Three-cladding ytterbium-doped quartz optical fiber and high-concentration fluorine-layer quartz tube rod sleeving method

A silica fiber, high-concentration technology, applied in the direction of cladding fiber, multi-layer core/cladding fiber, glass fiber products, etc., can solve the problem of not completely solving the technical problems of triple-clad fiber, and achieve excellent anti-darkening performance, small non-linear effects, reduced use length effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

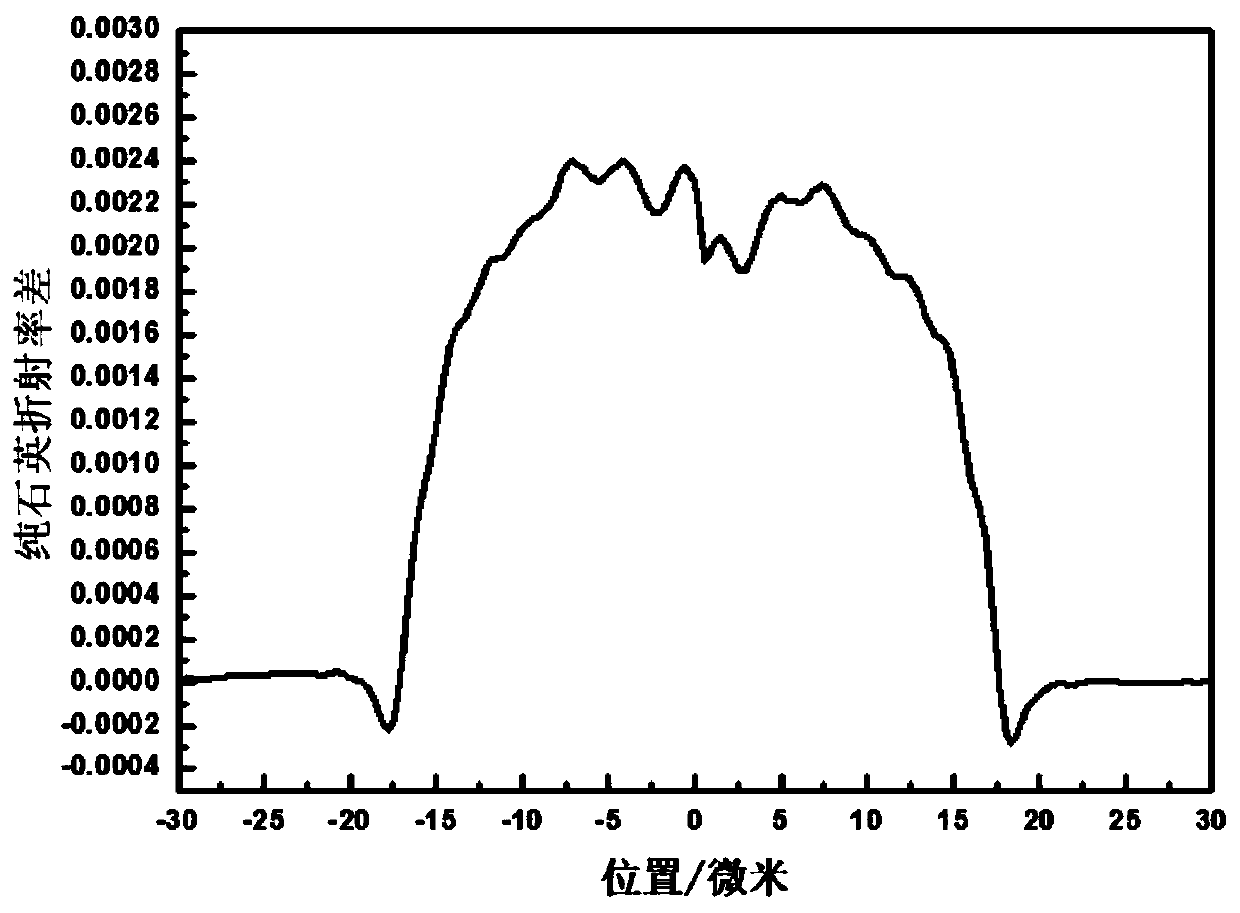

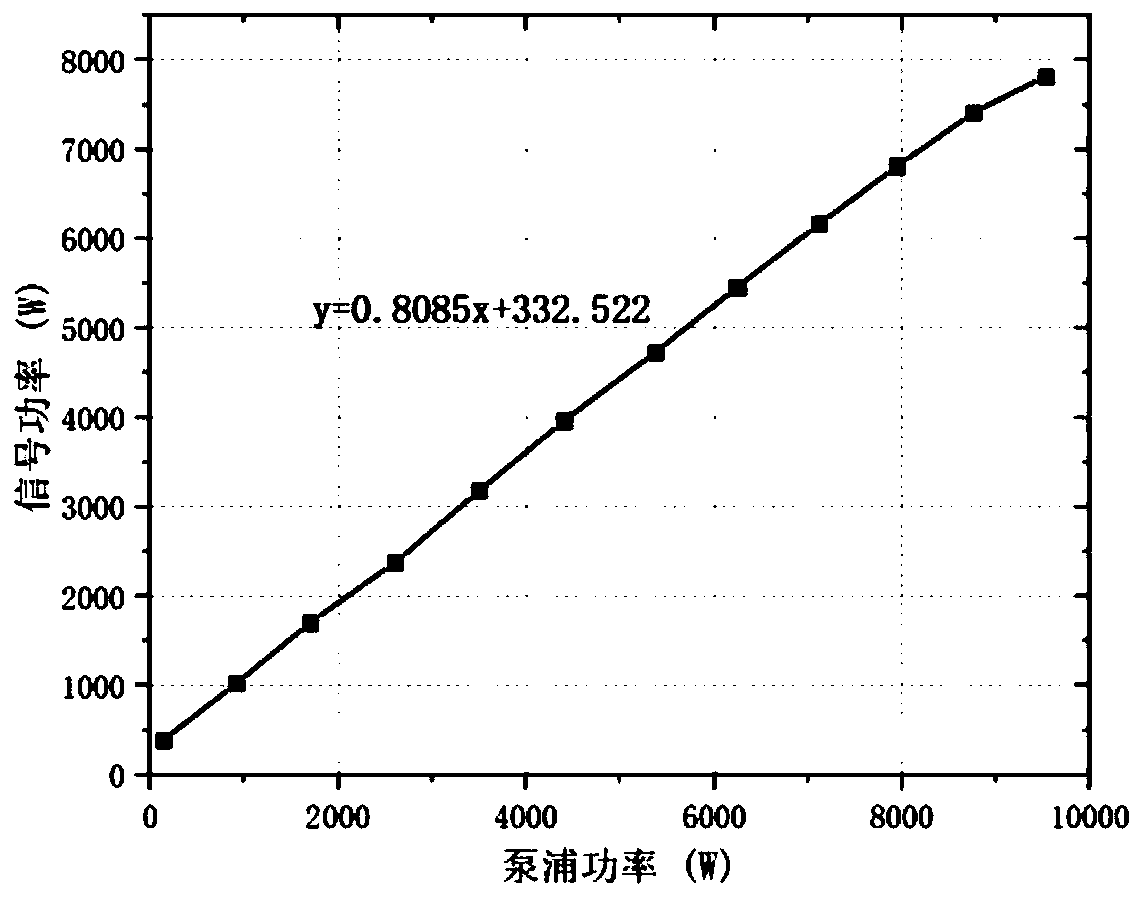

[0042] The triple-clad ytterbium-doped silica fiber core glass composition is: Yb 2 o 3 The doping concentration is 0.25mol%, Yb 2 o 3 : CeO 2 :Al 2 o 3 :P 2 o 5 =1:0.25:8.2:12.5 (mol ratio), the rest is SiO 2 . The outer cladding is a high-concentration fluorine layer quartz tube, and there is no air bubble between the high-concentration fluorine layer quartz tube and the pure quartz glass inner cladding.

