Micro-rough electrolytic copper foil and copper foil substrate

A technology of electrolytic copper foil and copper foil substrate, applied in the direction of printed circuits, printed circuits, electrical components, etc., can solve the problems of falling peel strength between copper foil and substrate, reducing roughness, affecting the yield of back-end products, etc. Achieve good bonding force, suppress loss, and good insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

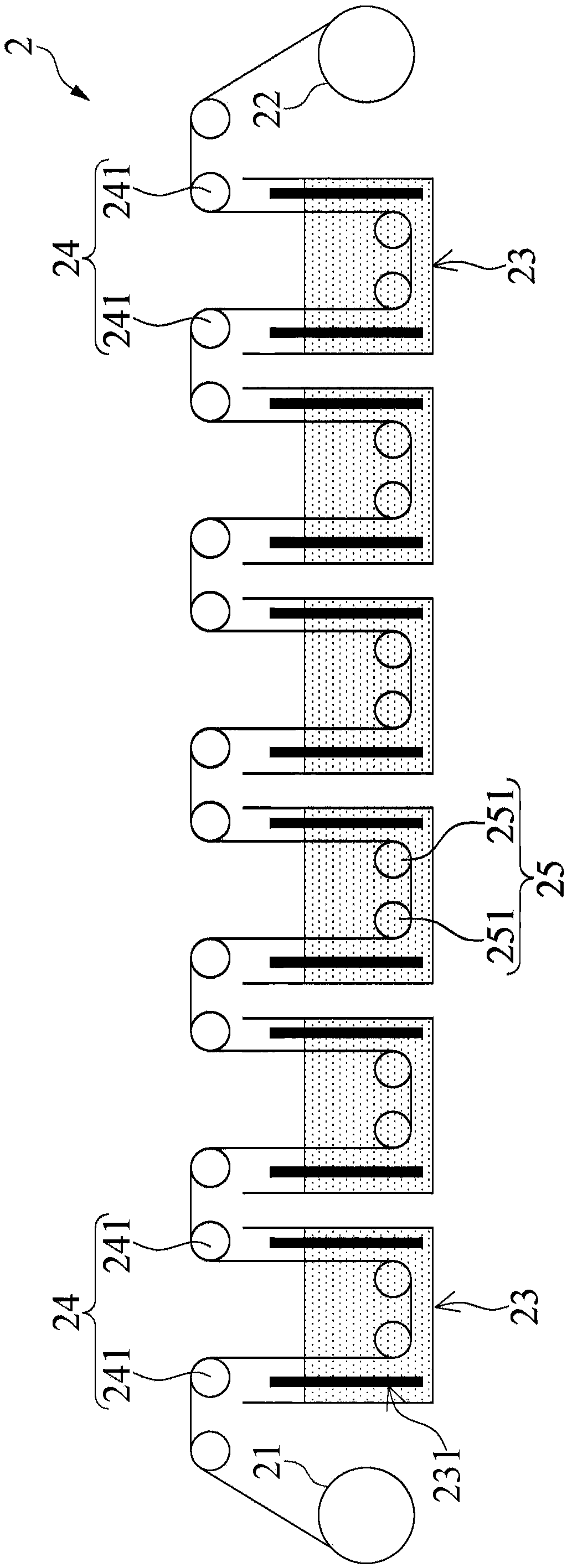

[0045] refer to image 3 , Micro-rough electrolytic copper foil is roughened by continuous electrolytic equipment 2. The continuous electrolysis equipment 2 comprises a feeding roller 21, a collecting roller 22, six grooves 23 between the feeding roller 21 and the collecting roller 22, six electrolytic roller groups 24 placed respectively above the groove 23, And six auxiliary roller groups 25 respectively located in the grooves 23. A set of platinum electrodes 231 is disposed in each groove 23 . Each electrolytic roller group 24 includes two electrolytic rollers 241. Each auxiliary roller set 25 includes two auxiliary rollers 251 . The platinum electrode 231 in each tank 23 and the corresponding electrolytic roller set 24 are respectively electrically connected to the anode and the cathode of the external power supply.

[0046] In this embodiment 1, reversed copper foil (RTF) was used as the raw foil, which was purchased from Jinju Development Co., Ltd. (model RG311). Th...

Embodiment 2 and 3

[0052] The components of raw foil, electrolytic equipment and copper-containing plating solution are the same as in Example 1, the electroplating conditions are shown in Table 1, and the production speed is 10 m / min. Then, take two pieces of micro-rough electrolytic copper foil and one piece of base material IT170GRA1 and stick them together to complete the production. The measurement method is the same as in Example 1, and the test results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com