Comprehensive sintering method of large-proportion limonite

A sintering method and large-scale technology, which are applied in the field of powder ore sintering metallurgy and the comprehensive sintering field of large-scale limonite, which can solve problems such as easy bonding into agglomerates, low sinter strength and yield, and low limonite assimilation temperature. problems, to achieve the effect of increasing production, reducing costs, and improving balling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

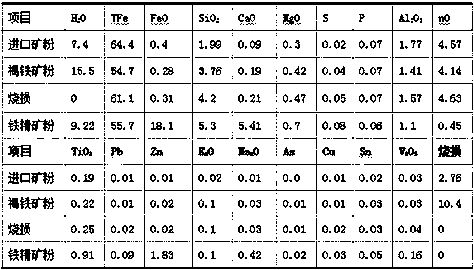

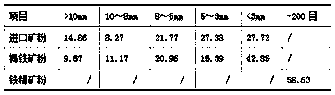

Image

Examples

Embodiment 1

[0034] A comprehensive sintering method for a large proportion of limonite, the method is completed through the following steps:

[0035] 1) According to the following mass ratio ingredients:

[0036] Limonite Powder 60%

[0037] Imported mineral powder 10%

[0038] Iron Concentrate Powder 5%

[0039] Dolomite 3.0%

[0040] Limestone 5.5%

[0041] Quicklime 3.5%

[0042] Coke powder 5.0%

[0043] Sinter under sieve powder 8%

[0044] Alkalinity control is 2;

[0045] 2) Mix the materials in step 1) once, and control the water content of the mixture to 5.0%;

[0046] 3) Perform secondary mixing of the mixture in step 2), and control the water content of the mixture to 9.5%;

[0047] 4) Put the mixed material in step 3) into the distributor of the sintering machine, first lay a base material with a thickness of 20mm, and then lay a sintered material layer with a thickness of 730mm, and press the material on the edges of both sides of the sintering machine, and at the sa...

Embodiment 2

[0051] A comprehensive sintering method for a large proportion of limonite, the method is completed through the following steps:

[0052] 1) According to the following mass ratio ingredients:

[0053] Limonite Powder 75%

[0054] Imported mineral powder 5%

[0055] Iron Concentrate Powder 5%

[0056] Dolomite 2%

[0057] Limestone 2%

[0058] Quicklime 3%

[0059] Coke powder 5%

[0060] Sinter under sieve powder 3%

[0061] Alkalinity control is 1.6;

[0062] 2) Mix the materials in step 1) once, and control the water content of the mixture to 8.5%;

[0063] 3) Perform secondary mixing of the mixture in step 2), and control the water content of the mixture to 6.5%;

[0064] 4) Put the mixed material in step 3) into the sintering machine distributor, first lay a base material with a thickness of 20mm, and then lay a sintered material layer with a thickness of 860mm, and press the material on both sides of the sintering machine, and at the same time The material is sp...

Embodiment 3

[0068] A comprehensive sintering method for a large proportion of limonite, the method is completed through the following steps:

[0069] 1) According to the following mass ratio ingredients:

[0070] Limonite Powder 70%

[0071] Imported mineral powder 6%

[0072] Iron Concentrate Powder 6%

[0073] Dolomite 3%

[0074] Limestone 4%

[0075] Quicklime 4%

[0076] Coke powder 6%

[0077] Sinter under sieve powder 1%

[0078] Alkalinity control is 1.8;

[0079] 2) Mix the materials in step 1) once, and control the water content of the mixture to 7.0%;

[0080] 3) Perform secondary mixing of the mixture in step 2), and control the water content of the mixture to 8.5%;

[0081] 4) Put the mixed material in step 3) into the distributor of the sintering machine, first lay a base material with a thickness of 20mm, and then lay a layer of sintered material with a thickness of 780mm, and press the material on both sides of the sintering machine, and at the same time The mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com