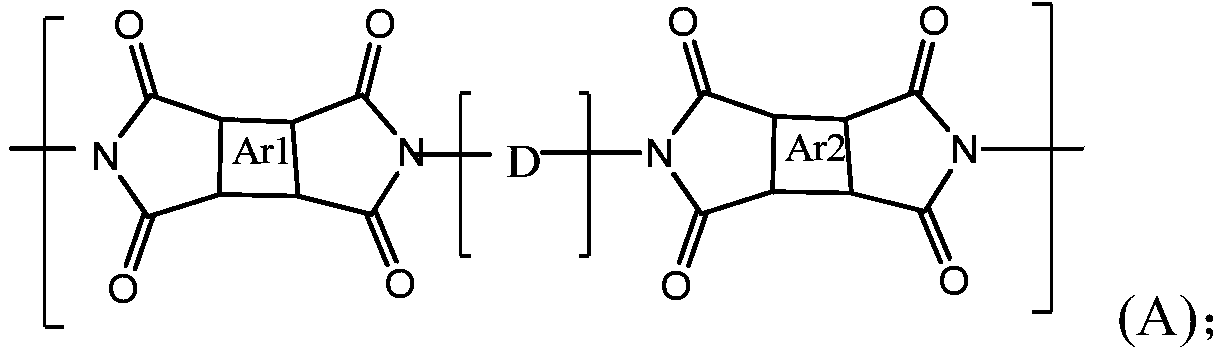

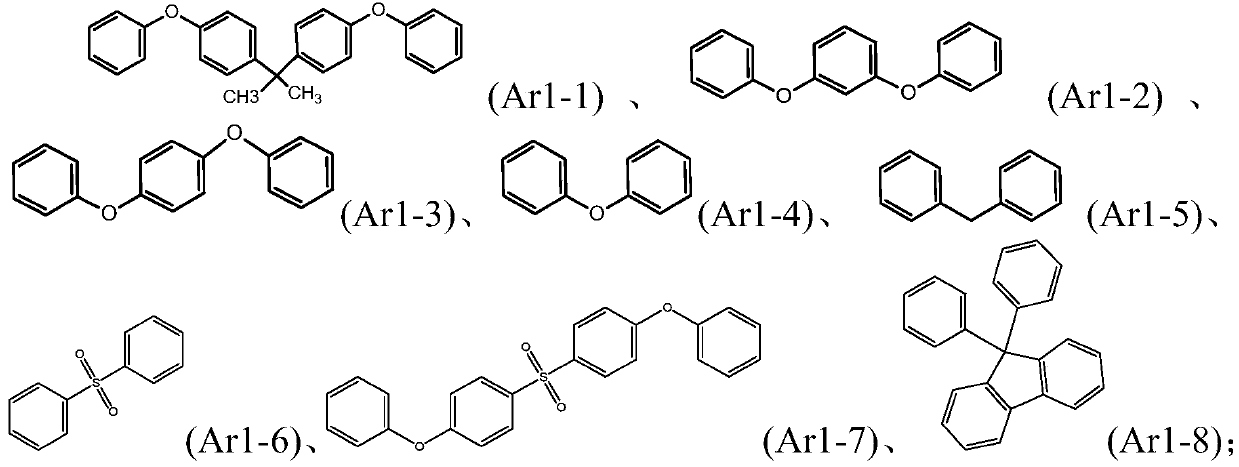

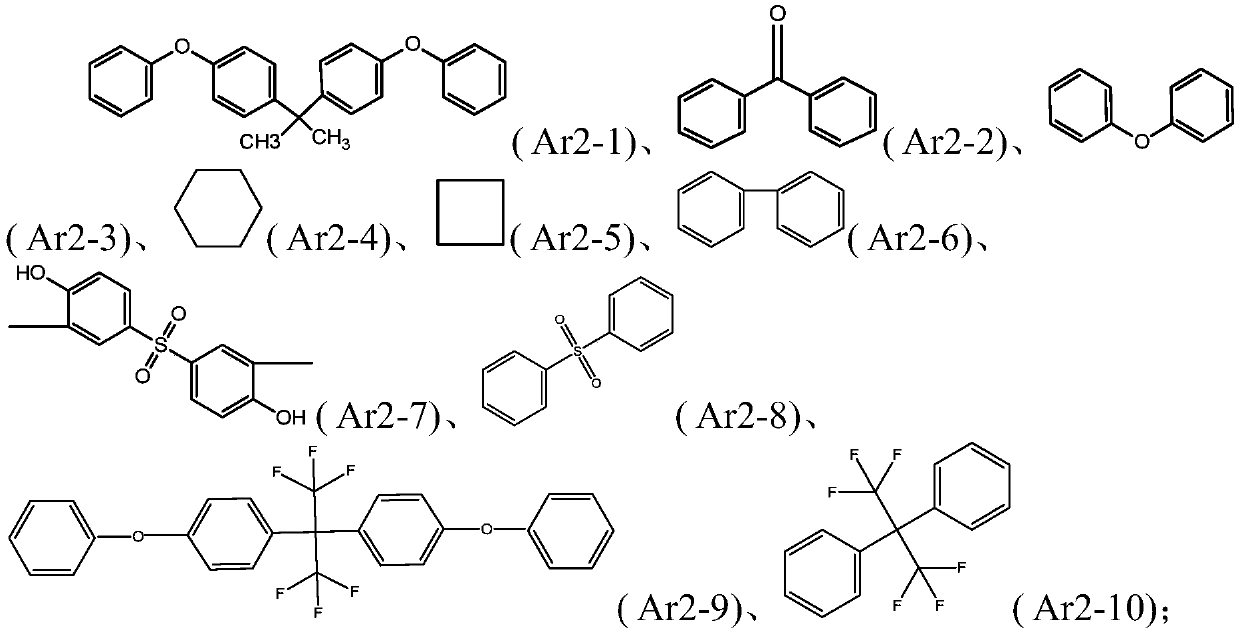

Soluble polyimide resin powder with low thermal expansion coefficient, and preparation method thereof

A low thermal expansion coefficient, polyimide resin technology, applied in the direction of coating, etc., can solve the problems of insufficient processability, insufficient rigidity of soluble polyimide, etc., to improve solvent solubility, increase spacing, reduce The effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The specific preparation method is:

[0049] 1) Steps for preparing a low thermal expansion coefficient soluble polyamic acid resin solution:

[0050] The first step: Take 27.293 parts of TFDB and 250 parts of aprotic polar solvent N,N-dimethylformamide in a three-necked flask with an electric stirrer, stir until completely dissolved, add 12.394 parts of PMDA monomer, Stirring and reacting for 2h to obtain a block polyamic acid resin solution for subsequent use; wherein, in the system, TFDB is excessive relative to the PMDA monomer, and the number of repeating structural units in the obtained block polyamic acid resin solution is 2;

[0051] Step 2: Add 39.81 parts of 3,4-ODA and 600 parts of aprotic polar solvent N,N-dimethylformamide to the obtained block polyamic acid resin solution, stir until the monomers are completely dissolved, and then add 70.503 1 part of ODPA monomer (added in 3 times), stirred and reacted for 4h to obtain a soluble polyamic acid resin solut...

Embodiment 2

[0056] The specific preparation method is:

[0057] 1) Steps for preparing a low thermal expansion coefficient soluble polyamic acid resin solution:

