Connector

A connector and pipeline technology, applied in the direction of adjustable connection, indirect heat exchanger, sealing surface connection, etc., can solve the problems of slow and sufficient temperature control, complex cost, limited and other problems, and achieve rapid manufacturing, cheap manufacturing, and space saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

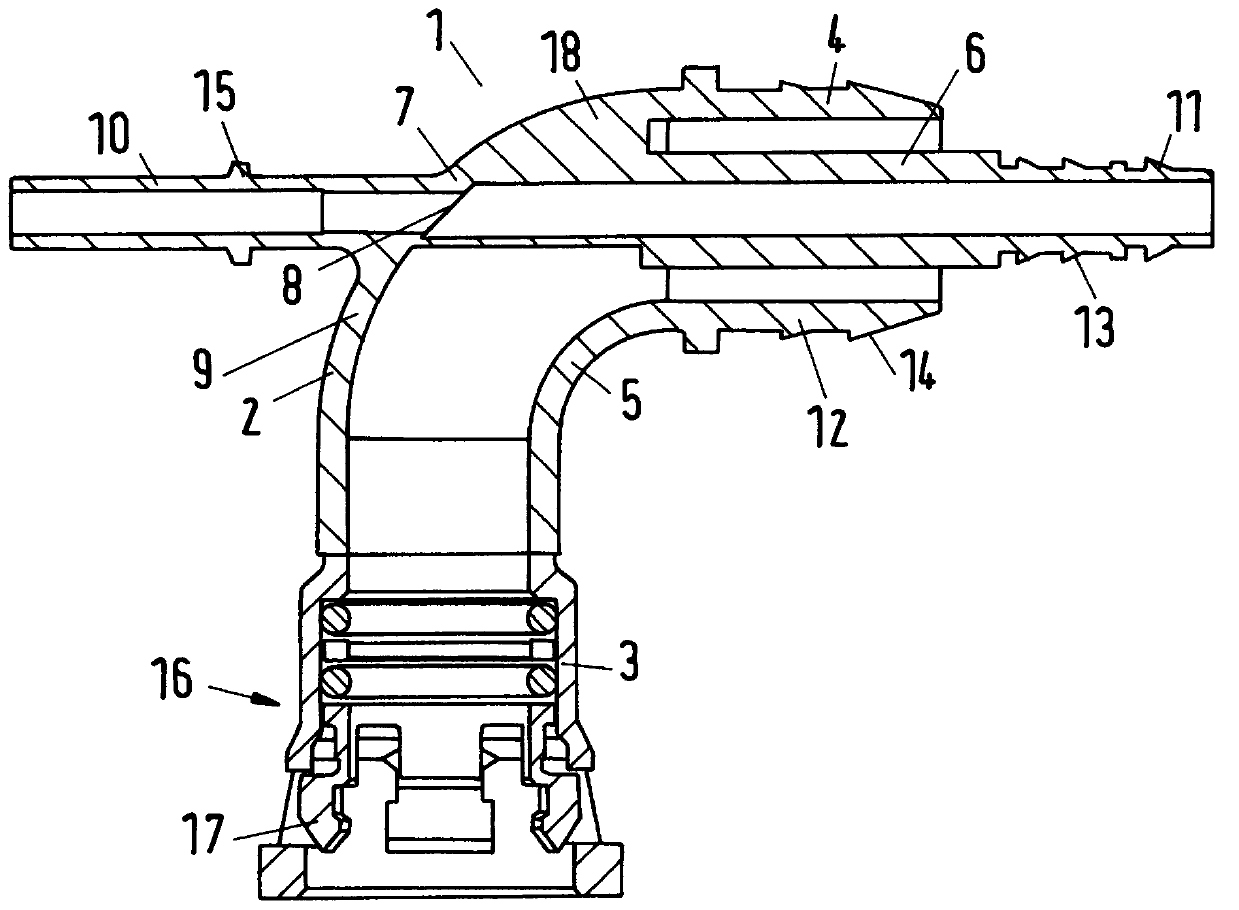

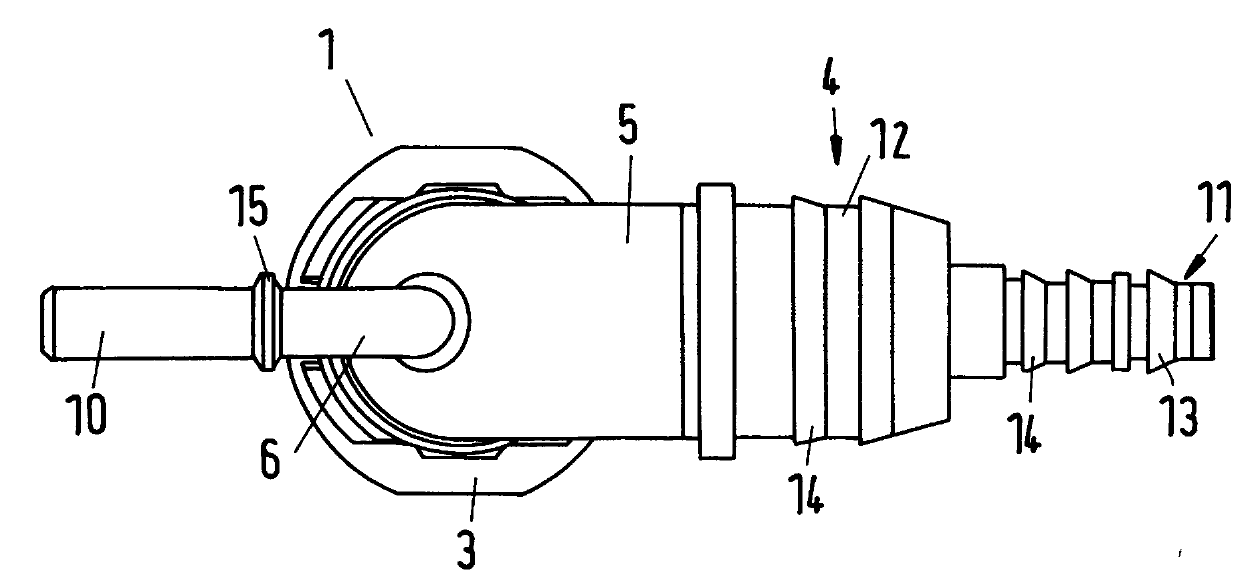

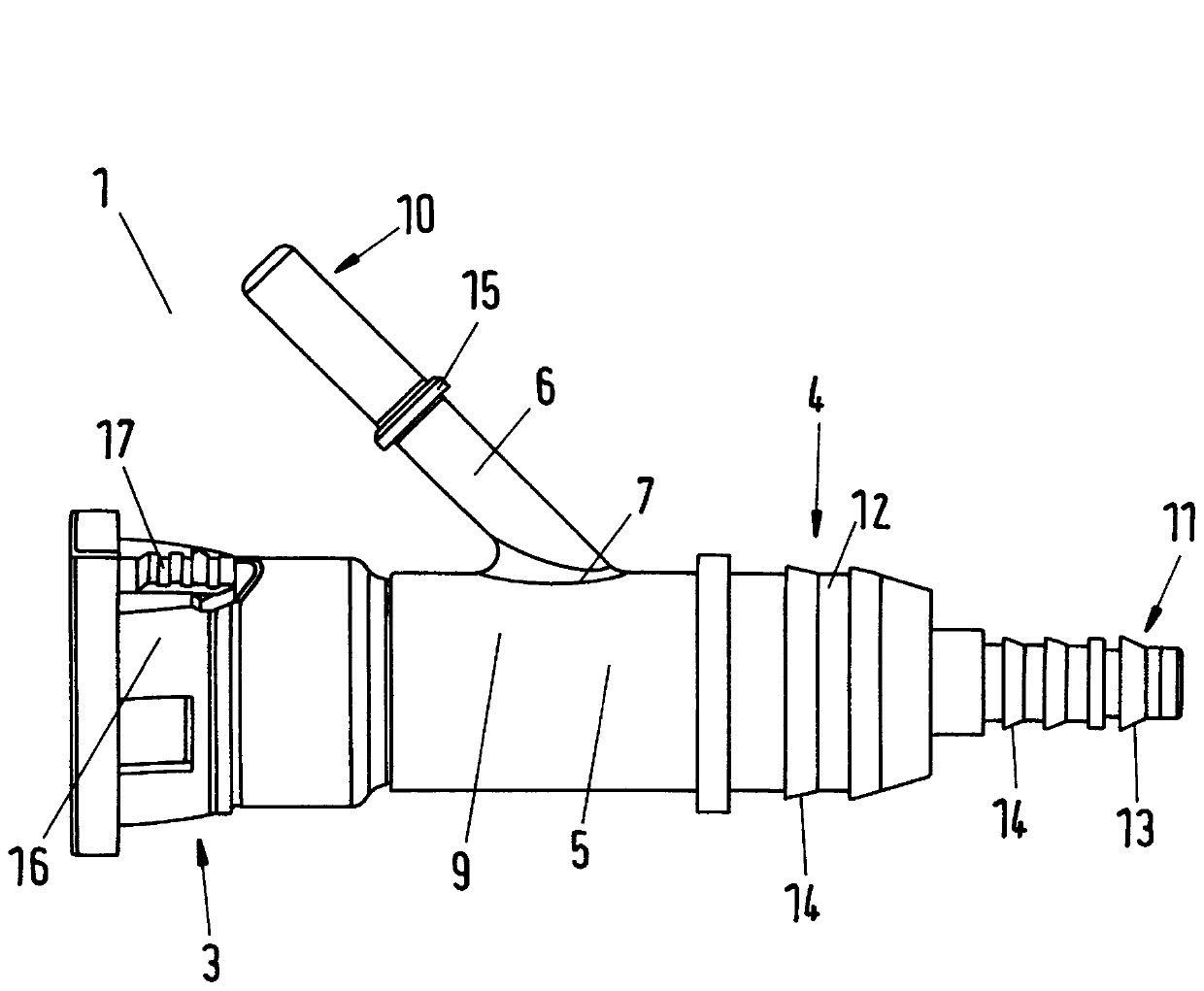

[0031] figure 1 A connector 1 according to the invention is shown, comprising a housing 2 . The housing 2 has a first end 3 and a second end 4 between which a first conduit 5 for a first fluid is arranged. A second conduit 6 for a second fluid is arranged at least partially within said first conduit 5 and exits coaxially through said second end 4 . The housing 2 has an outlet 7 with an outlet opening 8 through which the second conduit 6 leaves the housing 2 . The outlet portion 7 with the outlet opening 8 is arranged in a wall 9 of the first duct 5 .

[0032] Through the outlet opening 8 in the outlet section 7 the second conduit 6 for a second fluid is introduced into the first conduit 5 . A line-in-line system is thus formed. Here, the fluid systems of the first fluid and the second fluid are arranged separately from each other. The arrangement of the first conduit 5 and the second conduit 6 in the connector is realized such that they are completely fluid-tight and flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com