Preparation process of raw baked bamboo shoot tea and raw baked bamboo shoot tea

A production process and technology of roasting bamboo shoots, applied in the field of food processing, can solve the problems of lactone loss, poor taste, long rehydration time, etc., achieve the effect of short brewing time, save water and wood, and fast rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

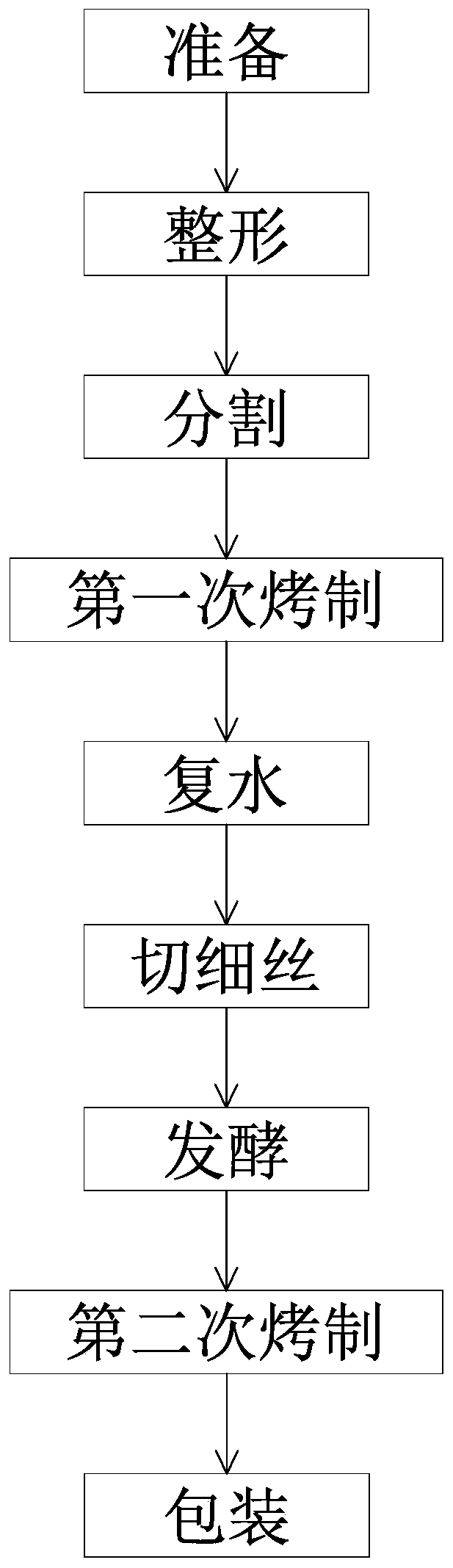

[0031] Such as figure 1 Shown, the manufacture craft of raw roasted bamboo shoot tea comprises the following steps:

[0032] S1 is ready to dig and shell to obtain complete fresh bamboo shoots.

[0033] S2 Shaping Peel off the shell of the bamboo shoots, and cut off the inedible parts of the heads and tails of the bamboo shoots.

