A process for cleaning the inner cover of bell annealing furnace

A bell-type annealing furnace and annealing furnace technology are applied to the improvement of process efficiency, furnaces, manufacturing tools and other directions, which can solve the problems of reduced annealing efficiency, carburizing of inner hood walls, and increased energy consumption, and achieve the effect of improving annealing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

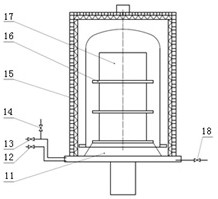

[0023] In this example, refer to the attached figure 1 , the first step is to load convection trays or steel scrap coils with a stacking height of more than half or the entire furnace on a fault-free annealing furnace table, fasten the inner cover and heating cover, and press nitrogen to the pressure of about 50MPa in the furnace for sealing Inspection, after the seal inspection is passed, fill the nitrogen purging furnace with a flow rate of 120m³ / h for one hour, and heat it to 450°C at a rate of 150°C / h under the premise of ensuring a furnace pressure of about 50MPa, and start to keep warm, and at the same time keep warm at a temperature of 20m³ / h Fill the compressed air at a flow rate of h, turn off the compressed air after 5 hours of heat preservation, fill the air in the furnace with nitrogen at a flow rate of 120m³ / h, and finally cool down normally in the nitrogen mode and leave the furnace;

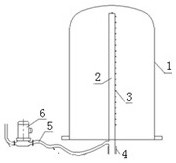

[0024] Refer to attached figure 2 In the second step, use high-pressure fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com