A preparation method of a novel structured emulsion that improves the oxidation stability of fats and oils

A technology of oil oxidation and new structure, applied in the production/processing of edible oil/fat, emulsion transportation, cosmetic preparations, etc., can solve the problems of oil easy oxidation, bad flavor, etc. The effect of wide range and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 beeswax structure:

[0042] (1) Accurately weigh 0.32g of hydroxypropyl cellulose and 0.16g of xanthan gum in 60g of water according to the mass ratio of 2:1, and stir in a water bath (80°C) until completely dissolved to prepare water phase A;

[0043] (2) Accurately weigh 2.0 g of beeswax and 40 g of linseed oil, heat and stir at 80°C for 5 minutes to completely dissolve the beeswax, and obtain oil phase B;

[0044] (3) Mix the oil phase B with the water phase A, and prepare colostrum C (10000rpm / 1min) with a high-speed shear disperser (AD500S-P);

[0045] (4) Put colostrum C in a high-pressure homogenizer to prepare emulsion D (100Mpa, three cycles);

[0046] (5) Store the emulsion D at the crystallization temperature (4°C) for 24 hours to obtain the beeswax structured emulsion.

[0047] Embodiment 1 formula composition:

[0048]

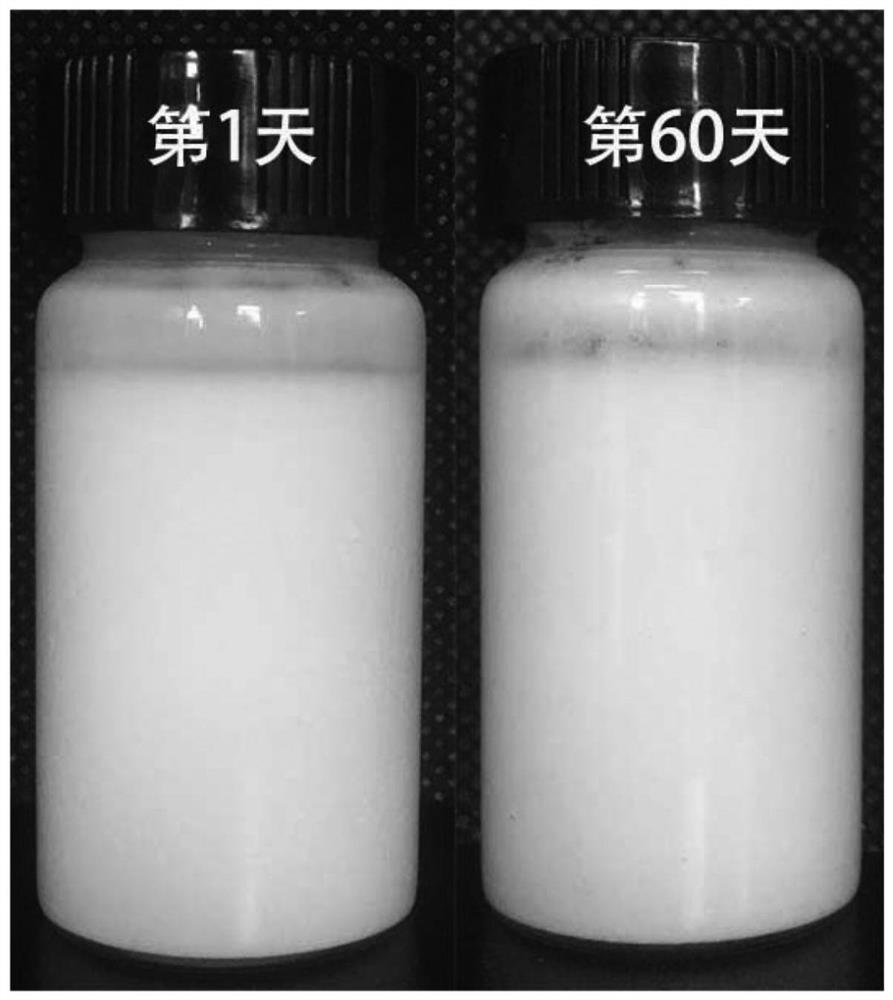

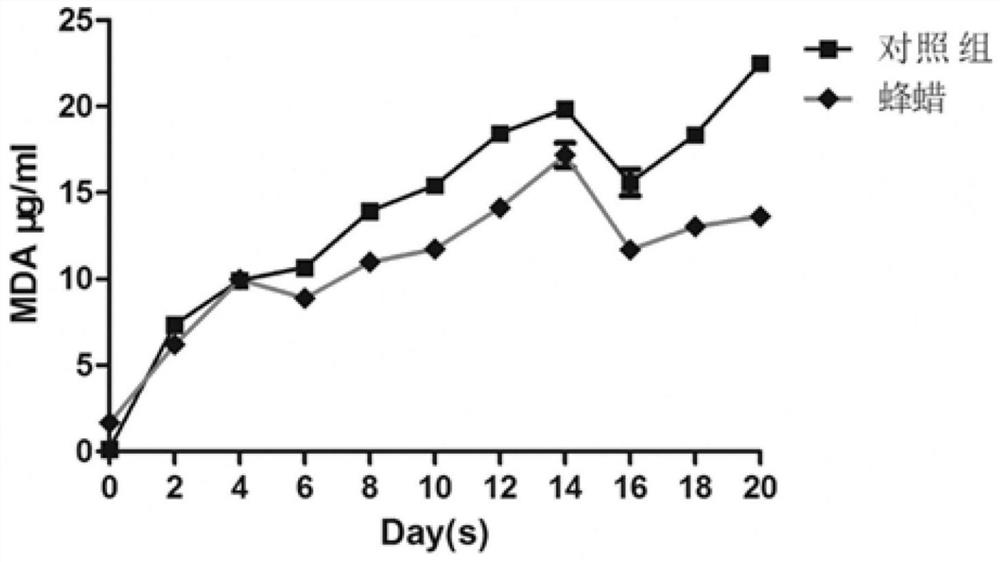

[0049] Depend on figure 1 It can be seen that the prepared structured emulsion is an oil-in-water e...

Embodiment 2

[0053] The preparation of embodiment 2 different crystallization temperature stearic acid structured emulsion:

[0054] (1) Accurately weigh 0.3g of hydroxypropyl cellulose and 0.3g of sodium lauryl sulfate in 60g of water according to the mass ratio of 1:1, and stir in a water bath (90°C) until completely dissolved to prepare water phase A;