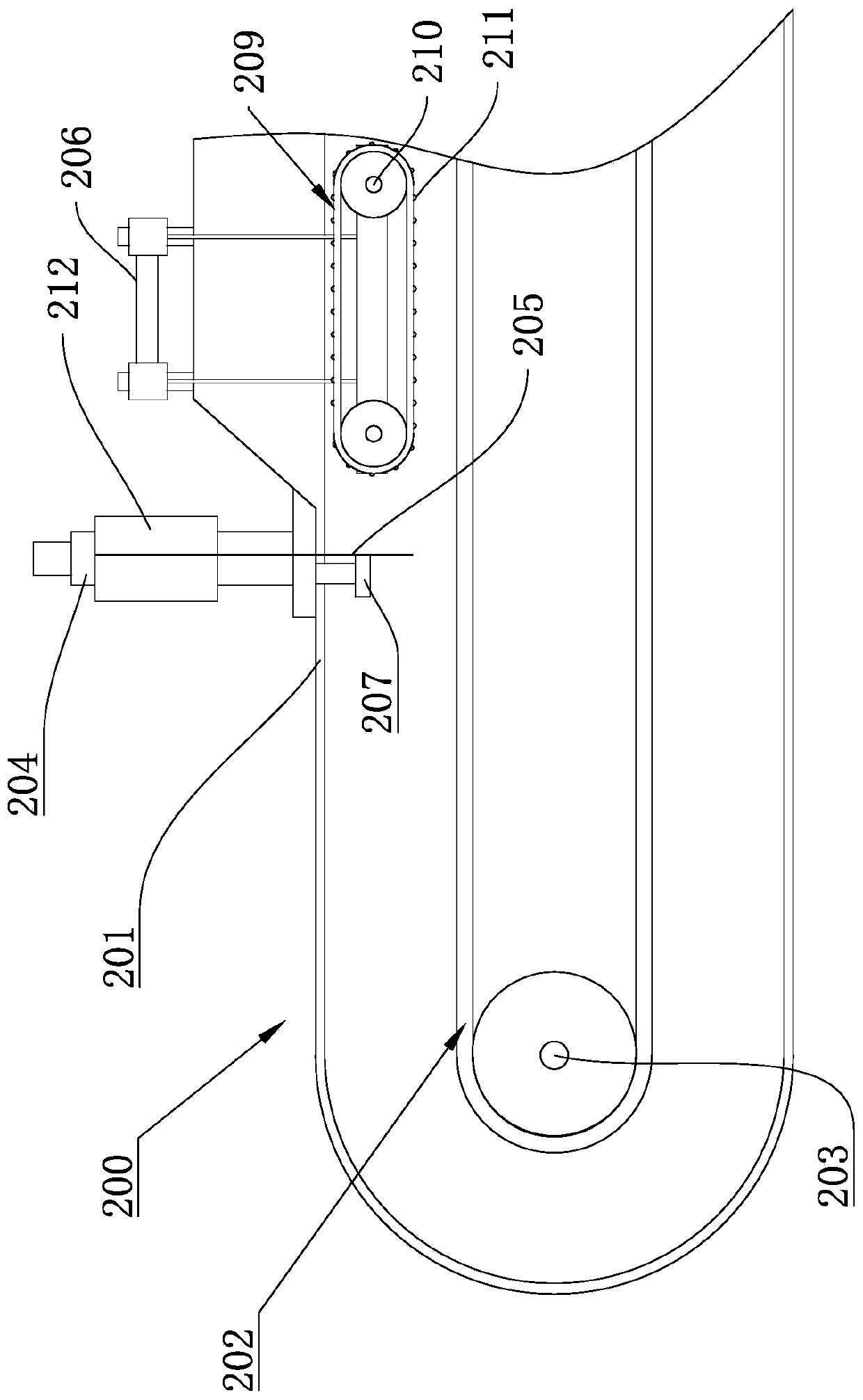

[0034] S3 Segmentation In order to facilitate baking, the shaped bamboo shoots are divided into bamboo shoots. In this embodiment, the bamboo shoots are cut into bamboo shoots with a length of 30 mm to 50 mm, a width of 10 mm to 20 mm, and a thickness of 10 mm to 20 mm.