[0058] The first step: Take 59.901 parts of TFDB and 250 parts of aprotic polar solvent DMAc in a three-necked flask with an electric stirrer, stir until completely dissolved, add 34.0 parts of PMDA monomer, and stir for 2 hours to obtain a block polymer Amic acid resin solution, standby; Wherein, in the system, TFDB is excessive relative to PMDA monomer, and the number of repeating structural units in the gained block polyamic acid resin solution is 5;

[0059] The second step: add 24.963 parts of 3,4-ODA and 550 parts of aprotic polar solvent DMAc to the obtained block polyamic acid resin solution, stir until the monomer is completely dissolved, then add 81.135 parts of BPADA monomer (in 3 times Add), stir and react for 4 hours to obtain a soluble polyamic acid resin solution with a low thermal expansion coefficient, the visc...

Embodiment 3

[0064] The specific preparation method is:

[0065] 1) Steps for preparing a low thermal expansion coefficient soluble polyamic acid resin solution:

[0066] Step 1: Take 13.702 parts of TFDB and 250 parts of aprotic polar solvent NMP in a three-necked flask with an electric stirrer, stir until completely dissolved, add 8.711 parts of PMDA monomer, and stir for 2 hours to obtain a block polyamide Acid resin solution, standby; Wherein, in the system, TFDB is excessive relative to PMDA monomer, and the number of repeating structural units in the gained block polyamic acid resin solution is 12;

[0067]The second step: add 48.538 parts of 3,4-ODA and 600 parts of aprotic polar solvent NMP to the obtained block polyamic acid resin solution, stir until the monomer is completely dissolved, then add 79.049 parts of BTDA monomer (in 3 times Add), stir and react for 4 hours to obtain a soluble polyamic acid resin solution with a low thermal expansion coefficient, the viscosity is 12,0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com