A kind of current transformer production process and its production equipment

A technology for current transformers and production equipment, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of limited stirring range, poor stirring effect, and too fast stirring speed of the stirring paddle, so as to improve the stirring speed. Mixing effect, improving potting effect, smooth potting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

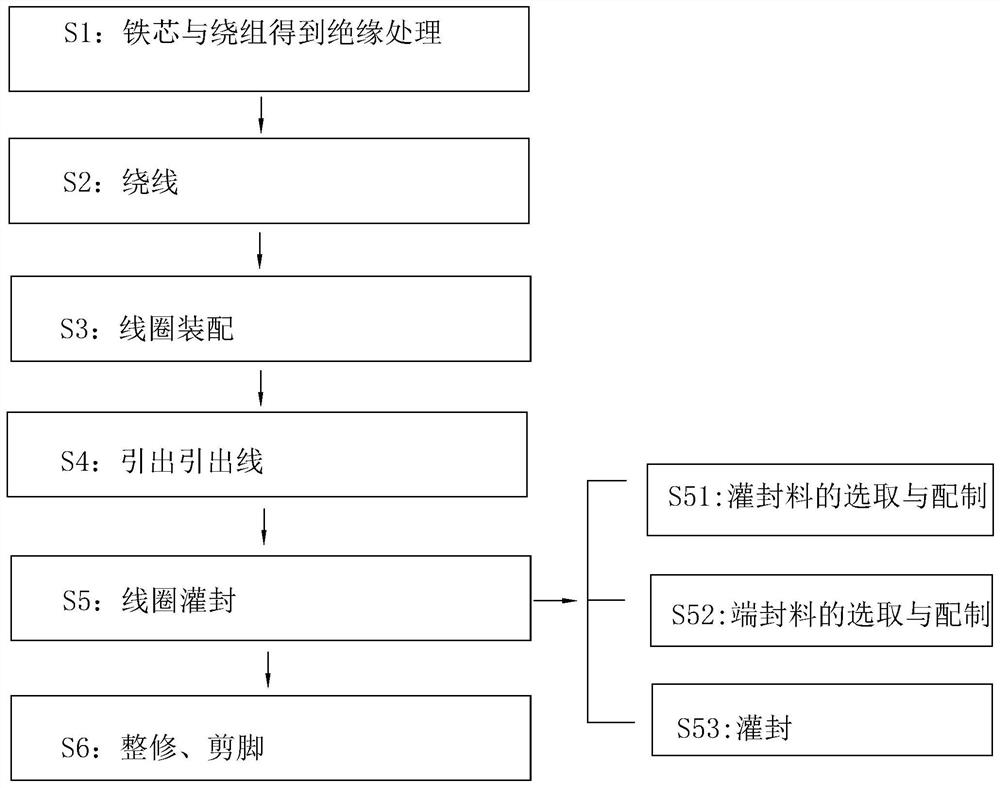

[0045] A kind of current transformer production process, with reference to figure 1 , including the following steps: S1: Insulation treatment of the iron core and the winding: wrapping the iron core with an insulating plastic shell, and wrapping the surface of the primary winding and the secondary winding with insulating tape;

[0046] S2: Winding: Winding the iron core. After the insulation of the iron core is completed, the primary winding is performed. After the primary winding is completed, the primary winding is wound with 0.08mm yellow wax silk. After the winding is completed, the secondary winding is performed to form a semi-finished current transformer. ;

[0047] S3: Coil assembly: Put the semi-finished transformer into the corresponding installation shell, and heat it with the tip of the electric soldering iron, so that the semi-finished transformer is fixedly connected to the installation shell.

[0048] S4: Lead-out lead-out line: lead the winding wire directly th...

