Organic electroluminescent device, display panel and display device

An electroluminescence device and electroluminescence technology, which are applied in electric solid devices, luminescent materials, electrical components, etc., can solve the problems of small display color gamut area and low color purity of devices, and achieve narrow emission spectrum and large display color gamut. Small area and Stokes displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

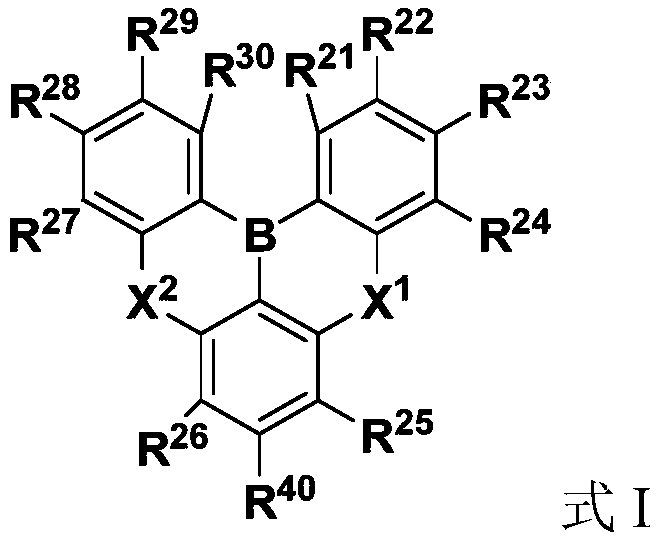

[0096] Synthesis Example 1: Synthesis of Compound C-1

[0097]

[0098] Under a nitrogen atmosphere, a pentane solution of tert-butyllithium (11.09mL, 1.60M, 17.74mmol) was slowly added to a solution of C-1-1 (8.00g, 14.79mmol) in tert-butylbenzene (150mL) at 0°C Then, the temperature was raised to 80°C, 100°C, and 120°C for 1 hour each. After the reaction, the temperature was lowered to -30°C, boron tribromide (5.56g, 22.18mmol) was slowly added, and stirring was continued for 0.5 hour at room temperature. N,N-diisopropylethylamine (3.82g, 29.57mmol) was added at room temperature, and the reaction was continued at 145°C for 5 hours and then stopped. The solvent was spin-dried in vacuo and passed through a silica gel column (developing solvent: ethyl acetate: petroleum ether = 50:1) to obtain target compound C-1 (1.00 g, 13% yield, HPLC analytical purity 99.56%) as a yellow solid. MALDI-TOF-MS results: molecular ion peak: 514.45; elemental analysis results: theoretical value: C...

Synthetic example 2

[0099] Synthesis Example 2: Synthesis of Compound C-2

[0100]

[0101] The difference between this example and Synthesis Example 1 is that in this example, C-1-1 needs to be replaced with C-2-1 in the same amount. The target compound C-2 (1.00 g, 13% yield, HPLC analytical purity 99.66%) was a yellow solid. MALDI-TOF-MS results: molecular ion peak: 512.45 Elemental analysis results: theoretical value: C, 84.39%; H, 4.33%; B, 2.11%; F, 3.71%; N, 5.47%; experimental value: C, 84.42 %; H, 4.01B, 2.52; F, 3.51%; N, 5.54%.

Synthetic example 3

[0102] Synthesis Example 3: Synthesis of Compound C-6

[0103]

[0104] The difference between this example and Synthesis Example 1 is that in this example, C-1-1 needs to be replaced with C-6-1 in the same amount. The target compound C-6 (0.62 g, 8% yield, HPLC analytical purity 99.56%), was a yellow solid. MALDI-TOF-MS results: molecular ion peak: 542.32 elemental analysis results: theoretical value: C, 79.72%; H, 3.72%; B, 1.99%; F, 3.50%; N, 5.17%; O, 5.90%; experiment Values: C, 79.77%; H, 3.72%; B, 1.94%; F, 3.55%; N, 5.17%; O, 5.85%.

