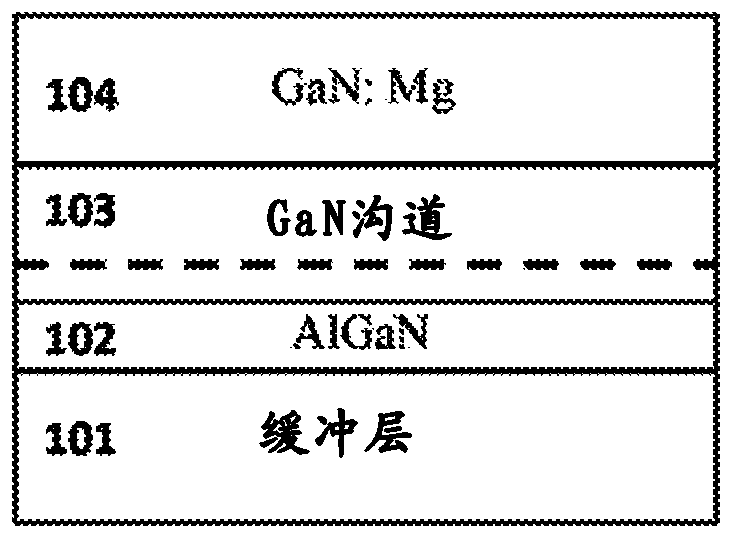

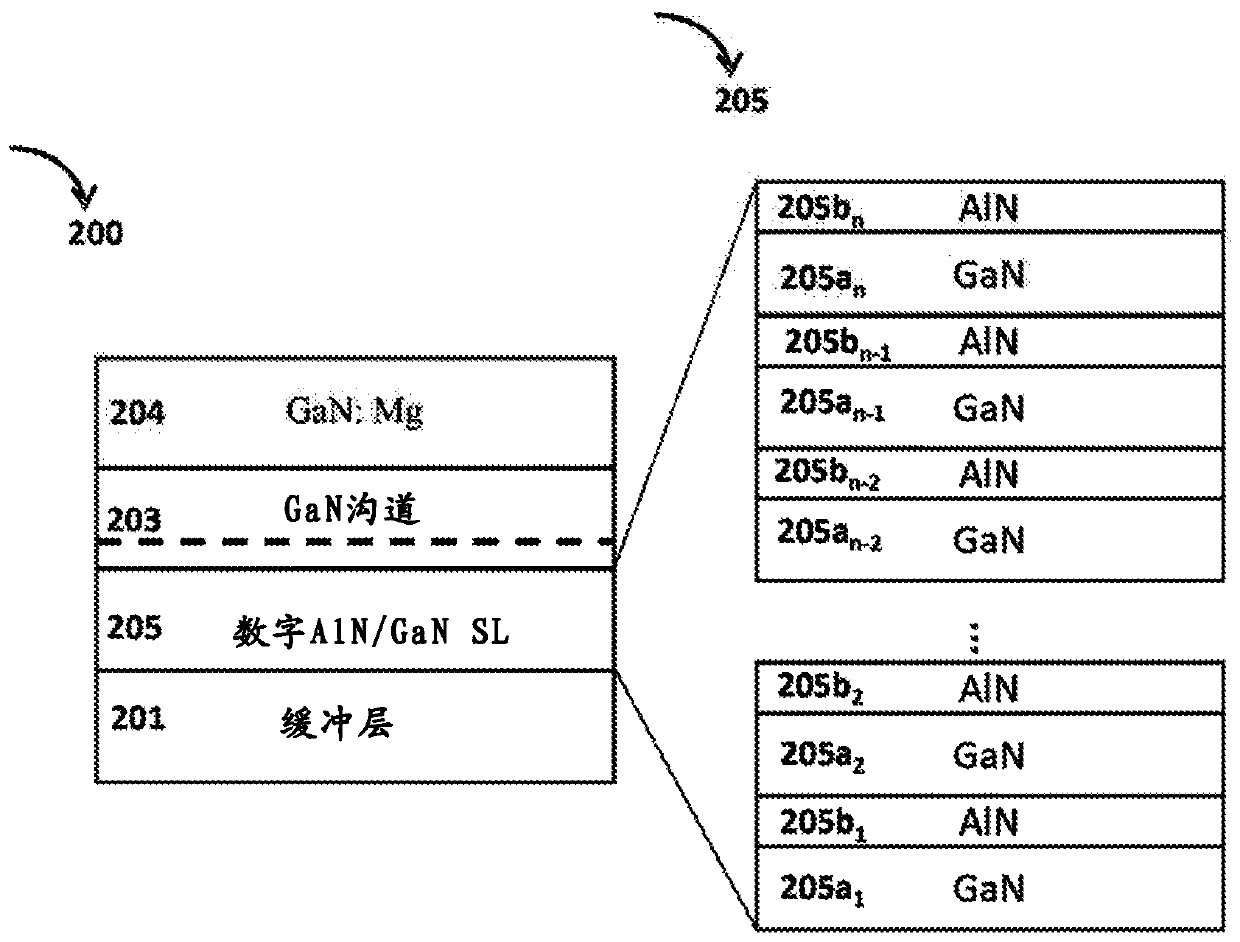

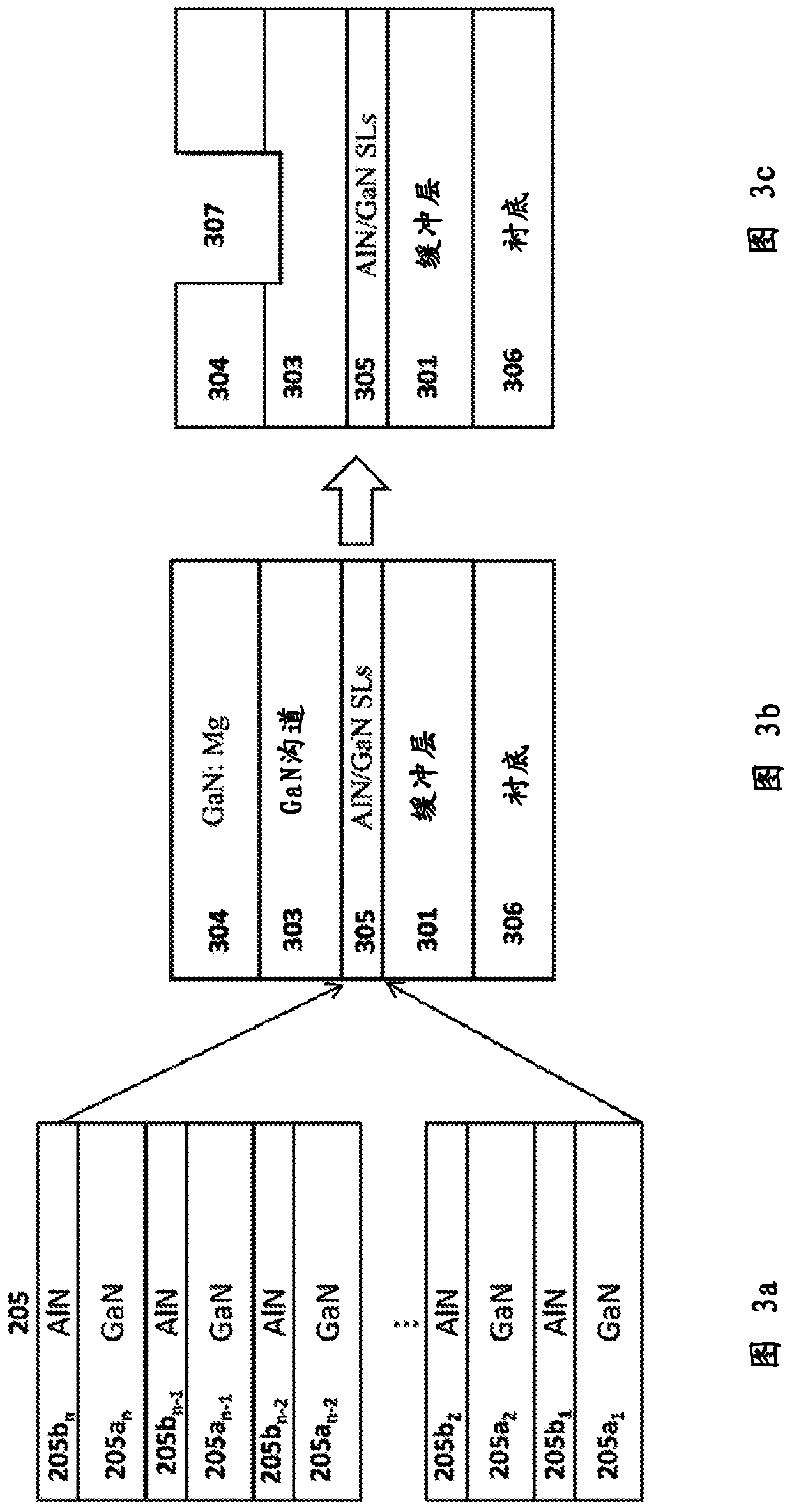

Digital alloy based back barrier for p-channel nitride transistors

A nitride, back-barrier technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as lattice mismatch and growth of thick analog AlGaN

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be understood at the outset that although exemplary embodiments are shown below, the technology may be implemented using any number of techniques, whether currently known or not. The technology should by no means be limited to the exemplary embodiments, figures and techniques described below. Additionally, the drawings are not necessarily drawn to scale.

[0044] Recently, GaN transistors have revolutionized high-power and high-speed switching electronics, and application demands continue to drive higher and higher power-handling capabilities. The power handling capability of a GaN transistor is directly dependent on the channel conductivity.

[0045] Group III nitride semiconductor materials (aluminum, indium, gallium) nitrides are excellent wide bandgap semiconductors well suited for modern electronic and optoelectronic applications. Although the present invention describes techniques using GaN, the presented techniques are applicable to any Ill-nitride se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com