[0043] The preparation process of the three-clad ytterbium-doped silica fiber core rod in this embodiment is consistent with the patent CN109502961A;

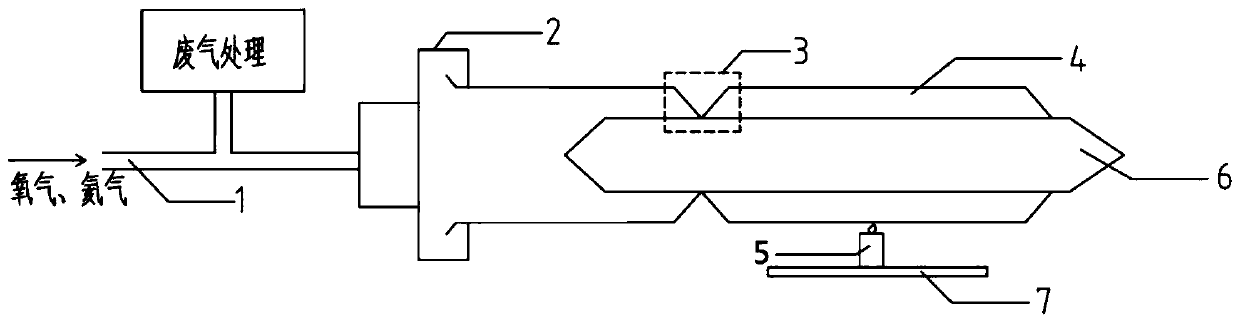

[0044] In this embodiment, the three-clad ytterbium-doped silica fiber core rod needs to be covered with a high-concentration fluorine layer quartz tube (the concentration of fluorine element is 35000ppm), and the numerical aperture between the high-concentration fluorine layer quartz tube and the quartz inner cladding is 0.21; The structure of the equipment used in the fluorine layer quartz tube sleeve rod method...

Embodiment 2

[0057] The triple-clad ytterbium-doped silica fiber core glass composition is: Yb 2 o 3 The doping concentration is 0.2mol%, Yb 2 o 3 : CeO 2 :Al 2 o 3 :P 2 o 5 =1:0.2:8.5:13 (mol ratio), the rest is SiO 2 . The outer cladding is a high-concentration fluorine layer quartz tube, and there is no air bubble between the high-concentration fluorine layer quartz tube and the pure quartz glass inner cladding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com