Composite blade and compressor blade diffuser

A technology of compressor blades and diffusers, which is applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems of large airflow impact loss, unstable working conditions, separation, etc., to reduce airflow obstruction, Improve flow conditions and improve the effect of flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

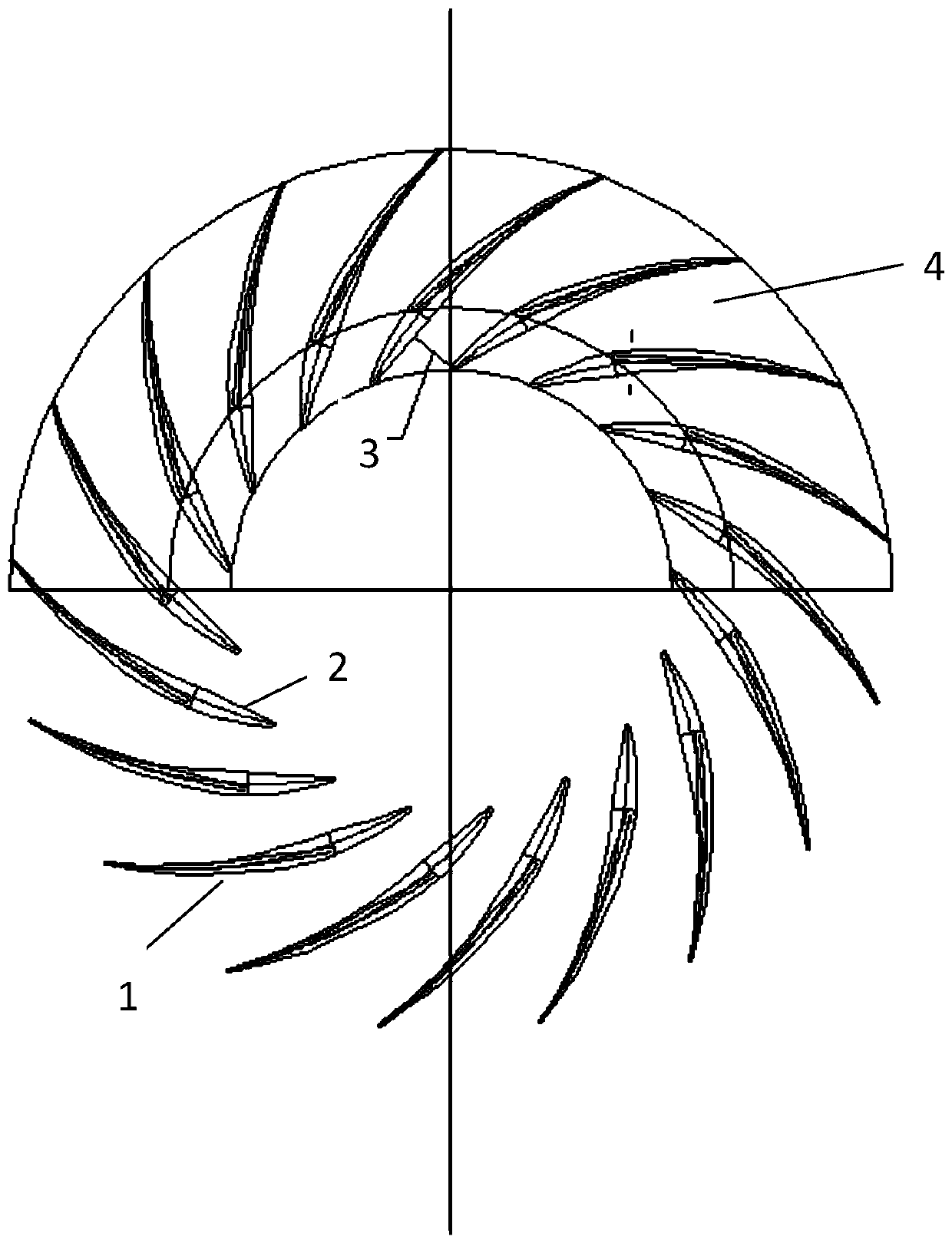

[0032] Such as figure 1 As shown, the present invention provides a vane diffuser, the vane diffuser is composed of two sections of airfoil-shaped composite blades, and the circumference is evenly distributed in the flow channel of the diffuser body 4 to form two sections of composite airfoil-shaped blades Diffuser form.

[0033] Further, the blade is a two-section airfoil blade as a whole, the front section blade 1 adopts a half-height blade and the rear section blade 2 is a composite airfoil blade with a full height blade, and the joint position of the front and rear sections is at the throat of the diffuser channel After 3, the rear half of the airfoil blade head adopts a new airfoil design, which solves the limitation that the number of blade airfoils is difficult to arrange reasonably, and has the advantage of high efficiency and low cost.

[0034] Furthermore, the half-height section of the blade head of the composite airfoil diffuser can be installed on the disk side or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com