PUM

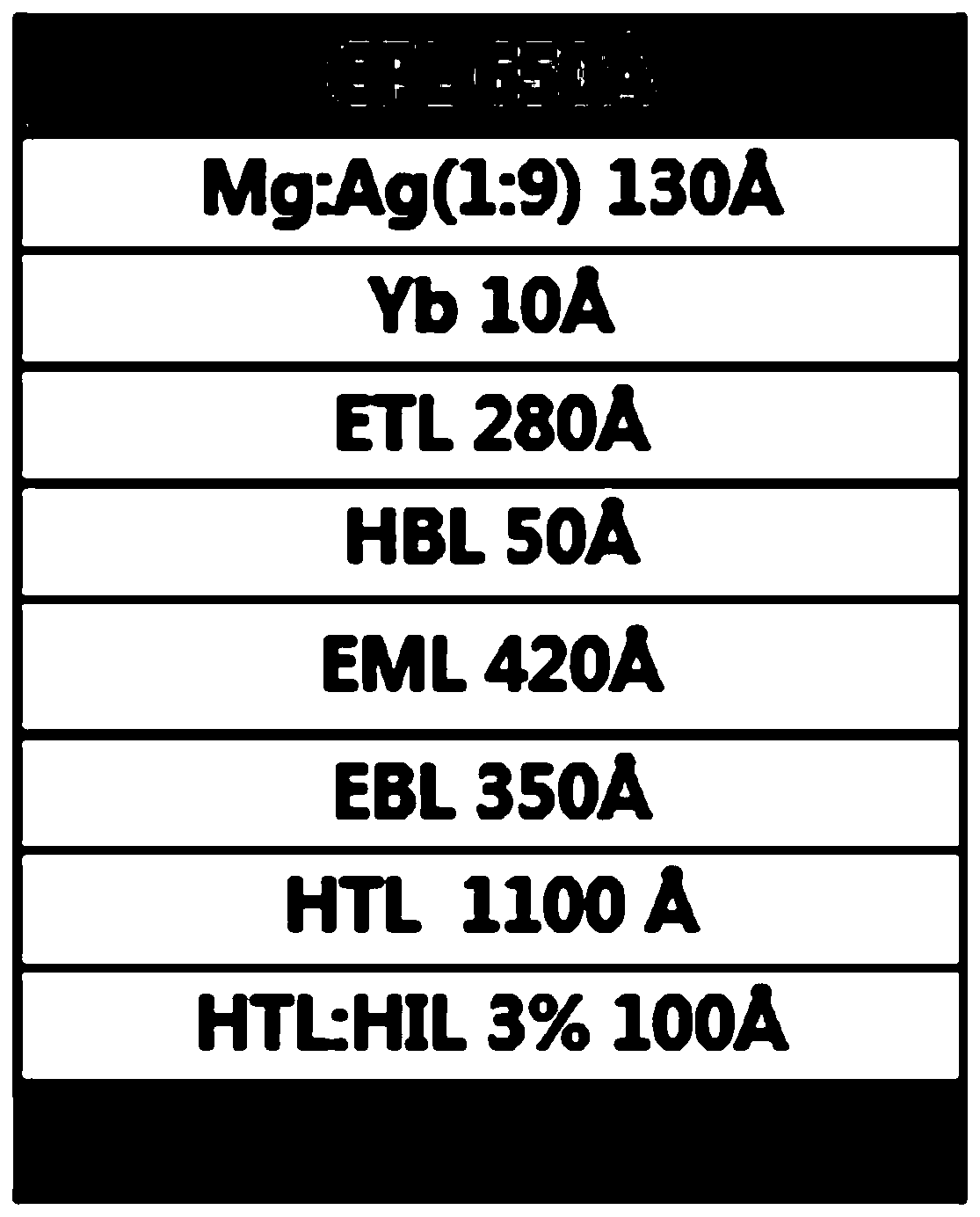

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com