[0055] (2) Accurately weigh 6.0g of stearic acid and 40g of perilla seed oil, heat and stir at 90°C for 10min to completely dissolve stearic acid, and obtain oil phase B;

[0056] (3) Mix the oil phase B with the water phase A, and prepare colostrum C (10000rpm / 1min) with a high-speed shear disperser (AD500S-P);

[0057](4) Put colostrum C in a high-pressure homogenizer to prepare emulsion D (100Mpa, three cycles);

[0058] (5) Store the emulsion D at the crystallization temperature (4°C, 20°C) for 24 hours to obtain the stearic acid structured emulsion.

[0059] Embodiment 2 formula composition:

[0060]

[0061]

[0062] Depen...

Embodiment 3

[0066] The preparation of embodiment 3 different concentrations stearic acid structured emulsion:

[0067] (1) Accurately weigh 0.44g of Tween-80 and 0.22g of sodium lauryl sulfate in 65g of water according to the mass ratio of 2:1, and stir in a water bath (75°C) until completely dissolved to prepare water phase A;

[0068] (2) Accurately weigh 1.75g, 3.5g, 5.25g of stearic acid and 35g of perilla seed oil, heat and stir at 75°C for 10min to completely dissolve stearic acid, and obtain oil phase B;

[0069] (3) Mix the oil phase B with the water phase A, and prepare colostrum C (10000rpm / 1min) with a high-speed shear disperser (AD500S-P);

[0070] (4) Put colostrum C in a high-pressure homogenizer to prepare emulsion D (100Mpa, three cycles);

[0071] (5) Store the emulsion D at the crystallization temperature (20°C) for 24 hours to obtain the stearic acid structured emulsion.

[0072] Embodiment 3 formula forms:

[0073]

[0074] Depend on Figure 7 It can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com