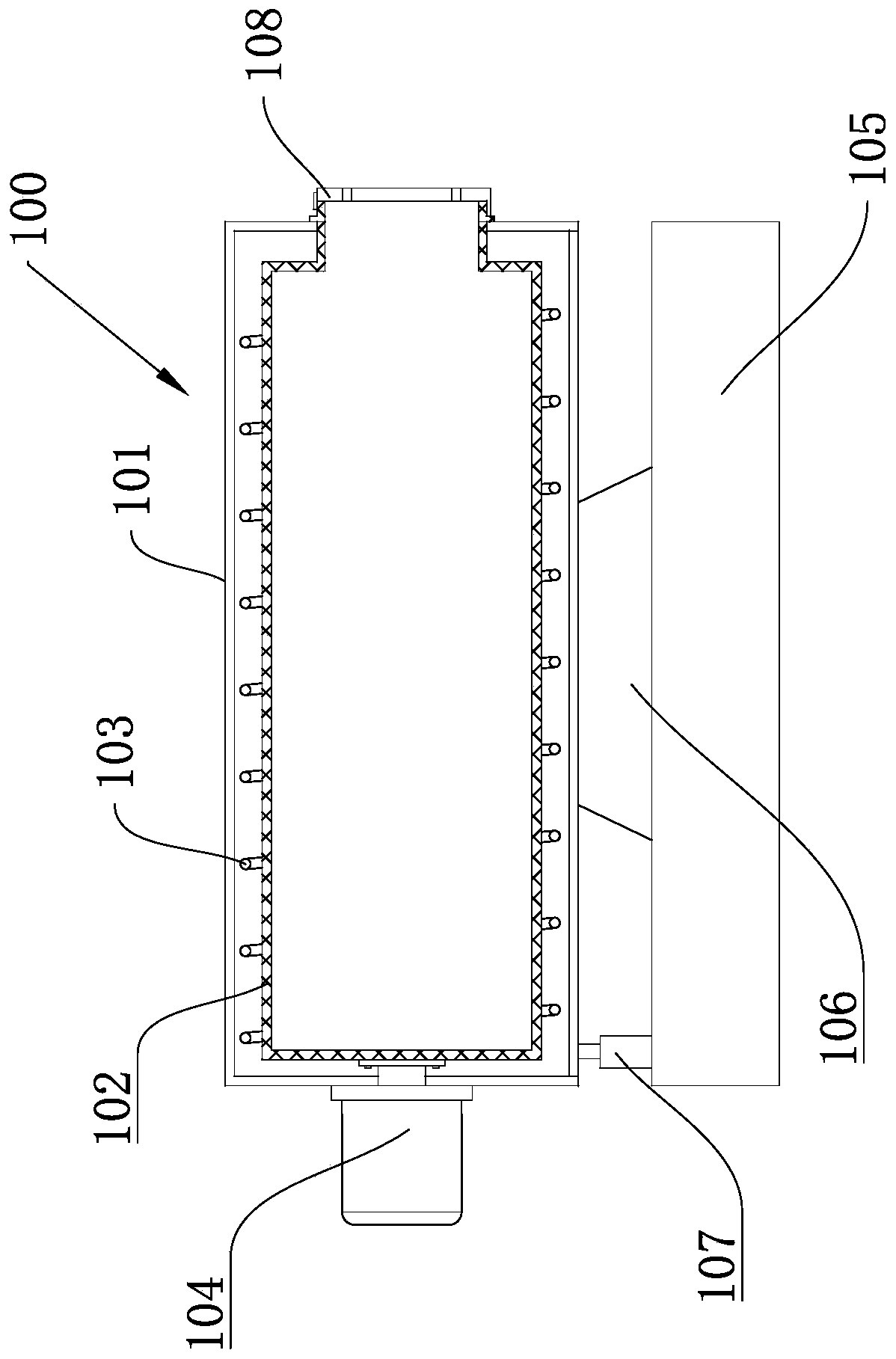

[0035] S4 The first roasting adopts cylinder drying equipment to roast the cut bamboo shoots. In this embodiment, the first roasting temperature is set at 75° C., and the roasting time is 12 hours.

[0036] The temperature range for the first roasting is 50°C to 75°C, and the roasting time is selected in the range of 6h to 24h according to the volume of the bamboo shoots. Baking f...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, except that: the first baking temperature is set at 50° C., and the baking time is 24 hours; the second baking temperature is set at 45° C., and the baking time is 10 hours.

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, except that: the first baking temperature is set to 65° C., and the baking time is 6 hours; the second baking temperature is set to 60° C., and the baking time is 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com