Coated PC composite board and manufacturing process thereof

A technology of composite board and first niobium oxide, which is applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of high cost, low production capacity, high requirements of coating process, etc., and achieve optimal attachment Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

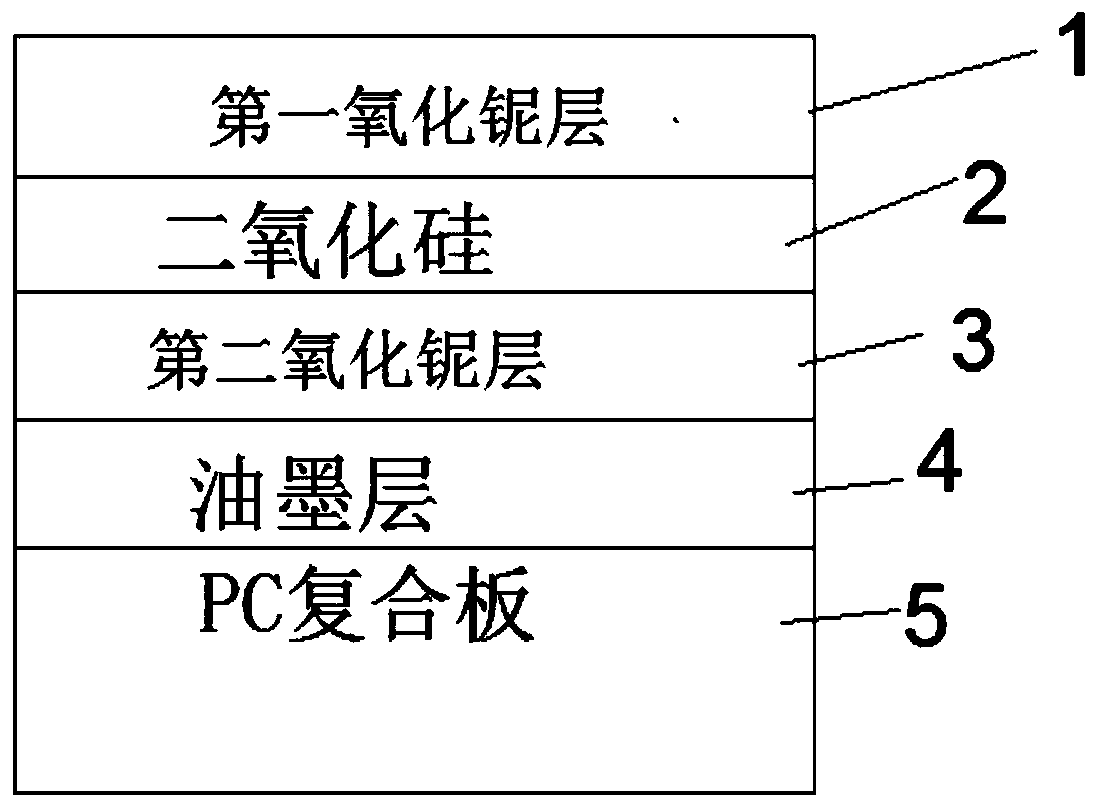

[0019] A coated PC composite board comprises, from top to bottom, a first niobium oxide layer, a silicon dioxide layer, a second niobium oxide layer, an ink layer and a PC composite board.

[0020] Further, the thickness of the first niobium oxide layer is 58nm.

[0021] Further, the thickness of the silicon dioxide layer is 25nm.

[0022] Further, the thickness of the second niobium oxide layer is 38nm.

[0023] A kind of preparation technology of the PC composite board of described coating comprises the following processing steps:

[0024] Step 1: Install the niobium oxide target and silicon dioxide target in the coating box, close the box, raise the temperature to 250°C, bake the coating box for 1.5 hours, and continuously vacuumize the box to remove the Water vapor and miscellaneous gases;

[0025] Step 2, wait until the local vacuum reaches 5×10 -4 Pa, filled with argon and oxygen with a purity of 99.99%, so that the working pressure reaches 0.5Pa;

[0026] Step 3, t...

Embodiment 2

[0028] A coated PC composite board comprises, from top to bottom, a first niobium oxide layer, a silicon dioxide layer, a second niobium oxide layer, an ink layer and a PC composite board.

[0029] Further, the thickness of the first niobium oxide layer is 53nm.

[0030] Further, the thickness of the silicon dioxide layer is 23nm.

[0031] Further, the thickness of the second niobium oxide layer is 35nm.

[0032] A kind of preparation technology of the PC composite board of described coating comprises the following processing steps:

[0033] Step 1: Install the niobium oxide target and silicon dioxide target in the coating box, close the box, raise the temperature to 280°C, bake the coating box for 1 hour, and continuously vacuum to remove the water in the box steam and fumes;

[0034] Step 2, wait until the local vacuum reaches 5×10 -4 Pa, filled with argon and oxygen with a purity of 99.99%, so that the working pressure reaches 0.6Pa;

[0035] Step 3, turn on the ion so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com