Liquid metal pressure information measuring device and system

A technology of liquid metal and pressure information, which is used in measuring devices, elastic deformation gauge-type fluid pressure measurement, and fluid pressure measurement. and other problems, to achieve the effect of simple and reliable measurement process, simple and reliable measurement system, and large measurement pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

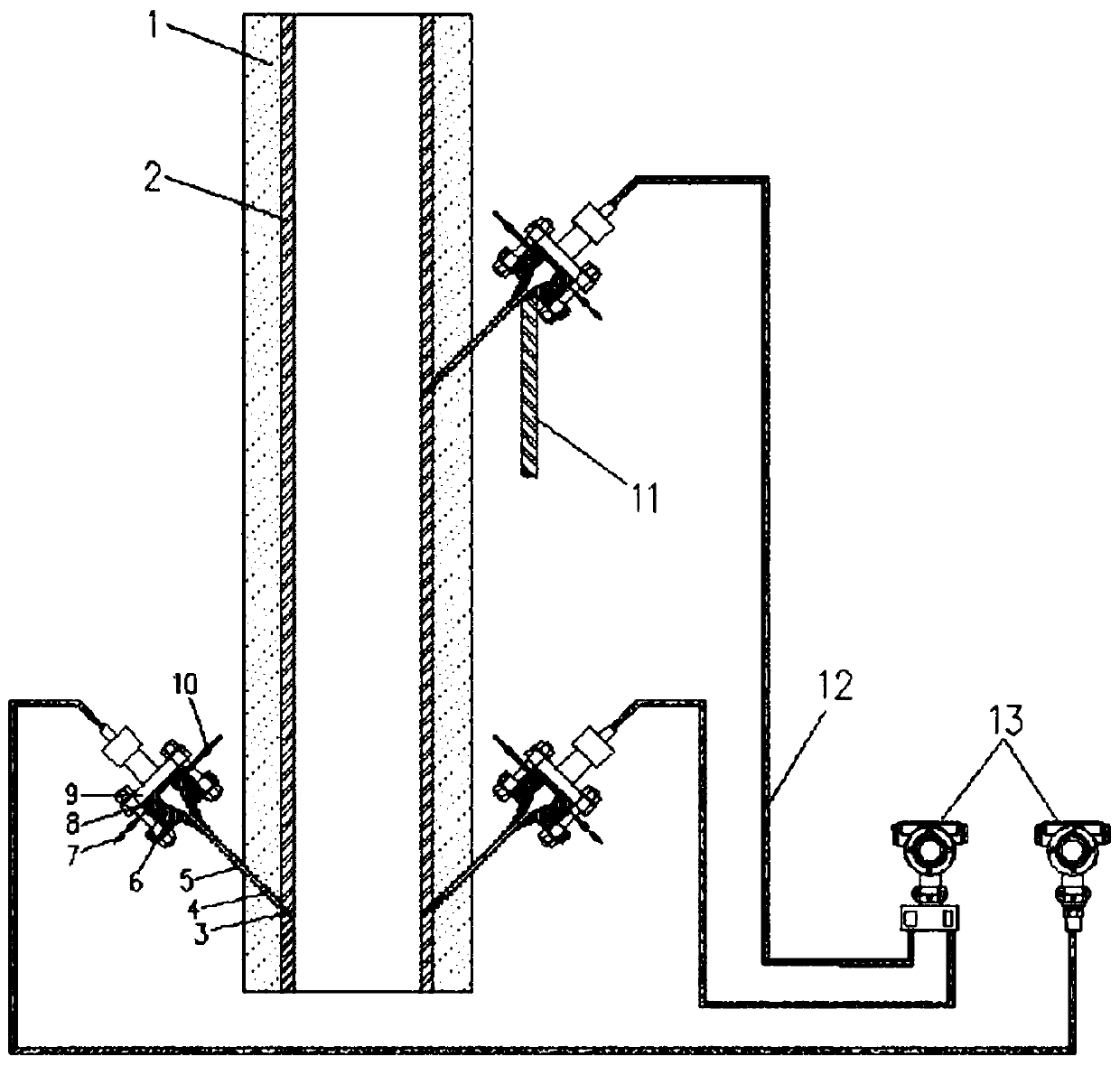

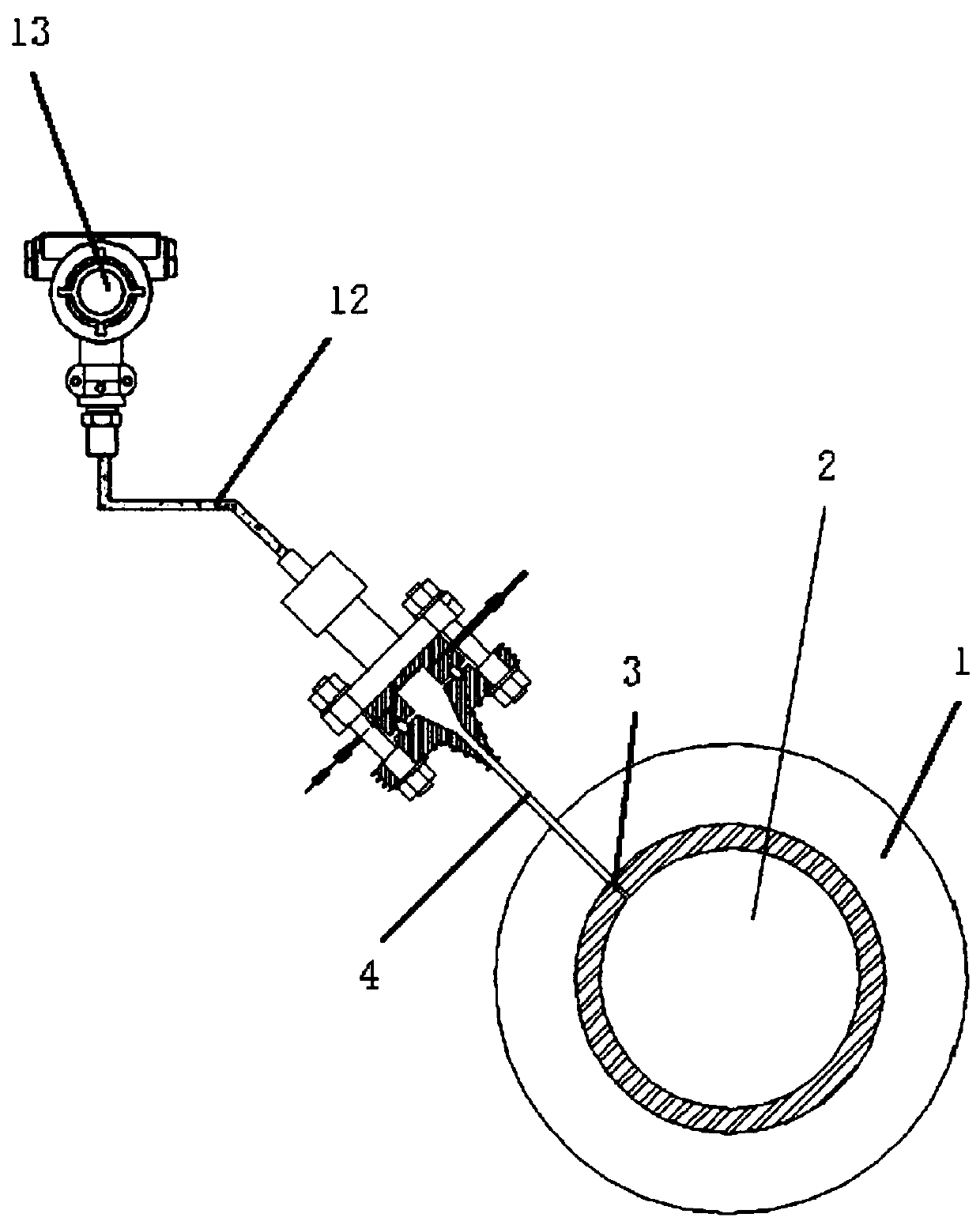

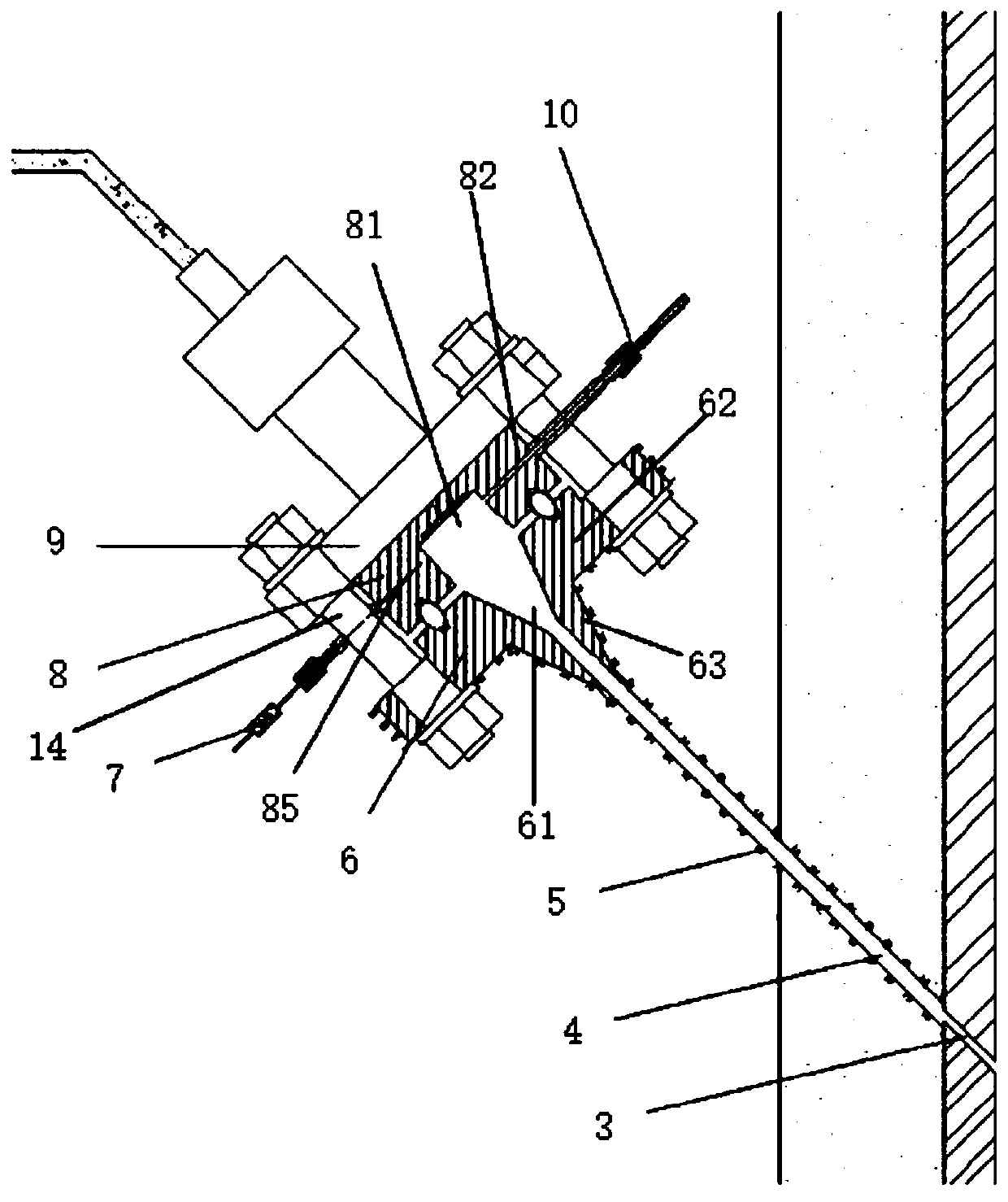

[0022] see Figure 1 to Figure 3 , the invention discloses a liquid metal pressure information measuring device, comprising a pressure information sensor 13, a pressure guiding tube 12, a sensor side mounting part 9 (with a measuring diaphragm inside), a sealing diaphragm box 8, and a pressure guiding tube side mounting part 6 and the pressure guide tube 4, one end of the pressure guide tube 12 is connected to the pressure information sensor 13, and the other end of the pressure guide tube 12 is connected to the sensor side mounting part 9, and the sensor side mounting part 9 and the pressure guiding tube side mounting part 6 pass through the tight The firmware 14 is fixedly connected, and the sealing membrane box 8 is sealed and connected between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com