Embodiment 2

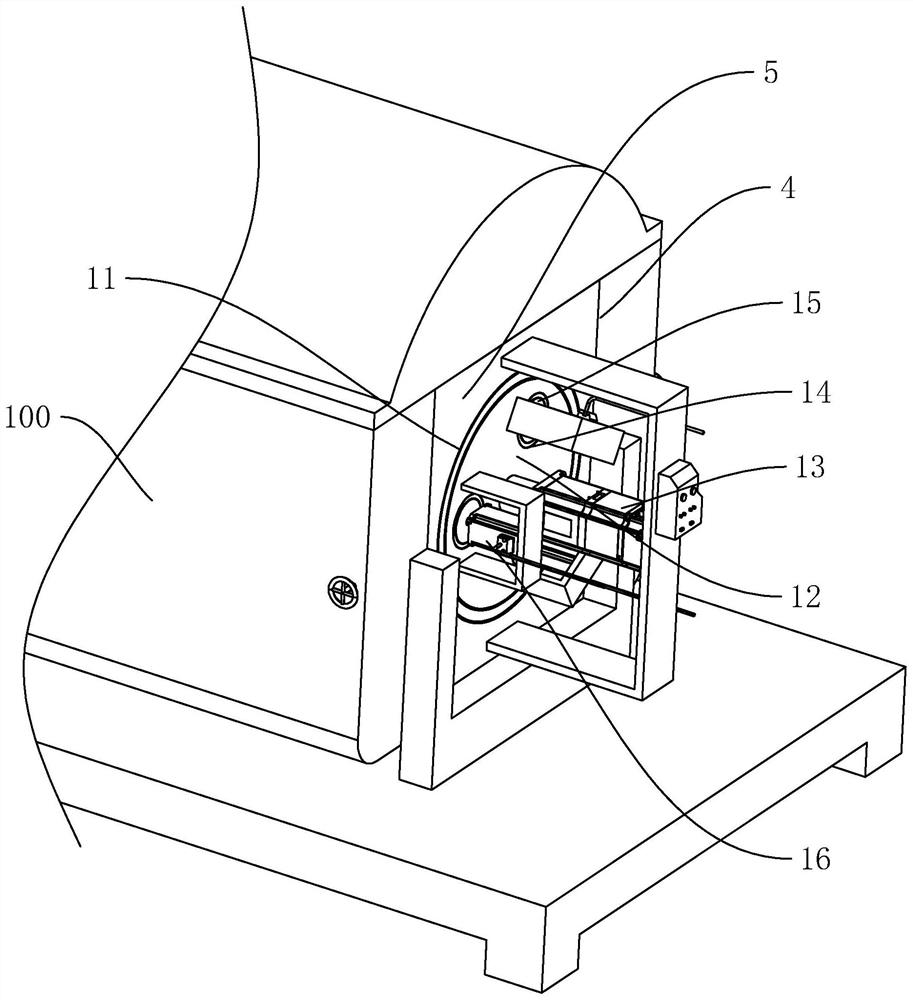

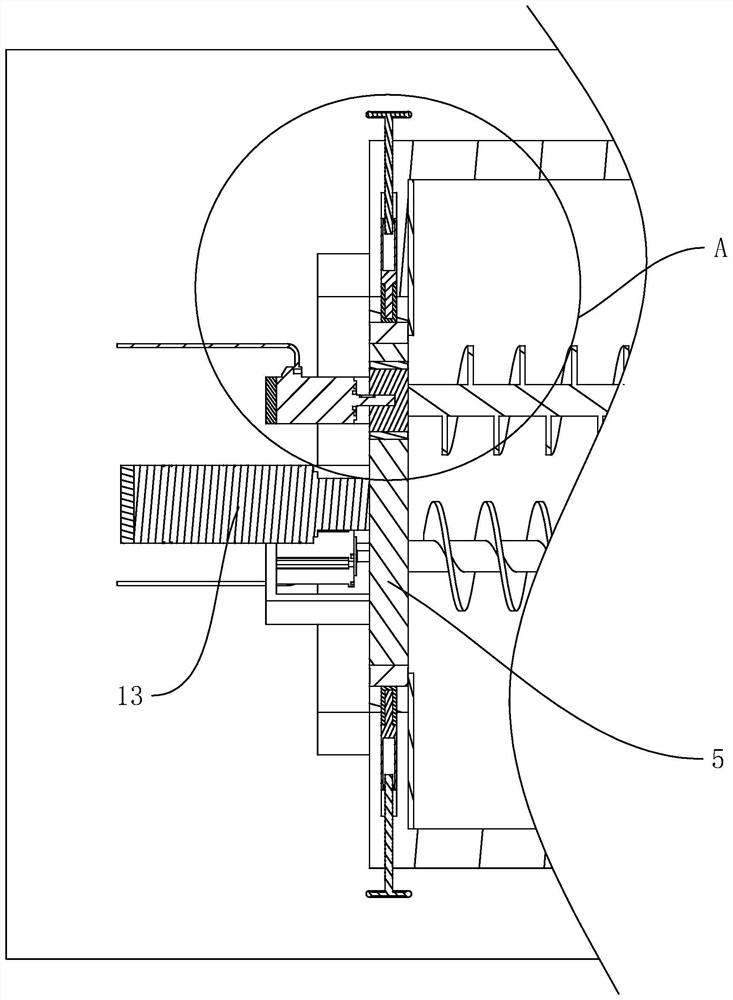

[0054] A kind of production equipment applied to the production process of current transformer in embodiment 1, with reference to image 3 and Figure 4 , The high-efficiency stirring tank 1 includes a tank body 100 and three stirring paddles 101 arranged in the tank body 100 .

[0055] Wherein, the tank body 100 is arranged as a cuboid, and a side wall of the tank body 100 is provided with an installation groove 4 , the inner cavity of the installation groove 4 is arranged in a cuboid shape and its notch is connected with the upper surface of the side wall of the tank body 100 .

[0056] refer to figure 2 A mounting plate 5 is detachably connected to the mounting groove 4, and the mounting plate 5 is arranged in a cuboid shape and can slide to cover the notch of the mounting groove 4.

[0057] refer to image 3 and Figure 4 , between the mounting plate 5 and the mounting groove 4 is provided with a fixing device 6 for fixing the mounting plate 5, the fixing device 6 inc...

Embodiment 3

[0074] Embodiment 3: a kind of production equipment applied to the production process of current transformer in embodiment 1, refer to Figure 6 The difference from Embodiment 2 is that the fixing device 6 includes a positioning rod 64 fixedly connected to the mounting plate 5 and a positioning groove 65 opened on the wall of the mounting groove 4 for inserting the positioning rod 64 . in. The positioning rod 64 is arranged in a cylindrical shape and arranged along a direction parallel to the surface of the mounting plate 5 .

[0075]When the mounting plate 5 is inserted into the mounting groove 4 , the positioning rod 64 is inserted into the positioning groove 65 , and the position of the mounting plate 5 is fixed when the positioning rod 64 is inserted into the positioning groove 65 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com