overcurrent protection device

A protection device and overcurrent technology, applied in the direction of circuits, resistors, electrical components, etc., can solve problems such as circuit protection device failures, and achieve the effect of low initial resistance and sufficient peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]

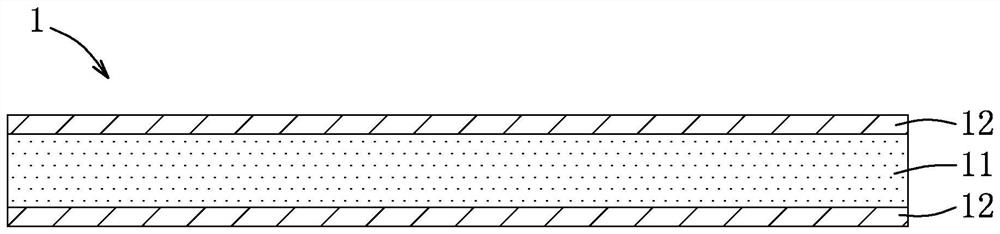

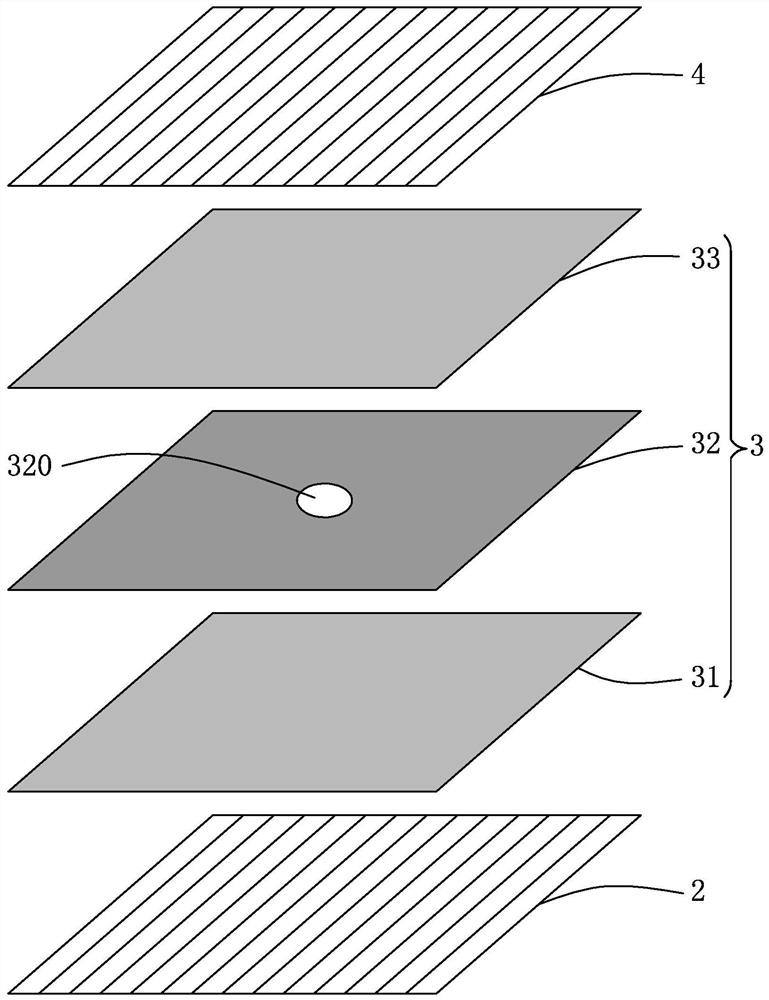

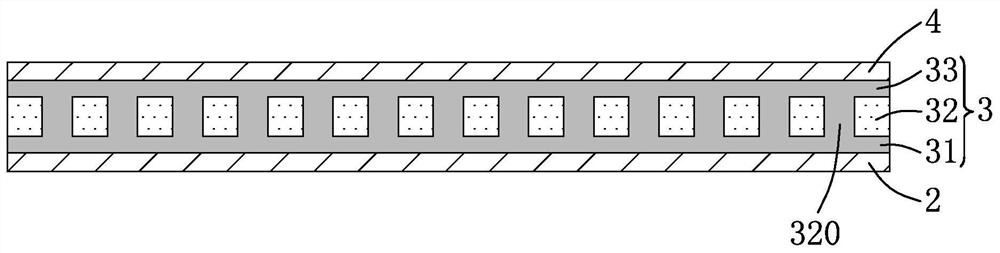

[0058] 10g HDPE (purchased from Taiwan Plastic Industry Co., Ltd., product model: HDPE9002) as non-grafted polyolefin, and 10 g of HDPE (MA-g-HDPE, purchased from DuPont, product model: MB100D ) as the polyolefin grafted with unsaturated carboxylic acid anhydride for the first polymer composition of the first polymer layer 31 and the third polymer composition of the third polymer layer 33 . 30g carbon black powder (purchased from Columbian Chemicals Co., product model: Raven430UB, DBP / D is 0.95, bulk density is 0.53g / cm 3 ) is used as the particulate conductive filler for the first polymer layer 31 and the third polymer layer 33. 20 g of HDPE (purchased from Taiwan Plastic Industry Co., Ltd., product model: HDPE9002) was used as the second polymer composition of the second polymer layer 32 . 30 g of carbon black powder (available from Columbian Chemicals Co., product model: Raven 430UB) was used as the granular conductive filler of the second polymer layer 32 . Th...

Embodiment 2 to 4

[0062]

[0063] The processing conditions of the test samples of embodiments 2 to 4 (E2-E4) are similar to those of embodiment 1, the difference is that the HDPE and MA-g-HDPE of the first polymer composition and the third polymer composition The usage amounts were changed as shown in Table 1.

Embodiment 5 to 8

[0064]

[0065] The processing conditions of the test samples of Examples 5 to 8 (E5-E8) are similar to those of Examples 1 to 4 in sequence, the difference lies in the stacking of the first polymer layer 31, the second polymer layer 32 and the first polymer layer 32. Before the three polymer layers 33, the second polymer layer 32 is formed with a plurality of perforations 320 (the diameter of each perforation is 1.0mm, and its area is 0.7854mm 2 ), and the perforation density is 9 holes / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com